-

E-glass Stitched Chopped Strand Mat

1.Areal weight (450g/m2-900g/m2) made by chopping continuous strands into chopped strands and stitching together.

2.Maximum width of 110 inches.

3.Can be used in manufacturing boat manufacturing tubes. -

Chopped Strands for Thermoplastics

1.Based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP.

2.Widely use for automotive,home appliance, valves, pump housings, chemical corrosion resistance and sports apparatus. -

E-glass Assembled Roving For GMT

1.Coated with a silane-based sizing compatible with PP resin.

2.Used in the GMT needed mat process.

3.The end-use applications:automotive acoustical inserts,building & construction,chemical,packing and transportation low density components. -

E-glass Assembled Roving For Chopping

1.Coated with special silane-based sizing,compatible with UP and VE, delivering relatively high resin absorbability and excellent choppability,

2.Final composite products deliver superior water resistance and excellent chemical corrosion resistance.

3.Typically used to manufacture FRP pipes. -

E-glass Assembled Roving For Centrifugal Casting

1.Coated with a silane-based sizing, compatible with unsaturated polyester resins.

2.It is a proprietary sizing formulation applied using a special manufacturing process which together result in an extremely fast wet-out speed and very low resin demand.

3.Enable maximum filler loading and therefore the lowst cost pipe manufacture.

4.Mainly used to manufacture Centrifugal Casting pipes of various specifications

and some special Spay-up processes. -

E-glass Assembled Roving For Thermoplastics

1.Coated with a silane-based sizing compatible with multiple resin systems

such as PP、AS/ABS,especially reinforcing PA for good hydrolysis resistant.

2.Typically designed for twin-screw extrusion process to manufacture thermoplastic granules.

3.Key applications include railway track fastening pieces、automotive parts,elactrical & electronic applications. -

Direct Roving For Weaving

1.It is compatible with unsaturated polyester, vinyl ester and epoxy resins.

2.Its excellent weaving property makes it suited for fiberglass product, such as roving cloth, combination mats, stitched mat, multi-axial fabric, geotextiles, molded grating.

3.The end-use products are widely used in building & construction, wind power and yacht applications. -

Direct Roving For Pultrusion

1.It is coated with a silane-based sizing compatible with unsaturated polyester, vinyl ester and epoxy resin.

2.It is designed for filament winding, pultrusion, and weaving applications.

3.It is suitable for use in pipes,pressure vessels, gratings, and profiles,

and the woven roving converted from it is used in boats and chemical storage tanks -

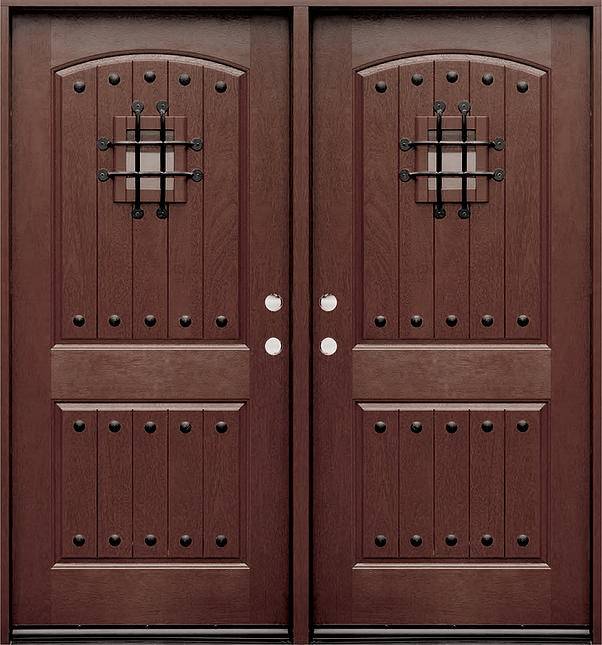

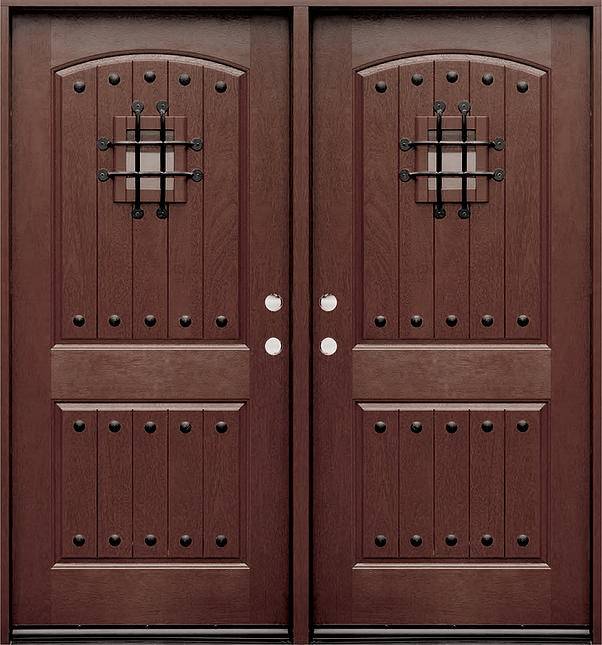

FRP Door

1.new generation environmental-friendly and energy-efficiency door, more excellent than previous ones of wood, steel, aluminum and plastic. It is composed of high strength SMC skin, polyurethane foam core and plywood frame.

2.Features:

energy-saving, eco-friendly,

heat insulation, high strength,

light weight, anti-corrosion,

good weatherability, dimensional stability,

long life span, varied colors etc. -

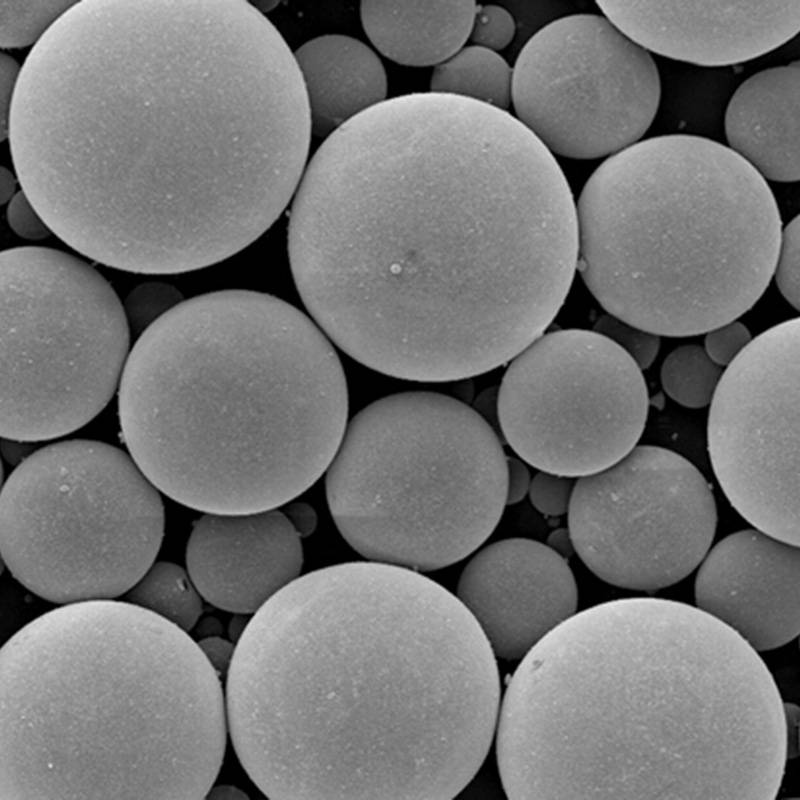

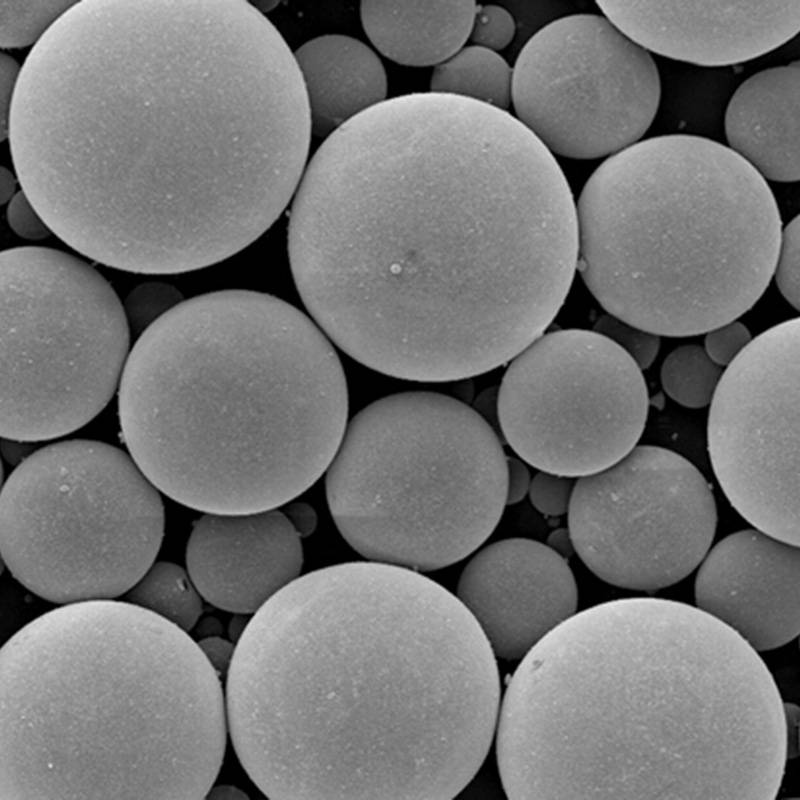

Hollow Glass Microspheres

1.Ultra-light inorganic non-metallic powder with hollow “ball-bearing” shapes,

2.New type of high performance lightweight material and widely applied -

Milled Fibeglass

1.Milled Glass Fibers is made from E-glass and are available with well-defined average fiber lengths between 50-210 microns

2.They are specially designed for reinforcement of thermosetting resins, thermoplastic resins and also for painting applications

3.The products can be coated or non-coated to improve the composite’s mechanical properties, abrasion properties and surface appearance. -

S-Glass Fiber high strength

1.Compared with E Glass fiber,

30-40% higher tensile strength,

16-20% higher modulus of elasticity.

10 folds higher fatigue resistance,

100-150 degree higher temperature endure,

2. Excellent impact resistance because of high elongation to break, high ageing & corrosion resistance, quick resin wet-out properties.