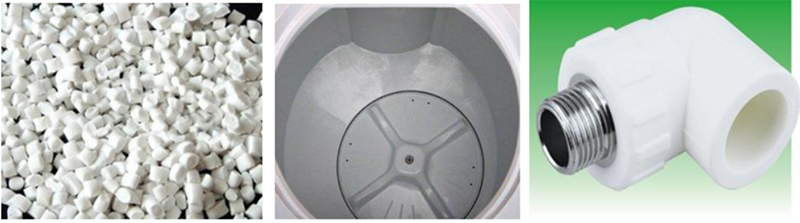

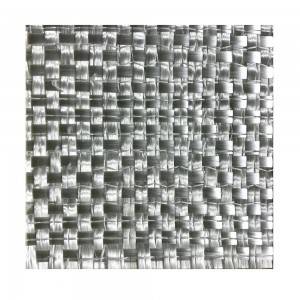

Reinforced pp Fiberglass Chopped Strands

Product Features:

The fiber surface is coated with a special silane type sizing agent and chopped into ECR fiberglass chopped strands Good compatibility with PP and PE, excellent enhancement performance Has excellent clustering, antistatic, low hairiness, high fluidity The product is suitable for extrusion and injection process, and is used in the automotive industry, rail transit, household appliances and daily necessities, etc.

Product List

| Product No. | Chop Length,mm | Resin Compatibility | Features |

| BH-TH01A | 3,4.5 | PA6/PA66/PA46 | Standard product |

| BH-TH02A | 3,4.5 | PP/PE | Standard product, good color |

| BH-TH03 | 3,4.5 | PC | Standard product, excellent mechanical properties, good color |

| BH-TH04H | 3,4.5 | PC | Super high impact properties, glass content below 15% by weight |

| BH-TH05 | 3,4.5 | POM | Standard product |

| BH-TH02H | 3,4.5 | PP/PE | Excellent detergent resistance |

| BH-TH06H | 3,4.5 | PA6/PA66/PA46/HTN/PPA | Excellent glycol resistance and high temperature resistance and fatigue resistance |

| BH-TH07A | 3,4.5 | PBT/PET/ABS/AS | Standard product |

| BH-TH08 | 3,4.5 | PPS/LCP | Excellent hydrolysis resistance and low quantity of flue gas |

Technical Parameters

| Filament Diameter (%) | Moisture Content (%) | LOI Content (%) | Chop length (mm) |

| ISO1888 | ISO3344 | ISO1887 | Q/BH J0361 |

| ±10 | ≤0.10 | 0.50±0.15 | ±1.0 |

Storage

Unless otherwise specified, the fiberglass products should be in dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Packaging

he product can be packed in bulk bags, heavy-duty box and composite plastic woven bags;

For example:

Bulk bags can hold 500kg-1000kg each;

Cardboard boxes and composite plastic woven bags can hold 15kg-25kg each.