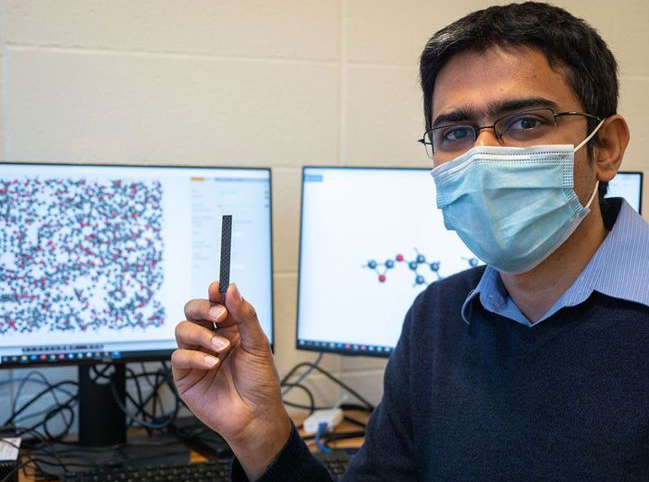

A few days ago, University of Washington professor Aniruddh Vashisth published a paper in the international authoritative journal Carbon, claiming that he had successfully developed a new type of carbon fiber composite material. Unlike traditional CFRP, which cannot be repaired once damaged, new materials can be repaired repeatedly.

While maintaining the mechanical properties of traditional materials, the new CFRP adds a new advantage, that is, it can be repaired repeatedly under the action of heat. Heat can repair any fatigue damage of the material, and can also be used to decompose the material when it needs to be recycled at the end of the service cycle. Since traditional CFRP cannot be recycled, it is important to develop a new material that can be recycled or repaired using thermal energy or radio frequency heating.

Professor Vashisth said that the heat source can indefinitely delay the aging process of the new CFRP. Strictly speaking, this material should be called Carbon Fiber Reinforced Vitrimers (vCFRP, Carbon Fiber Reinforced Vitrimers). Glass polymer (Vitrimers) is a new type of polymer material that combines the advantages of thermoplastic and thermosetting plastics invented by French scientist Professor Ludwik Leibler in 2011. Vitrimers material uses dynamic bond exchange mechanism, which can perform reversible chemical bond exchange in a dynamic manner when heated, and at the same time maintain a cross-linked structure as a whole, so that thermosetting polymers can be self-healing and reprocessed like thermoplastic polymers.

In contrast, the commonly referred to as carbon fiber composite materials are carbon fiber reinforced resin matrix composite materials (CFRP), which can be divided into two types: thermoset or thermoplastic according to the different resin structure. Thermosetting composite materials usually contain epoxy resin, the chemical bonds in which can permanently consolidate the material into one body. Thermoplastic composites contain relatively soft thermoplastic resins that can be melted and reprocessed, but this will inevitably affect the strength and stiffness of the material.

The chemical bonds in vCFRP can be connected, disconnected, and reconnected to obtain a “middle ground” between thermoset and thermoplastic materials. Project researchers believe that Vitrimers can become a substitute for thermosetting resins and avoid the accumulation of thermosetting composites in landfills. Researchers believe that vCFRP will become a major shift from traditional materials to dynamic materials, and will have a series of impacts in terms of full life cycle cost, reliability, safety, and maintenance.

At present, wind turbine blades are one of the areas where CFRP usage is large, and the recovery of blades has always been a problem in this field. After the expiration of the service period, thousands of retired blades were discarded in the landfill in the form of landfill, which caused a huge impact on the environment.

If vCFRP can be used for blade manufacturing, it may be recycled and reused by simple heating. Even if the treated blade cannot be repaired and reused, at least it can be decomposed by heat. The new material transforms the linear life cycle of thermoset composites into a cyclic life cycle, which will be a big step towards sustainable development.

If vCFRP can be used for blade manufacturing, it may be recycled and reused by simple heating. Even if the treated blade cannot be repaired and reused, at least it can be decomposed by heat. The new material transforms the linear life cycle of thermoset composites into a cyclic life cycle, which will be a big step towards sustainable development.

Post time: Nov-09-2021