-

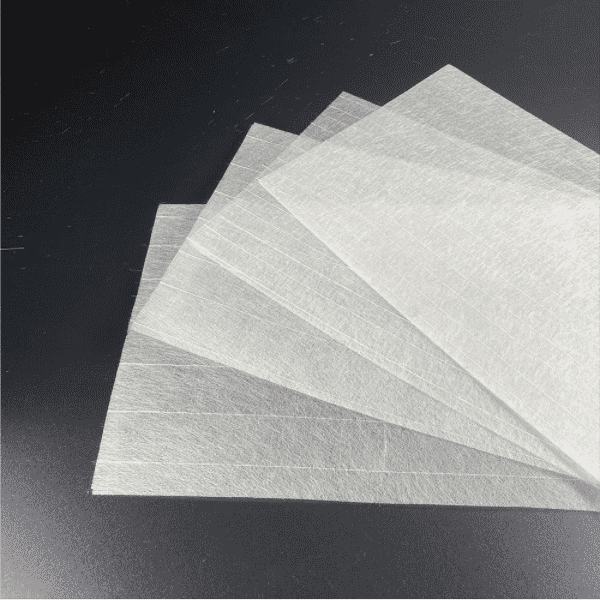

Fiberglass Wall Covering Tissue Mat

1.A environment-friendly product made of chopped fiber glass by wet process

2.Mainly applied for the surface layer and the inner layer of wall and ceiling

.Fire-retardancy

.Anti-corrosion

.Shock-resistance

.Anti-corrugation

.Crack-resistance

.Water-resistance

.Air-permeability

3.Widely used in public entertainment place, conference hall, star-hotel, restaurant, cinema, hospital, school, office building and resident house.. -

Cenosphere (Microsphere)

1.Fly ash hollow ball that can float on the water.

2.It is grayish white, with thin and hollow walls, light weight, bulk weight 250-450kg/m3,and particle size about 0.1 mm.

3.Widely used in the production of light weight castable and oil drilling and in various industries. -

BMC

1.Secially designed for reinforcing unsaturated polyester, epoxy resin and phenolic resins.

2.Widely used in transportation, construction, electronics,chemical industry and light industry. Such as the automotive parts, insulator and switch boxes. -

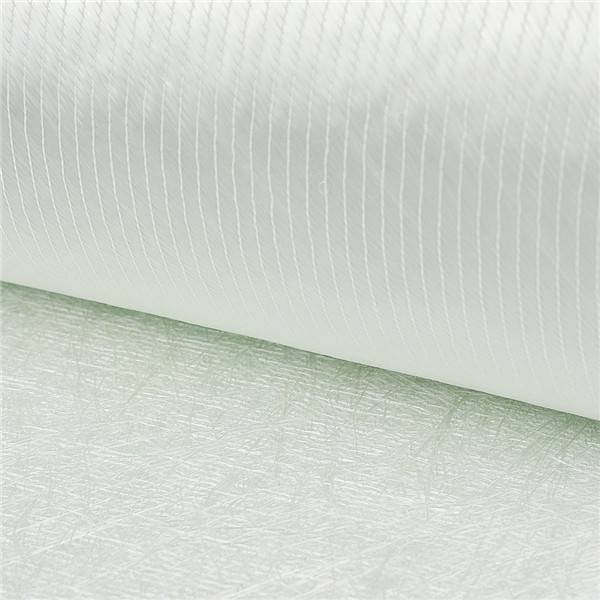

Fiberglass Roofing Tissue Mat

1.Mainly used as excellent substrates for waterproof roofing materials.

2.High tensile strength, corrosion resistance, easy soakage by bitumen, and so on.

3.Areal weight from 40gram/m2 to 100 gram /m2, and the space between yarns is 15mm or 30mm (68 TEX) -

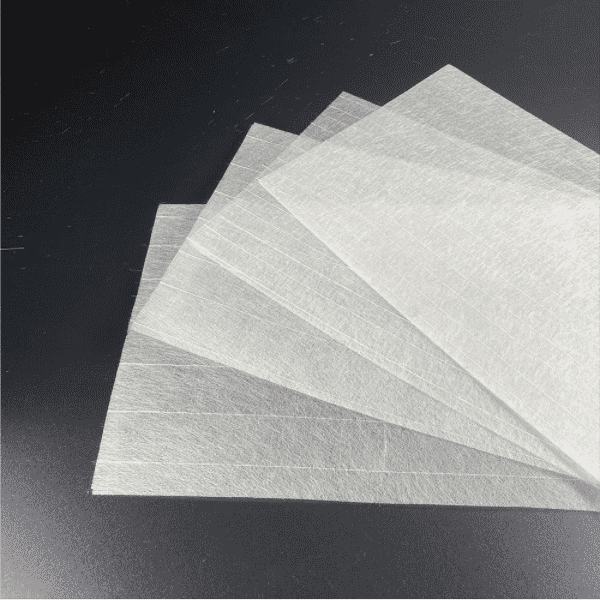

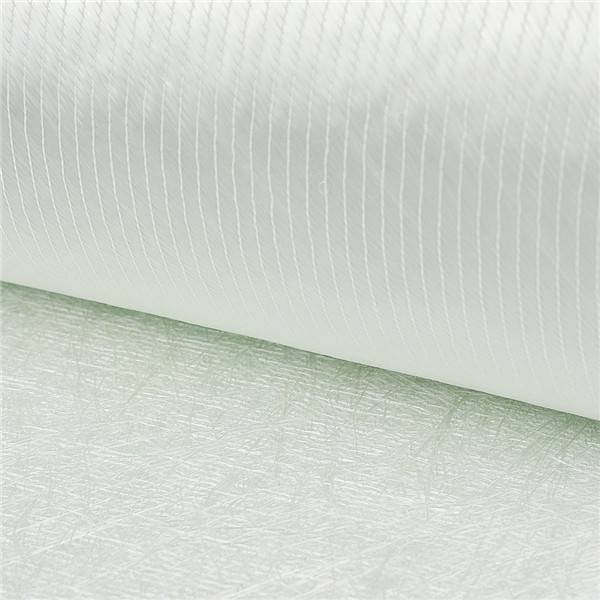

Fiberglass Surface Tissue Mat

1.Mainly used as the surface layers of FRP products.

2.Uniform fiber dispersion, smooth surface, soft hand-feeling, lowbinder content, fast resin impregnation and good mould obedience.

3.Filament winding type CBM series and hand lay-up type SBM series -

Triaxial Fabric Longitudinal Triaxial(0°+45°-45°)

1.Three layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.Used in blades of wind power turbines, boat manufacturing and sports advices. -

E-glass Assembled Panel Roving

1.For continuous panel molding process is coated with a silane-based sizing compatible with unsaturated polyester.

2.Delivers light weight, high strength and high impact strength,

and is designed to manufacture transparent panels and mats for tansparent panels. -

E-glass Assembled Roving For Spray up

1.Good runnability for spraying operation,

.Moderate wet-out speed,

.Easy roll-out,

.Easyremoval of bubbles,

.No spring back in sharp angles,

.Excellent mechanical properties

2.Hydrolytic resistance in parts,suitable for high-speed spray-up process with robots -

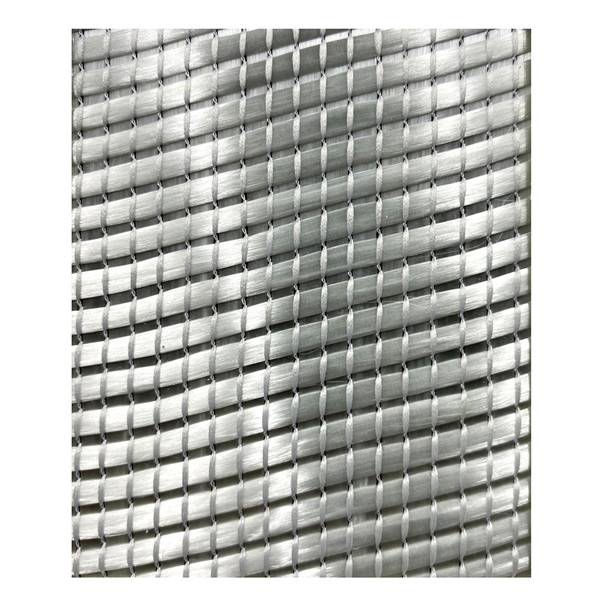

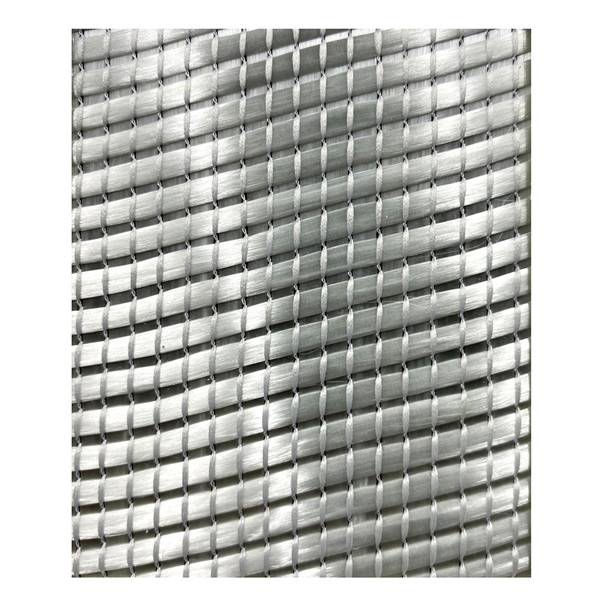

Biaxial Fabric +45°-45°

1.Two layers of rovings(450g/㎡-850g/㎡)are aligned at +45°/-45°

2.With or without a layer of chopped strands(0g/㎡-500g/㎡).

3.Maximum width of 100 inches.

4.Used in boat manufacturing. -

E-glass Assembled Roving For Filament Winding

1.Specially designed for FRP filament winding process, compatible with unsaturated polyester.

2.Its final composite product delivers excellent mechanical property,

3.Mainly used to manufacture storage vessels and pipes in petroleum, chemical and mining industries. -

E-glass Assembled Roving For SMC

1.Designed for class A surface and structural SMC process.

2.Coated with a high performance compound sizing compatible with unsaturated polyester resin

and vinyl ester resin.

3.Compared with traditional SMC roving,It can deliver high glass content in SMC sheets and has good wet-out and excellent surface property .

4.Used in automotive parts, doors ,chairs, bathtubs, and water tanks and sporrts apparatus -

Direct Roving For LFT

1.It is coated with a silane-based sizing compatible with PA, PBT, PET, PP, ABS, PPS and POM resins.

2.Widely used in industries of automotive, electromechanical, home appliance, building & construction, electronic & electrical, and aerospace