PEEK 100% Pure PEEK Pellet

Product Description

Polyether ether ketone (PEEK) is in the main chain structure contains a ketone bond and two ether bond repeating unit composed of polymers, is a special polymer materials. With high temperature resistance, chemical corrosion resistance and other physical and chemical properties, is a class of semi-crystalline polymer materials, can be used as high-temperature-resistant structural materials and electrical insulation materials, and can be composite with glass fibers or carbon fibers to prepare reinforcing materials.

Product Parameters

|

Fluidity

|

3600 Series

|

5600 Series

|

7600 Series

|

|

Unfilled PEEK powder

|

3600P

|

5600P

|

7600P

|

|

Unfilled PEEK pellet

|

3600G

|

5600G

|

7600G

|

|

Glass fiber filed PEEK pellet

|

3600GF30

|

5600GF30

|

7600GF30

|

|

Carbon fiber flled PEEK pellet

|

3600CF30

|

5600CF30

|

7600CF30

|

|

HPV PEEK pellet

|

3600LF30

|

5600LF30

|

7600LF30

|

|

Application

|

Good fluidity,suitable forthin-walled PEEK products

|

Medium fluidity, suitablefor general PEEK parts

|

Low liquidity, suitable forPEEK parts with high machnical requirement

|

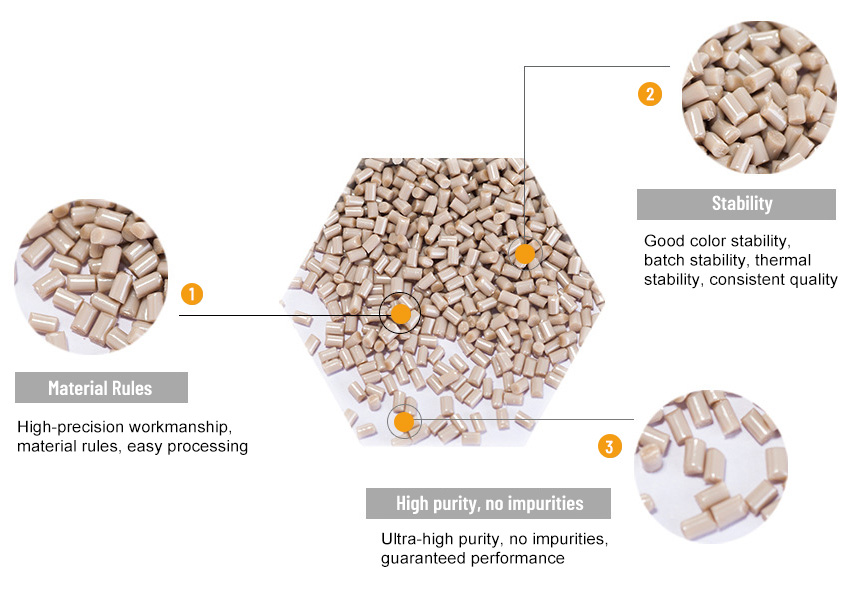

Main Characteristics

① Heat-resistant properties

PEEK resin is a semi-crystalline polymer. Its glass transition temperature Tg = 143 ℃, melting point Tm = 334 ℃.

Mechanical Properties

The tensile strength of PEEK resin at room temperature is 100MPa, 175MPa after 30% GF reinforcement, 260Mpa after 30% CF reinforcement; the bending strength of pure resin is 165MPa, 265MPa after 30% GF reinforcement, 380MPa after 30% CF reinforcement.

③ Impact resistance

The impact resistance of PEEK pure resin is one of the best varieties of special engineering plastics, and its unnotched impact can reach more than 200Kg-cm/cm.

④ Flame retardant

PEEK resin has its own flame retardant, without adding any flame retardant can reach the highest flame retardant grade (UL94V-O).

⑤ Chemical Resistance

PEEK resin has good chemical resistance.

⑥ Water Resistance

The water absorption of PEEK resin is very small, the saturated water absorption at 23 ℃ is only 0.4%, and good hot water resistance, can be used for a long time in 200 ℃ of high-pressure hot water and steam.

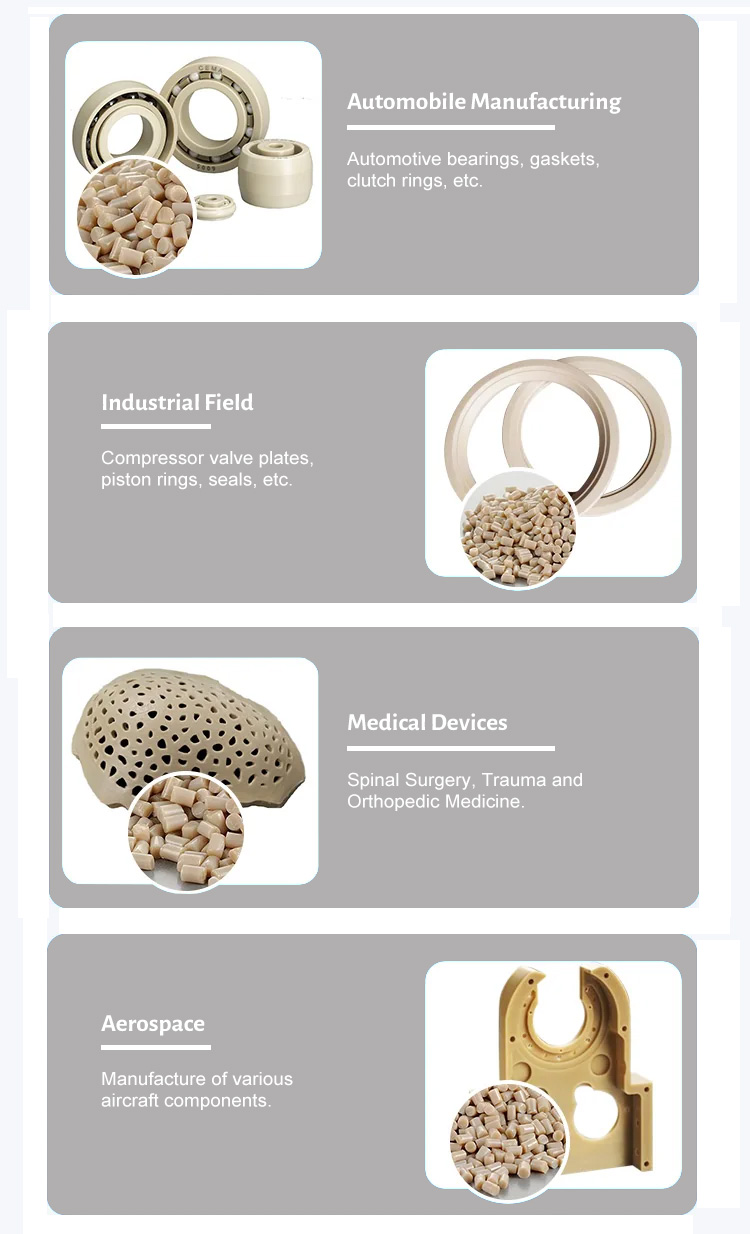

Product Application

Because of the excellent comprehensive performance of polyether ether ketone, in many special areas can replace the metal, ceramics and other traditional materials. The plastic’s high temperature resistance, self-lubrication, wear resistance and fatigue resistance make it one of the hottest high-performance engineering plastics, which is mainly used in aerospace, automotive industry, electrical and electronic, and medical equipment and other fields.