OEM Customized Chopped Glass Fiber - 3D FRP Sandwich Panel – Beihai Fiberglass

OEM Customized Chopped Glass Fiber - 3D FRP Sandwich Panel – Beihai Fiberglass Detail:

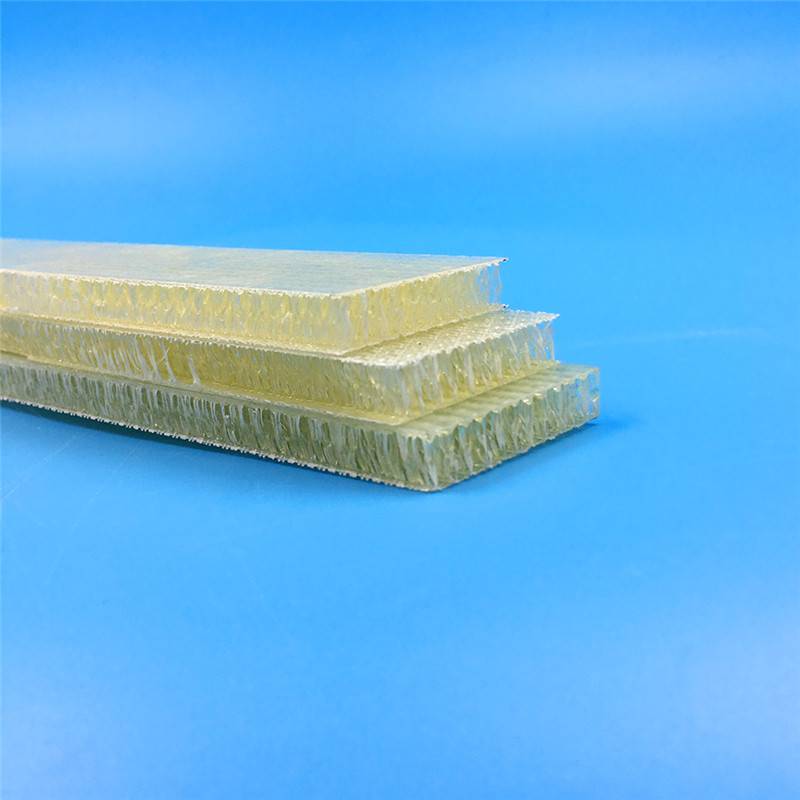

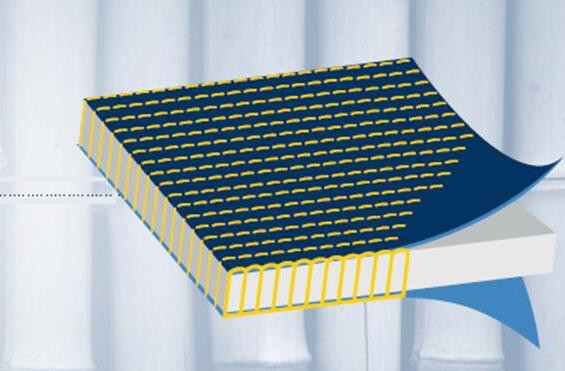

3D FRP stiched foam sandwich panel is new process.New process can produce high strength and density of homogeneous composite panel. Sew highdensity PU plate into the special 3 d fabric, through the RTM (vacuum moldig process).

Advantage

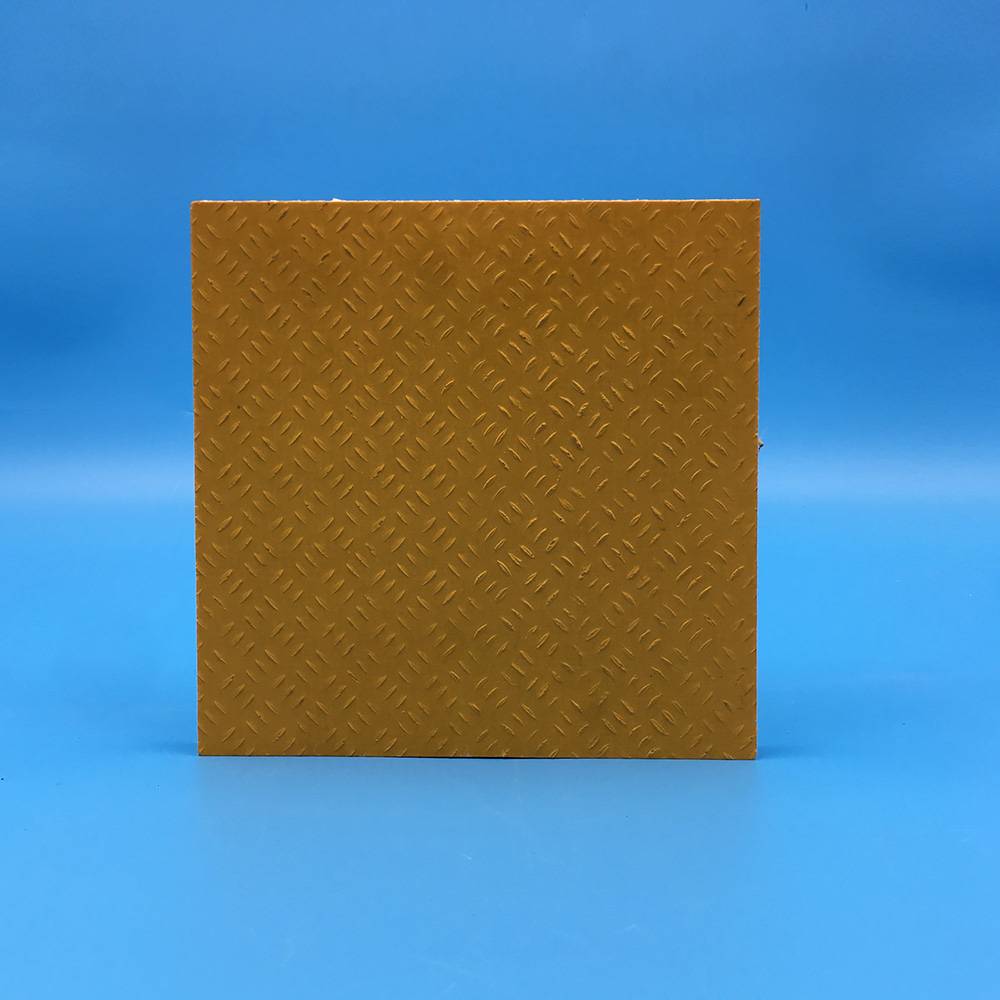

●Fully Fashioned.

●Panel face is very beautiful,

●High strength.

●One-time finishing, slove the problem of traditional sandwich panel foaming.

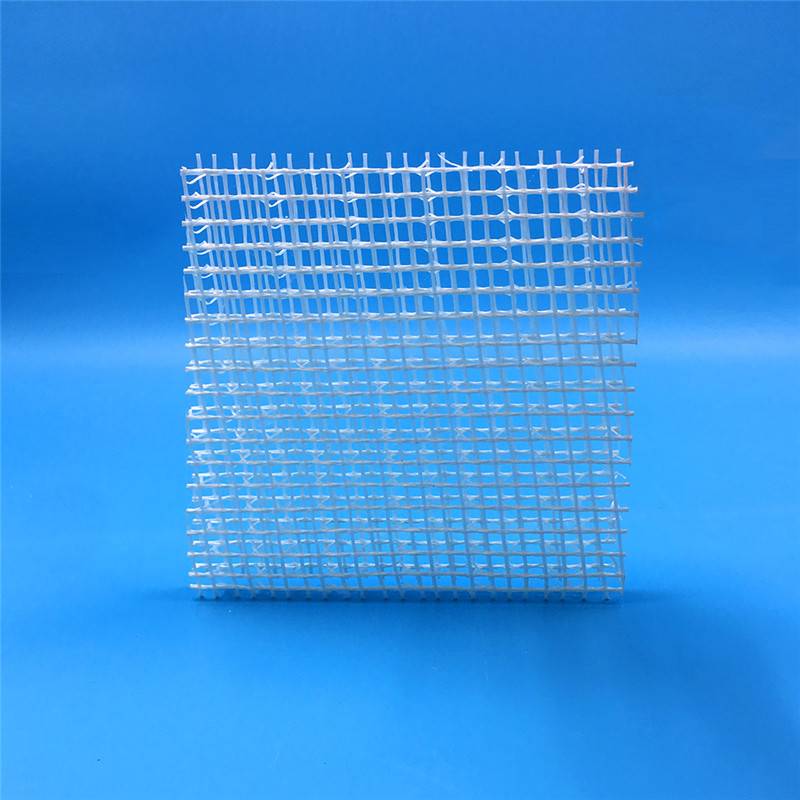

Structure chart

If it is molded in ordinary 3D cloth and then filled with PU foam, the foam will not be uniform, and the density will not be consistent. The strength of the panel will be very low.

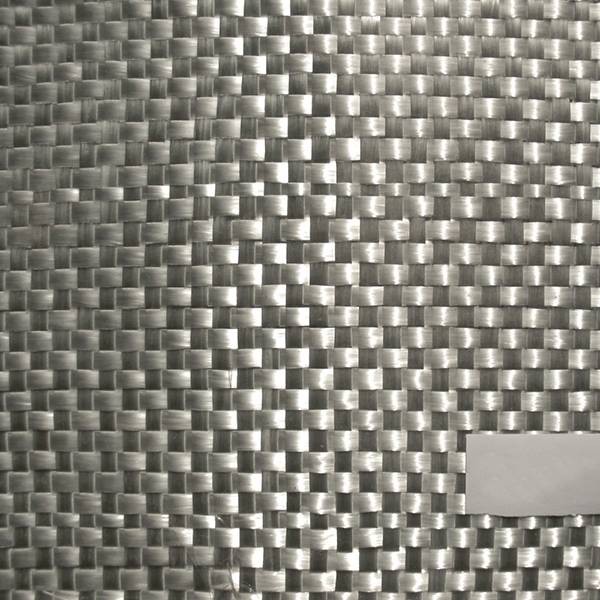

The largest width is 1500mm, you can choose the different foam, such as PU,PVC and so on. The PVC foam strength is higher than PU, the price is also higher. The PU foam thinnest is 5mm,the PVC foam thinnest is 3mm.The normal size is 1200x2400mm, for the normal panel choose the PU foam(density 40kg/m3) +two sides combo mat or woven roving, the total thickness is 20mm.

Application

Benefits of RTM

| The benefits of RTM | What does it bring you? |

| Product surface will be fully defined during pressing | Low finishing costs and beautiful quality |

| Large mould freedom and high fibre-volume(up to 60%) | Ultimate mechanic properties |

| Constant Reproducible | Low dropout rate and suited for advanced applications |

| Continuous innovative industrialisation | Cost savings, higher tool capacity |

| Closed mould technique | Barely any emissions and operator friendly |

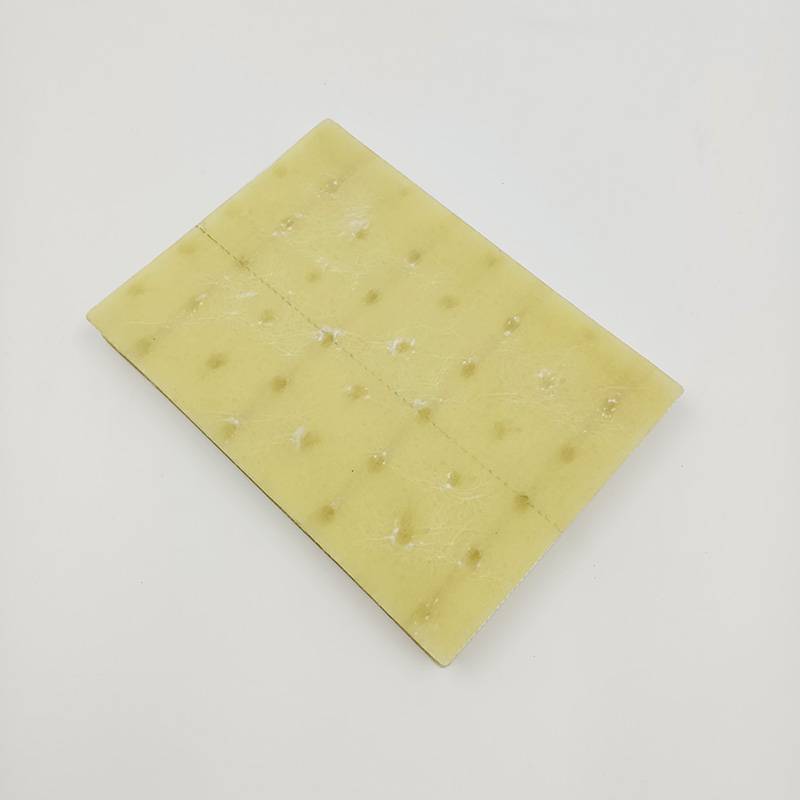

Product detail pictures:

Related Product Guide:

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for OEM Customized Chopped Glass Fiber - 3D FRP Sandwich Panel – Beihai Fiberglass , The product will supply to all over the world, such as: Greenland, United Arab Emirates, Rwanda, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!