PTFE Coated Fabric

Product Introduction

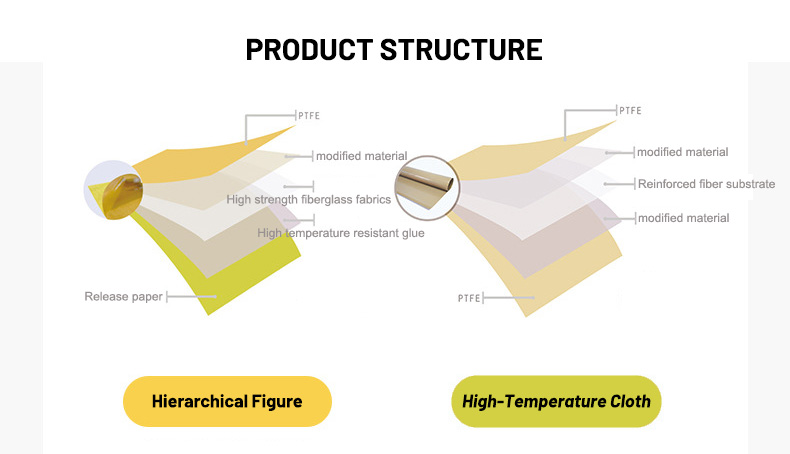

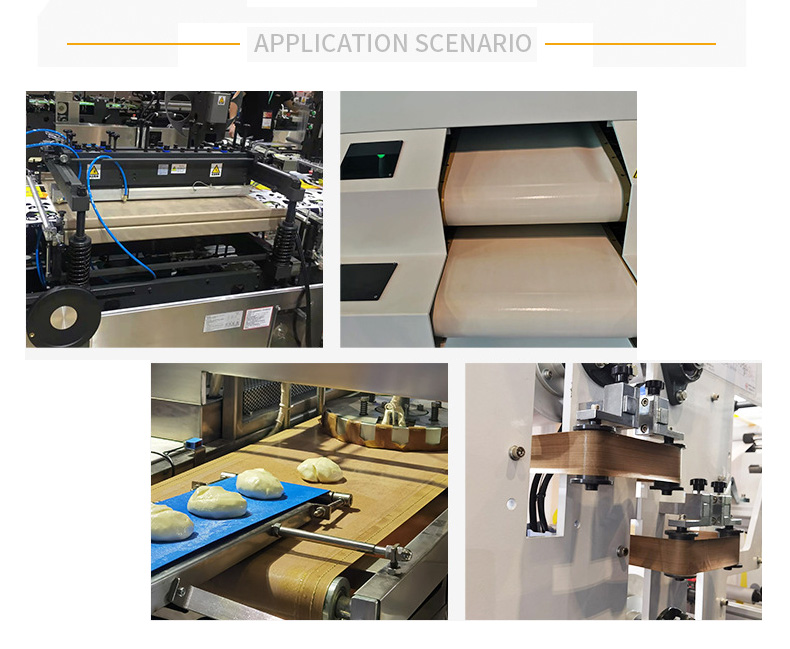

PTFE coated fabric is manufactured by im-pregnating and sintering PTFE onto industrial textiles comprising fiberglass fabrics. We subse -quently process the PTFE coated fabric to produce end products for a diverse range of industries, such as aerospace,automotive,electrical, energy, flooring packaging,and textile manufacturing, among others.

Product Specification

|

Model |

Color |

Width (mm) |

Thickness (mm) |

Areal weight |

PTFE Content (%) |

Tensile Strength (N/5CM) |

Remark |

|

BH9008A |

White |

1250 |

0.075 |

150 |

67 |

550/500 |

|

|

BH9008AJ |

Brown |

1250 |

0.075 |

150 |

67 |

630/600 |

|

|

BH9008J |

brown |

1250 |

0.065 |

70 |

30 |

520/500 |

Permeability |

|

BH9008BJ |

Black |

1250 |

0.08 |

170 |

71 |

550/500 |

Anti-static |

|

BH9008B |

Black |

1250 |

0.08 |

165 |

70 |

550/500 |

|

|

BH9010T |

White |

1250 |

0.1 |

130 |

20 |

800/800 |

Permeability |

|

BH9010G |

White |

1250 |

0.11 |

220 |

53 |

1000/900 |

Rough |

|

BH9011A |

White |

1250 |

0.11 |

220 |

53 |

1000/900 |

|

|

BH9011AJ |

Brown |

1250 |

0.11 |

220 |

53 |

1000/900 |

|

|

BH9012AJ |

Brown |

1250 |

0.12 |

240 |

57 |

1000/900 |

|

|

BH9013A |

White |

1250 |

0.13 |

260 |

60 |

1000/900 |

|

|

BH9013AJ |

Brown |

1250 |

0.13 |

260 |

60 |

1200/1100 |

|

|

BH9013BJ |

Black |

1250 |

0.125 |

240 |

57 |

800/800 |

Anti-static |

|

BH9013B |

Black |

1250 |

0.125 |

250 |

58 |

800/800 |

|

|

BH9015AJ |

Brown |

1250 |

0.15 |

310 |

66 |

1200/1100 |

|

|

BH9018AJ |

Brown |

1250 |

0.18 |

370 |

57 |

1800/1600 |

|

|

BH9020AJ |

Brown |

1250 |

0.2 |

410 |

61 |

1800/1600 |

|

|

BH9023AJ |

Brown |

2800 |

0.23 |

490 |

59 |

2200/1900 |

|

|

BH9025A |

White |

2800 |

0.25 |

500 |

60 |

1400/1100 |

|

|

BH9025AJ |

Brown |

2800 |

0.25 |

530 |

62 |

2500/1900 |

|

|

BH9025BJ |

Black |

2800 |

0.23 |

500 |

60 |

1400/1100 |

Anti-static |

|

BH9025B |

Black |

2800 |

0.23 |

500 |

60 |

1400/1100 |

|

|

BH9030AJ |

Brown |

2800 |

0.3 |

620 |

53 |

2500/2000 |

|

|

BH9030BJ |

Black |

2800 |

0.3 |

610 |

52 |

2100/1800 |

|

|

BH9030B |

Black |

2800 |

0.3 |

580 |

49 |

2100/1800 |

|

|

BH9035BJ |

Black |

2800 |

0.35 |

660 |

62 |

1800/1500 |

Anti-static |

|

BH9035B |

Black |

2800 |

0.35 |

660 |

62 |

1800/1500 |

|

|

BH9035AJ |

Brown |

2800 |

0.35 |

680 |

63 |

2700/2000 |

|

|

BH9035AJ-M |

White |

2800 |

0.36 |

620 |

59 |

2500/1800 |

Ond side smooth,another side rough |

|

BH9038BJ |

Black |

2800 |

0.38 |

720 |

65 |

2500/1600 |

Anti-static |

|

BH9040A |

White |

2800 |

0.4 |

770 |

57 |

2750/2150 |

|

|

BH9040Hs |

Gray |

1600 |

0.4 |

540 |

25 |

3500/2500 |

Single side |

|

BH9050HD |

Gray |

1600 |

0.48 |

620 |

45 |

3250/2200 |

Double side |

|

BH9055A |

White |

2800 |

0.53 |

990 |

46 |

38003500 |

|

|

BH9065A |

Brown |

2800 |

0.65 |

1150 |

50 |

4500/4000 |

|

|

BH9080A |

White |

2800 |

0.85 |

1550 |

55 |

5200/5000 |

|

|

BH9090A |

White |

2800 |

0.9 |

1600 |

52 |

65005000 |

|

|

BH9100A |

White |

2800 |

1.05 |

1750 |

55 |

6600/6000 |

Product Features

1.Climate resistance: can be used for a long time in a wide range of temperatures from -60 ℃ to 300 ℃, in the 300 ℃ high temperature for 200 days for aging test, not only the strength will not be reduced and the weight will not be reduced. Under -180 ℃ ultra-low temperature does not aging cracking, and can maintain the original softness, it can be in 360 ℃ ultra-high temperature working 120 hours without aging, cracking, good softness.

2.Non-adhesion: paste, adhesive resins, organic coatings and almost all sticky substances, can be easily removed from the surface.

3.Mechanical properties: the surface can withstand a compression load of 200Kg/cm2 after the basic will not be deformed, lack of volume. Low friction coefficient, excellent dimensional stability, tensile elongation ≤ 5%.

4.Electrical insulation: electrical insulation, dielectric constant 2.6, dielectric loss tangent below 0.0025.

5.Corrosion resistance: can be resistant to corrosion of almost all pharmaceutical products, in the strong acid, strong alkali conditions, not aging and deformation

6.Low coefficient of friction (0.05-0.1), is a better choice of oil-free self-lubrication

7.Resistant to microwave, high frequency, purple and infrared rays.