-

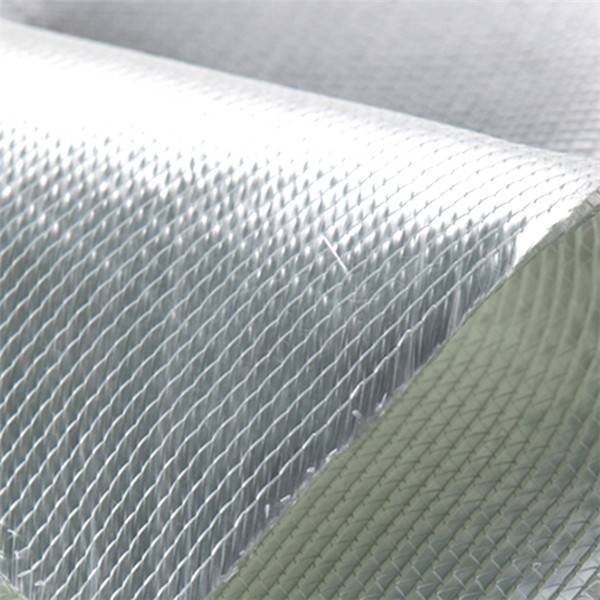

Fiberglass Surface Veil Stitched Combo Mat

Fiberglass Surface Veil Stitched Combo Mat is one layer of surface veil(fiberglass veil or polyester veil) combined with various of fiberglass fabrics, multiaxials and chopped roving layer by stitching them together. The base material can be only one layer or several layers of different combinations. It can be mainly applied in pultrusion, resin transfer molding, continuous board making and other forming processes. -

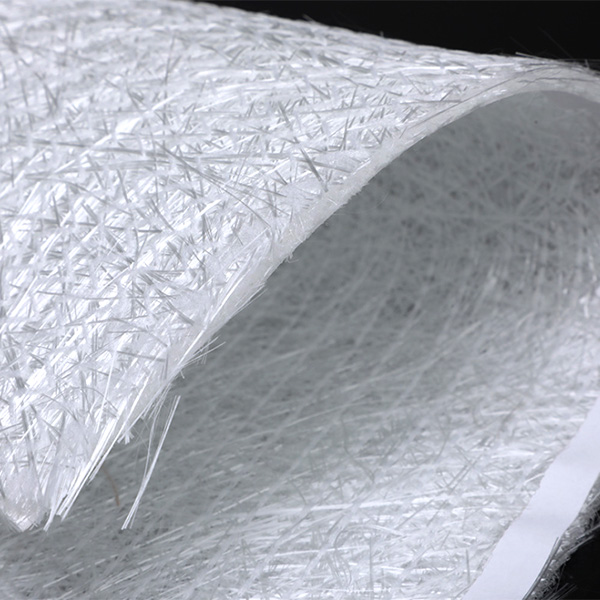

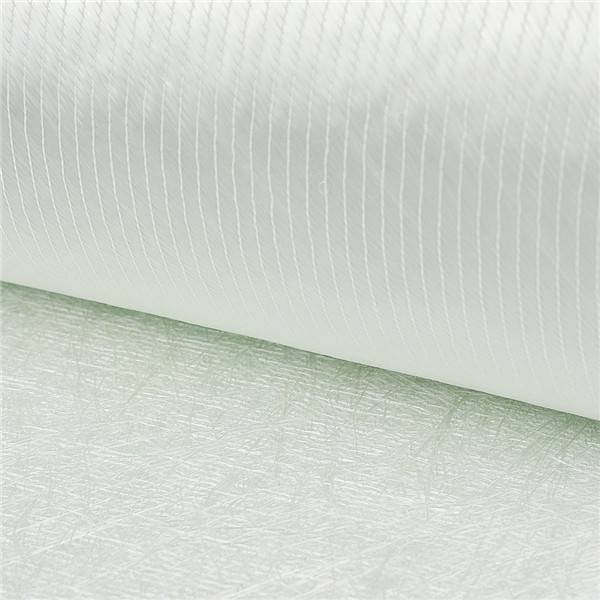

Fiberglass Stitched Mat

Stitched mat is made of chopped fiberglass strands randomly dispersed and laid on the forming belt, stitched together by a polyester yarn. Mainly used for

Pultrusion, Filament Winding, Hand Lay-up and RTM molding process, applied to FRP pipe and storage tank, etc. -

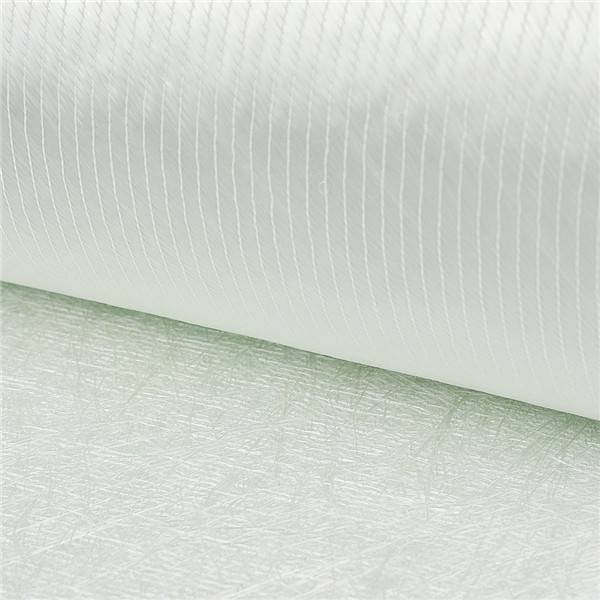

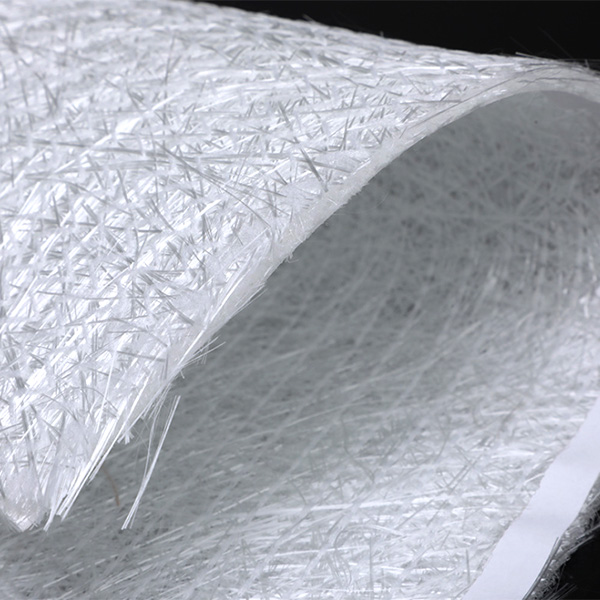

Fiberglass Core Mat

Core Mat is a new material, consisting of a synthetic non-woven core,sandwiched between two layers of chopped glass fibers or one layer of chopped glas fibers and the other one layer of multiaxial fabric/woven roving. Mainly used for RTM, Vacuum Forming, Molding, Injection Molding and SRIM Molding process, applied to FRP boat, automobile, aeroplane, panel, etc. -

PP Core Mat

1.Items 300/180/300,450/250/450,600/250/600 and etc

2.Width: 250mm to 2600mm or sub multiple cuts

3.Roll Length:50 to 60 meters according to the areal weight -

Triaxial Fabric Longitudinal Triaxial(0°+45°-45°)

1.Three layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.Used in blades of wind power turbines, boat manufacturing and sports advices. -

Biaxial Fabric +45°-45°

1.Two layers of rovings(450g/㎡-850g/㎡)are aligned at +45°/-45°

2.With or without a layer of chopped strands(0g/㎡-500g/㎡).

3.Maximum width of 100 inches.

4.Used in boat manufacturing. -

Triaxial Fabric Transverse Trixial(+45°90°-45°)

1.Three layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.It is used in blades of wind power turbines, boat manufacturing and sports advices. -

Quataxial(0°+45°90°-45°)

1.At most 4 layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.It is used in blades of wind power turbines, boat manufacturing and sports advices. -

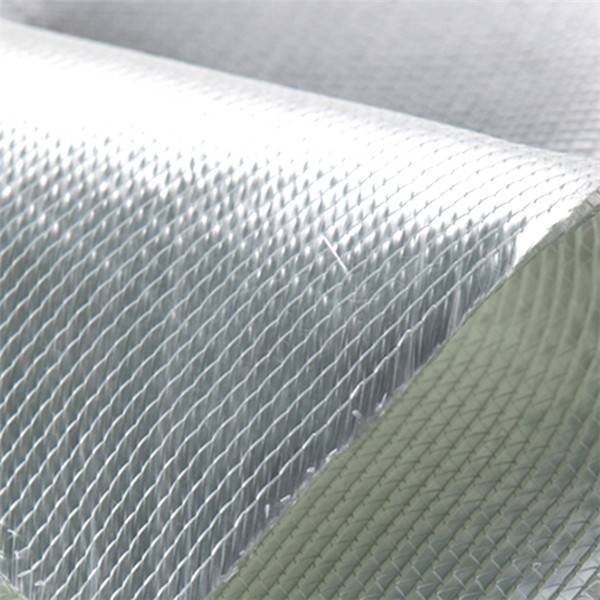

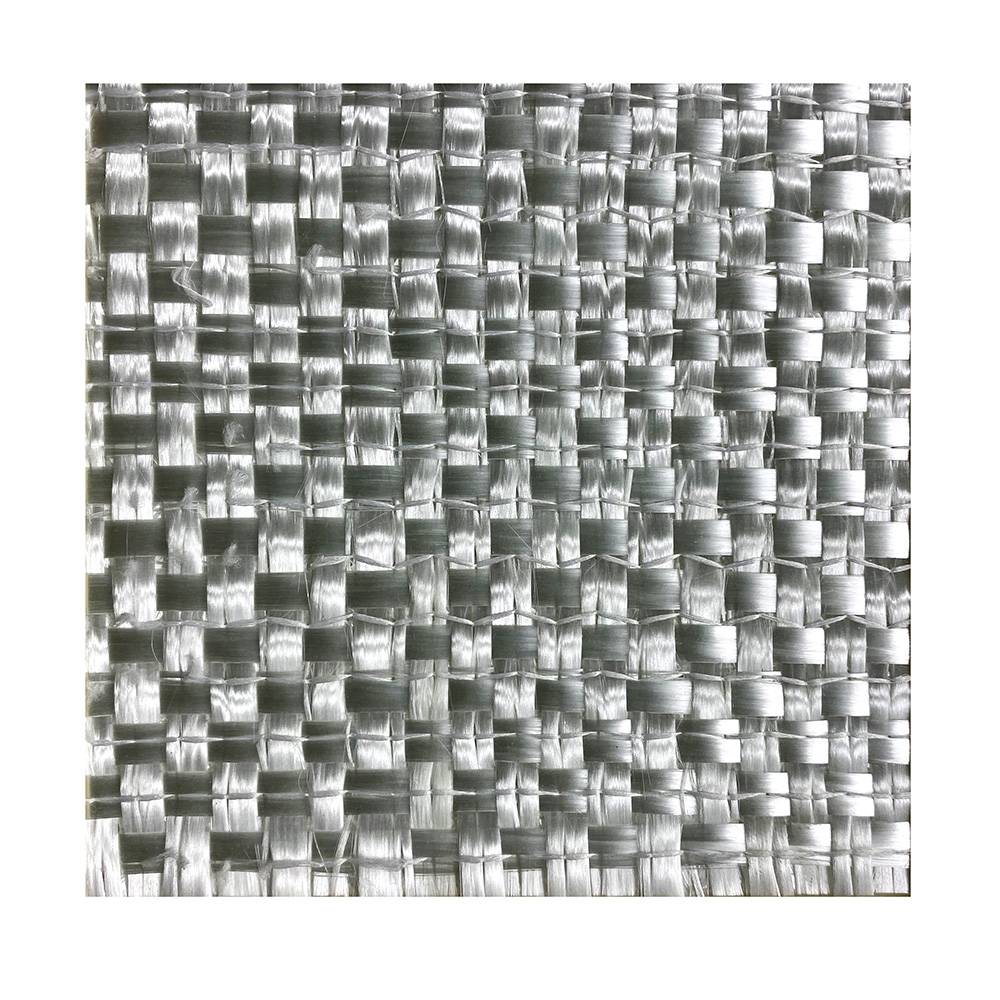

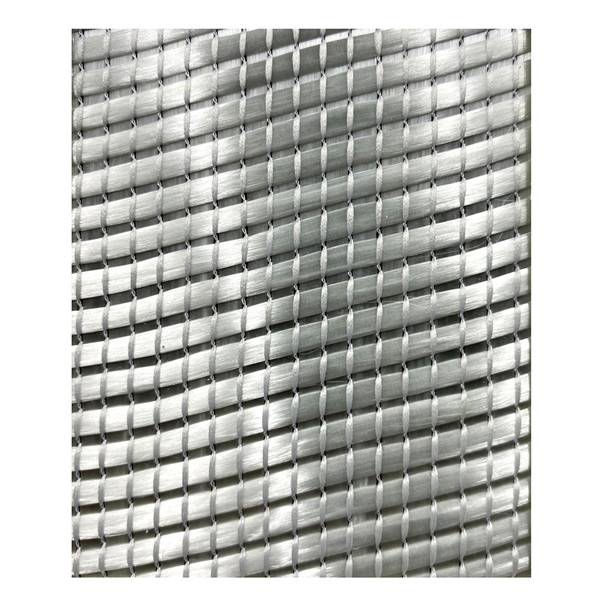

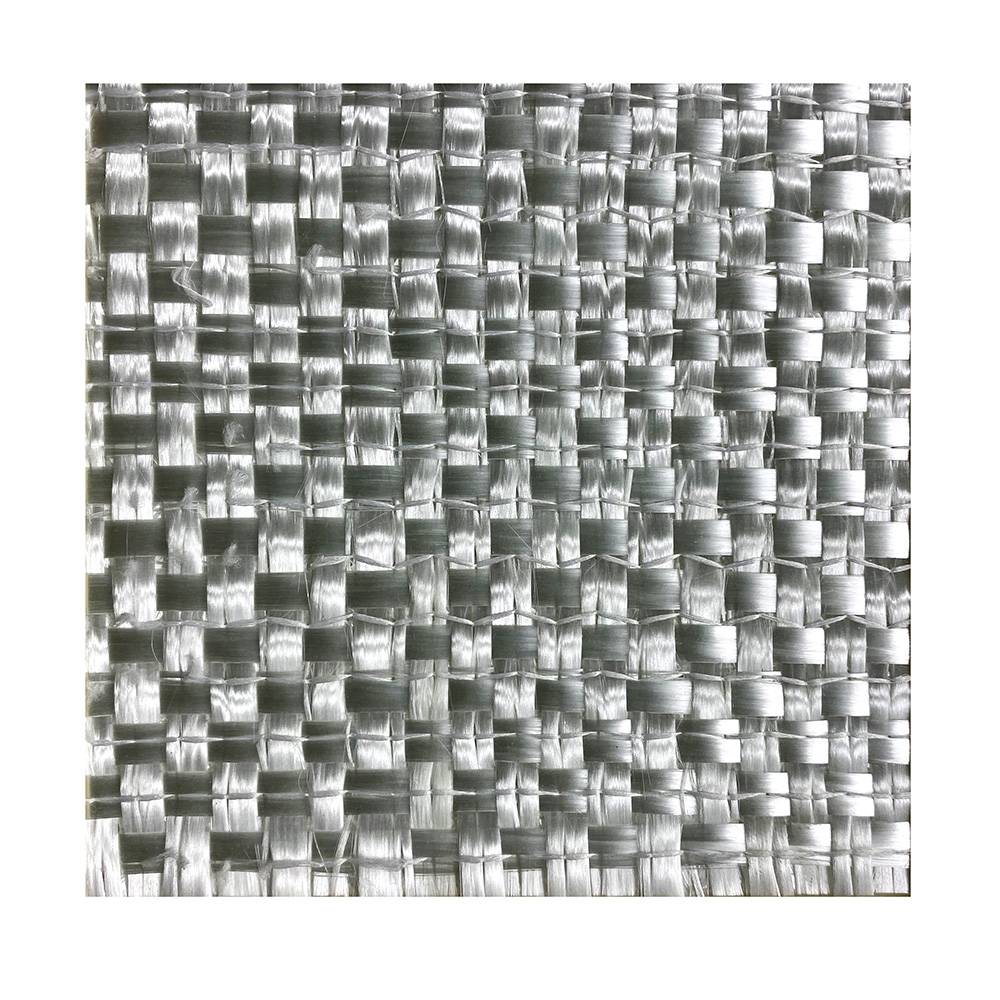

Woven Roving Combo Mat

1.It is knitted with two levels, fiberglass woven fabric and chop mat.

2.Areal weight 300-900g/m2, chop mat is 50g/m2-500g/m2.

3.Width can reach 110 inches.

4.The main usage is boating, wind blades and sport goods. -

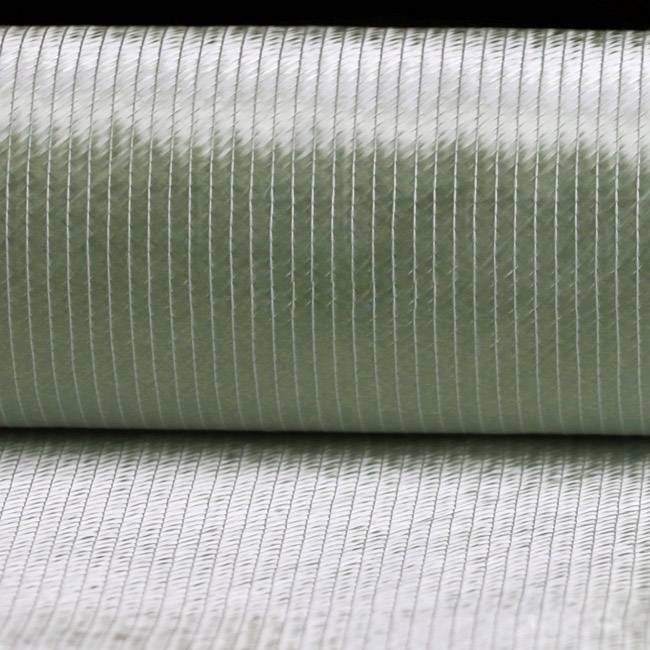

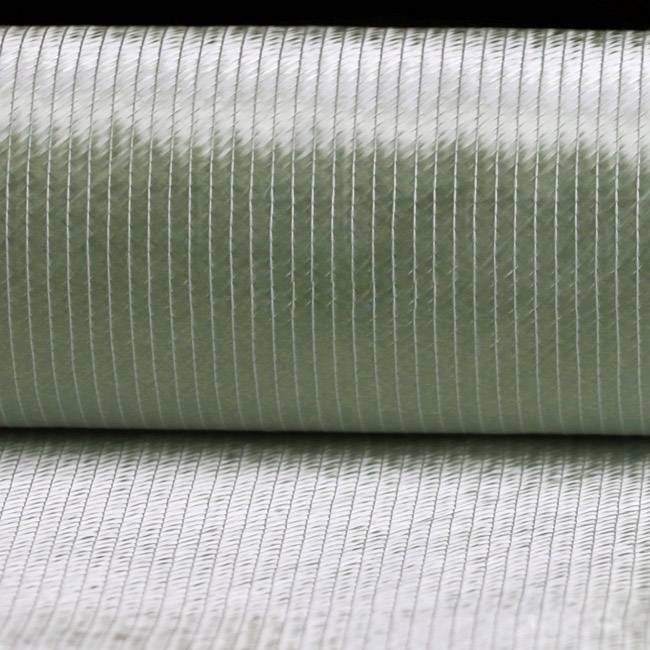

Unidirectional Mat

1.0 degree unidirectional mat and 90 degree unidirectional mat.

2.The density of 0 unidirectional mats is 300g/m2-900g/m2 and the density of 90 unidirectional mats is 150g/m2-1200g/m2.

3.It is mainly used in making tubes and blades of wind power turbines. -

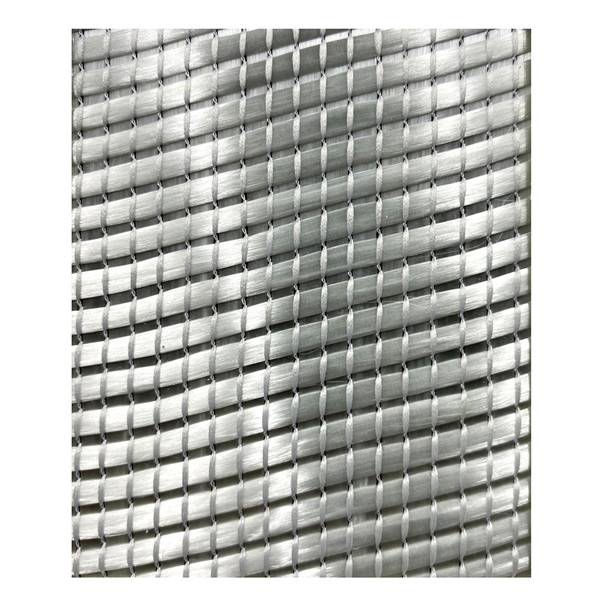

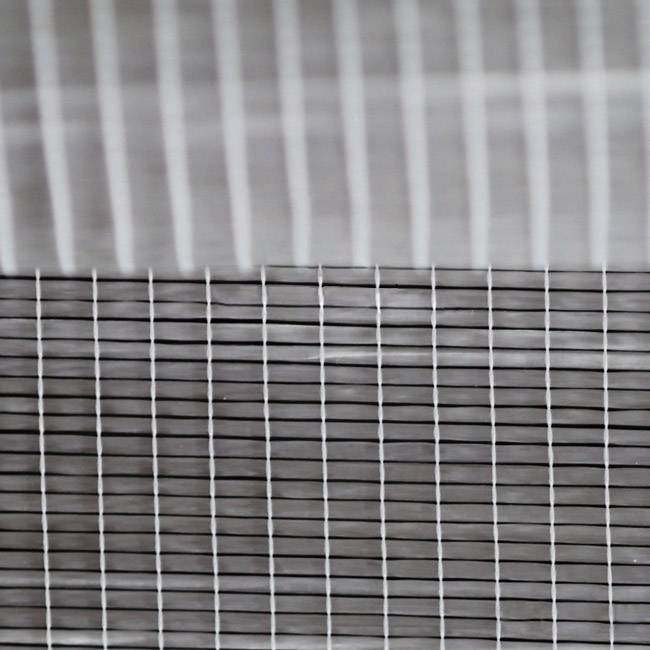

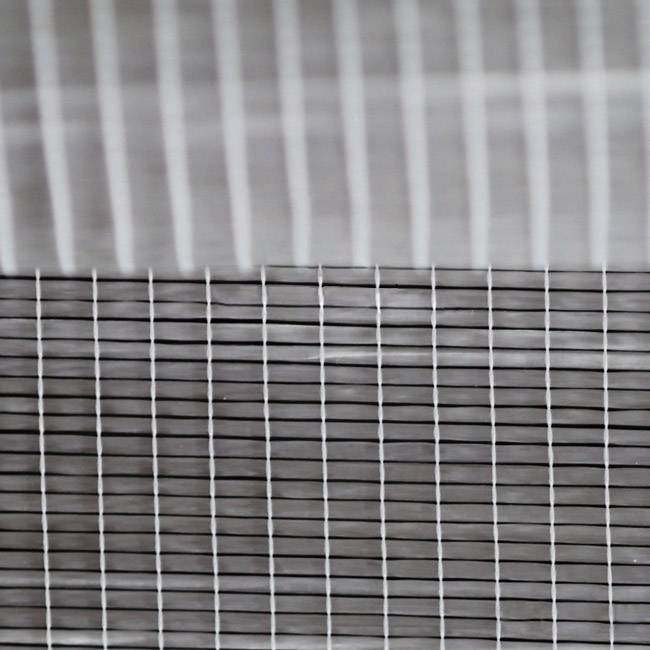

Biaxial Fabric 0°90°

1.Two layers of roving(550g/㎡-1250g/㎡)are aligned at +0°/90°

2.With or without a layer of chopped strands(0g/㎡-500g/㎡)

3.Used in boat manufacturing and automotive parts.