Well-designed China Fiberglass Composite Materials Expo

With advanced technologies and facilities, strict high quality control, reasonable value, exceptional company and close co-operation with prospects, we’ve been devoted to offering the very best worth for our consumers for Well-designed China Fiberglass Composite Materials Expo, Our business has already setup a professional, creative and responsible workforce to develop purchasers together with the multi-win principle.

With advanced technologies and facilities, strict high quality control, reasonable value, exceptional company and close co-operation with prospects, we’ve been devoted to offering the very best worth for our consumers for China Fiberglass Combination Mat, Glass Fiber, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

E-glass Assembled Panel Roving

Assembled Panel Roving is coated with a silane-based sizing compatible with UP. It can wet out fast in resin and deliver excellent dispersion after chopping.

Features

●Light weight

●High strength

●Excellent impact resistance

●No white fiber

●High translucency

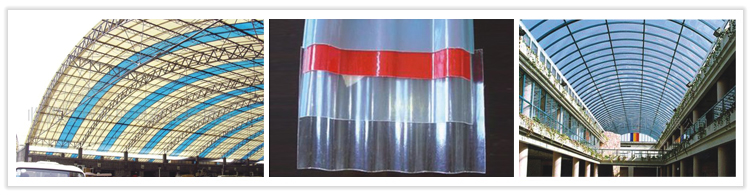

Application

It can be used to manufacture lighting boards in building & construction industry.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHP-01A |

2400, 4800 |

UP |

low static, moderate wet out, excellent dispersion |

translucent and opaque panels |

|

BHP-02A |

2400, 4800 |

UP |

extremely fast wet-out, superior transparency |

high transparency panel |

|

BHP-03A |

2400, 4800 |

UP |

low static, fast wet out, no white fiber |

general purpose |

|

BHP-04A |

2400 |

UP |

good dispersion, good anti-static property, excellent wet-out |

transparent panels |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

12, 13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.15 |

0.60±0.15 |

115±20 |

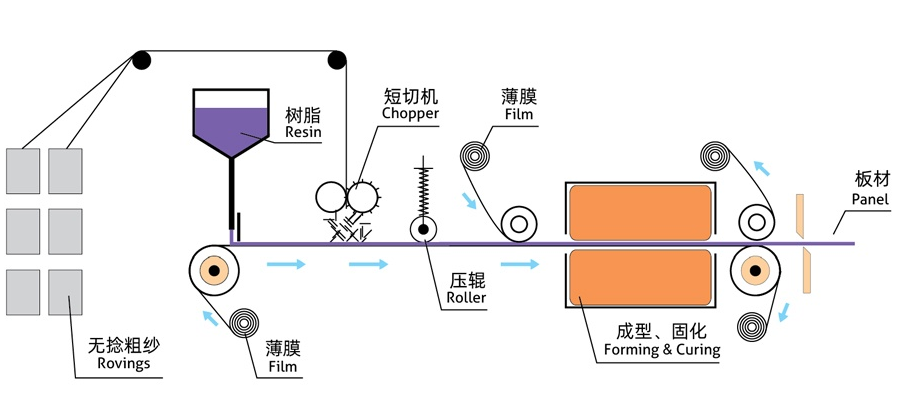

Continuous Panel Moulding process

A resin mix is uniformly deposited in a controlled amount onto the moving film at the constant speed . The thickness of the resin is controlled by the draw-knife . The fiberglass roving is chopped and uniformly distributed onto the resin, then a top film is applied forming a sandwich structure . The wet assembly travels through the curing oven to form the composite panel.

With advanced technologies and facilities, strict high quality control, reasonable value, exceptional company and close co-operation with prospects, we’ve been devoted to offering the very best worth for our consumers for Well-designed China Fiberglass Composite Materials Expo, Our business has already setup a professional, creative and responsible workforce to develop purchasers together with the multi-win principle.

Well-designed China Fiberglass Combination Mat, Glass Fiber, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.