Recently, AREVO, an American composite additive manufacturing company, completed the construction of the world’s largest continuous carbon fiber composite additive manufacturing plant.

It is reported that the factory is equipped with 70 self-developed Aqua 2 3D printers, which can focus on quickly printing large-size continuous carbon fiber parts. The printing speed is four times faster than its predecessor Aqua1, which is suitable for quickly creating on-demand customized parts. The Aqua 2 system has been used in the production of 3D printed bicycle frames, sports equipment, auto parts, aerospace parts and building structures.

In addition, AREVO recently completed a $25 million round of financing led by Khosla Ventures with participation from venture capital firm Founders Fund.

Sonny Vu, CEO of AREVO said: “After the launch of Aqua 2 last year, we began to focus on the development of mass production and operation systems. Now, a total of 76 production systems are connected via the cloud and run in different locations. We have completed The first stage of industrialization. Arevo is ready for market growth and can meet the production needs of the company itself and B2B customers.”

AREVO’s carbon fiber 3D printing technology

In 2014, AREVO was established in Silicon Valley, USA, and is known for its continuous carbon fiber 3D printing technology. This company initially released FFF/FDM composite material series products, and has since developed advanced 3D printing software and hardware systems.

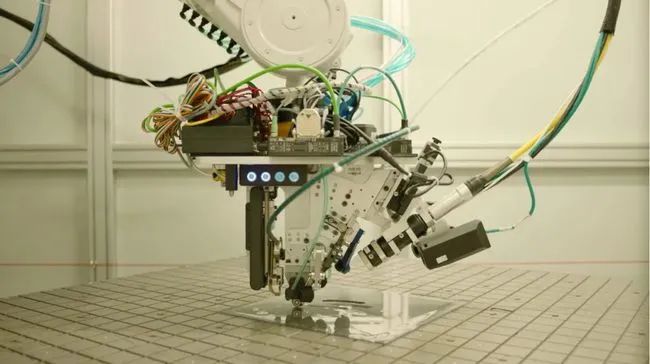

In 2015, AREVO created its scalable robot-based additive manufacturing (RAM) platform to optimize the program through finite element analysis tools to improve the strength and appearance of 3D printed parts. After six years of development, the company’s continuous carbon fiber 3D printing technology has applied for more than 80 patent protections.

Post time: Aug-17-2021