Polymer honeycomb, also known as PP honeycomb core material, is a lightweight, multifunctional material that is popular in various industries because of its unique structure and performance. This article aims to explore what polymer honeycomb is, its applications and the benefits it offers.

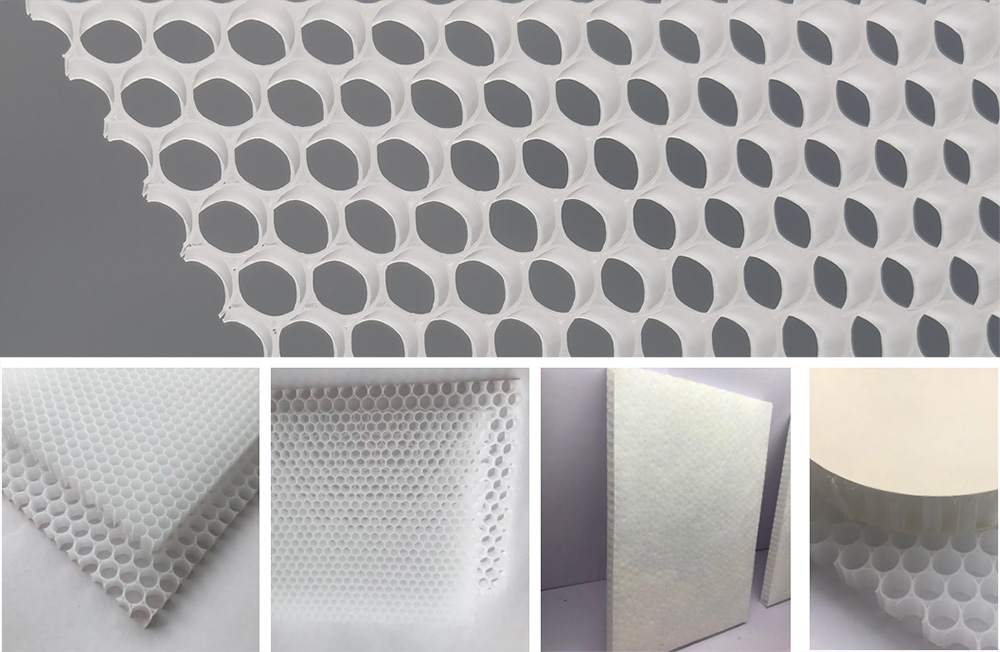

Polymer honeycomb is a composite material composed of a series of hexagonal units made of polypropylene (PP) or other polymer resins. The cells are arranged in a honeycomb structure, giving the material an excellent strength-to-weight ratio and stiffness. The lightweight nature of polymer honeycombs makes them ideal for applications where weight reduction is critical, such as the aerospace, automotive, marine and construction industries.

One of the key properties of polymer honeycomb is its high strength and stiffness, allowing it to withstand heavy loads and impacts while maintaining its structural integrity. This makes it an excellent choice for the core material of sandwich panels, providing reinforcement and support to the outer skin. In addition, honeycomb structures offer excellent energy absorption and impact resistance, making them suitable for applications where protection from dynamic forces and vibrations is required.

The versatility of polymer honeycomb extends to its thermal and acoustic insulation properties. The air-filled cells within the honeycomb structure form an effective barrier against heat transfer, making it an effective choice for insulation in buildings, refrigerated trucks and other temperature-sensitive applications. In addition, the porous structure of polymer honeycomb also contributes to its sound absorption capabilities, making it an ideal material for noise control and insulation in a variety of environments.

In addition to their mechanical and insulating properties, polymer honeycombs are also known for their corrosion resistance and durability. The inertness of polypropylene and other polymer resins used to make honeycomb cores makes them highly resistant to moisture, chemicals and environmental factors, ensuring long-term performance and reliability in harsh conditions. This makes polymer honeycomb an attractive option for applications in marine environments, chemical processing plants, and outdoor structures exposed to corrosive elements.

Overall, polymer honeycombs offer a wide range of benefits, including lightweight construction, high strength, thermal and acoustic insulation, and corrosion resistance, making them a versatile material suitable for a variety of applications. As technology and manufacturing processes continue to advance, the use of polymer honeycombs is expected to expand further, providing innovative solutions to industries seeking lightweight, durable and high-performance materials. Whether in the aerospace, automotive, marine or construction sectors, polymer honeycombs continue to prove their worth as reliable, efficient core materials.

Post time: Mar-28-2024