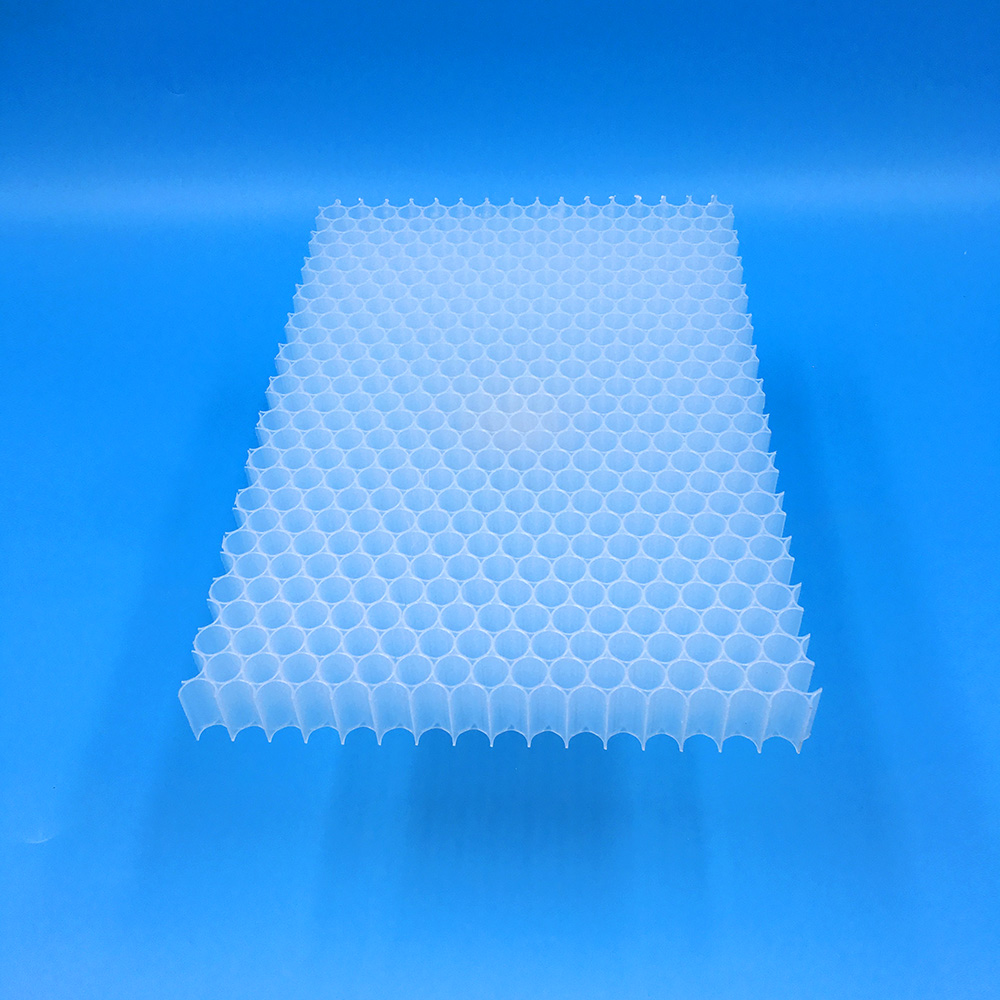

PP Honeycomb Core Material

Product Description

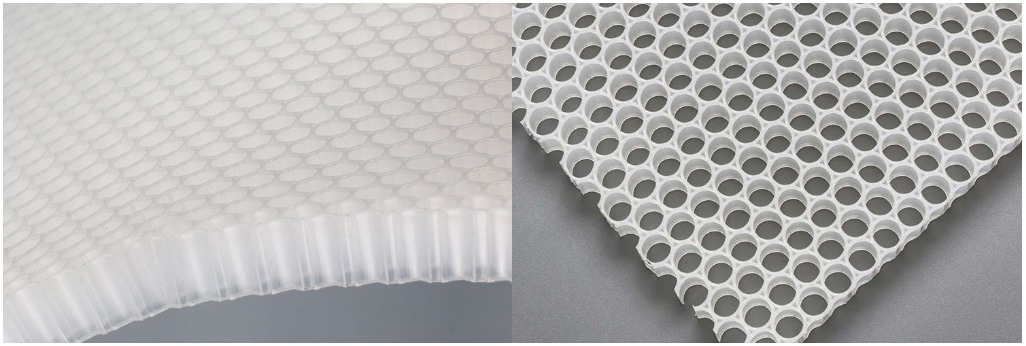

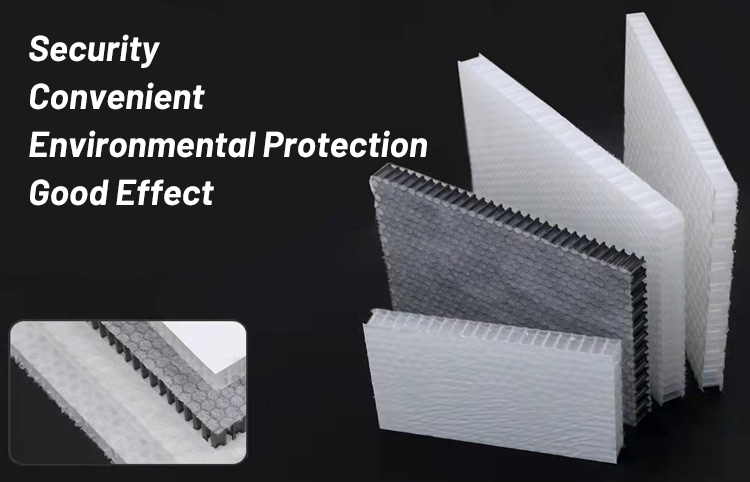

Thermoplastic honeycomb core is a new type of structural material processed from PP/PC/PET and other materials according to the bionic principle of honeycomb. It has the characteristics of light weight and high strength, green environmental protection, waterproof and moisture-proof and corrosion-resistant, etc. It can be compounded with different surface materials (such as wood grain plate, aluminum plate, stainless steel plate, marble plate, rubber plate, etc.). It can replace traditional materials in large scale and is widely used in vans, high-speed railways, aerospace, yachts, homes, mobile buildings and other fields.

Product Features

1. Light weight and high strength (high specific stiffness)

- Excellent compressive strength

- Good shear strength

- Light weight and low density

2. Green environmental protection

- Energy saving

- 100% recyclable

- No VOC in processing

- No odor and formaldehyde in the application of honeycomb products

3. Waterproof and moisture-proof

- It has excellent waterproof and moistureproof performance, and can be better applied in the field of water construction.

4. Good corrosion resistance

- Excellent corrosion resistance, can resist the erosion of chemical products, seawater and so on.

5. Sound insulation

- Honeycomb panel can effectively reduce damping vibration and absorb noise.

6. Energy absorption

- The special honeycomb structure has excellent energy absorption properties. It can effectively absorb energy, resist impact and share load.

Product Application

Plastic honeycomb core is mainly used in rail transportation, ships (especially yachts, speedboats), aerospace, marinas, pontoon bridges, van-type cargo compartments, chemical storage tanks, construction, glass fiber reinforced plastic, high-grade housing decoration, high-grade movable rooms, sports protection products, body protection products and many other fields.