Using carbon fiber composite material structure, the “Neutron” rocket will become the world’s first large-scale carbon fiber composite material launch vehicle.

Based on the previous successful experience in the development of a small launch vehicle “Electron”, Rocket Lab USA, a leading US launch and space system company, has developed a large-scale launch called “Neutron” Rockets, with a payload capacity of 8 tons, can be used for manned spaceflight, large satellite constellation launches, and deep space exploration. The rocket has achieved breakthrough results in design, materials and reusability.

The “Neutron” rocket is a new type of launch vehicle with high reliability, reusability and low cost. Unlike traditional rockets, the “Neutron” rocket will be developed according to the needs of customers. It is estimated that more than 80% of the satellites launched in the next ten years will be satellite constellations, with special deployment requirements. The “Neutron” rocket can specifically meet such special needs. The “Neutron” launch vehicle has made the following technological breakthroughs:

1. The world’s first large-scale launch vehicle using carbon fiber composite materials

The “Neutron” rocket will be the world’s first large-scale launch vehicle using carbon fiber composite materials. The rocket will use a new and special carbon fiber composite material, which is light in weight, high in strength, can withstand the huge heat and impact of launch and reentry, so that the first stage can be used repeatedly. In order to achieve rapid manufacturing, the carbon fiber composite structure of the “Neutron” rocket will be manufactured using an automatic fiber placement (AFP) process, which can produce a carbon fiber composite rocket shell several meters long in a few minutes.

2. The new base structure simplifies the launch and landing process

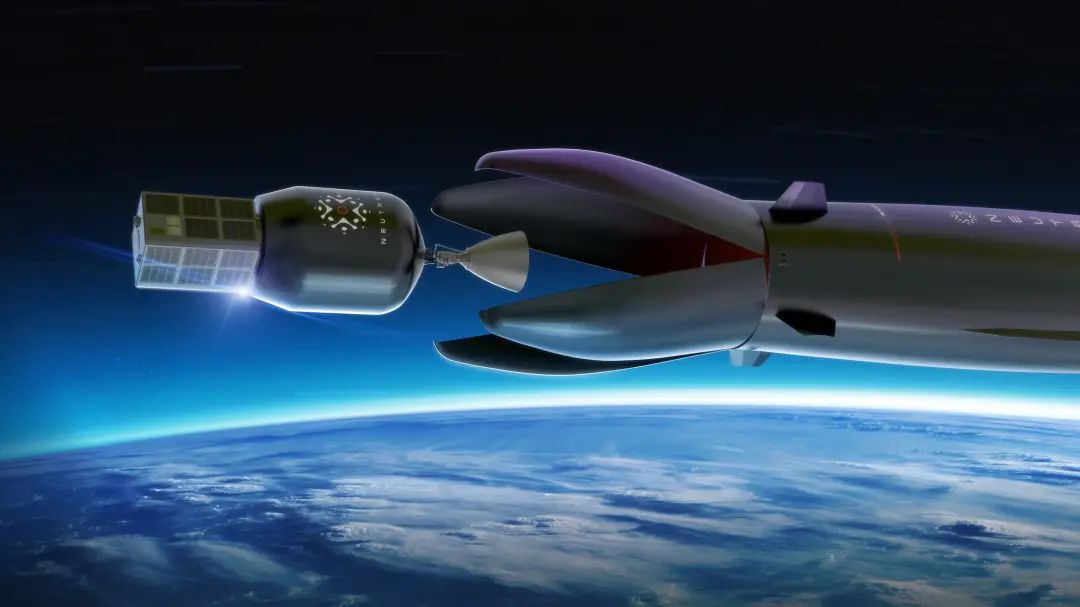

Reusability is the key to frequent and low-cost launches, so from the beginning of the design, the “Neutron” rocket was given the ability to land, recover and launch again. Judging from the shape of the “Neutron” rocket, the tapered design and large, solid base not only simplify the complex structure of the rocket, but also eliminate the need for landing legs and bulky launch site infrastructure. The “Neutron” rocket does not rely on a launch tower, and can launch activities only on its own base. After launching into orbit and releasing the second-stage rocket and its payload, the first-stage rocket will return to the earth and make a soft landing at the launch site.

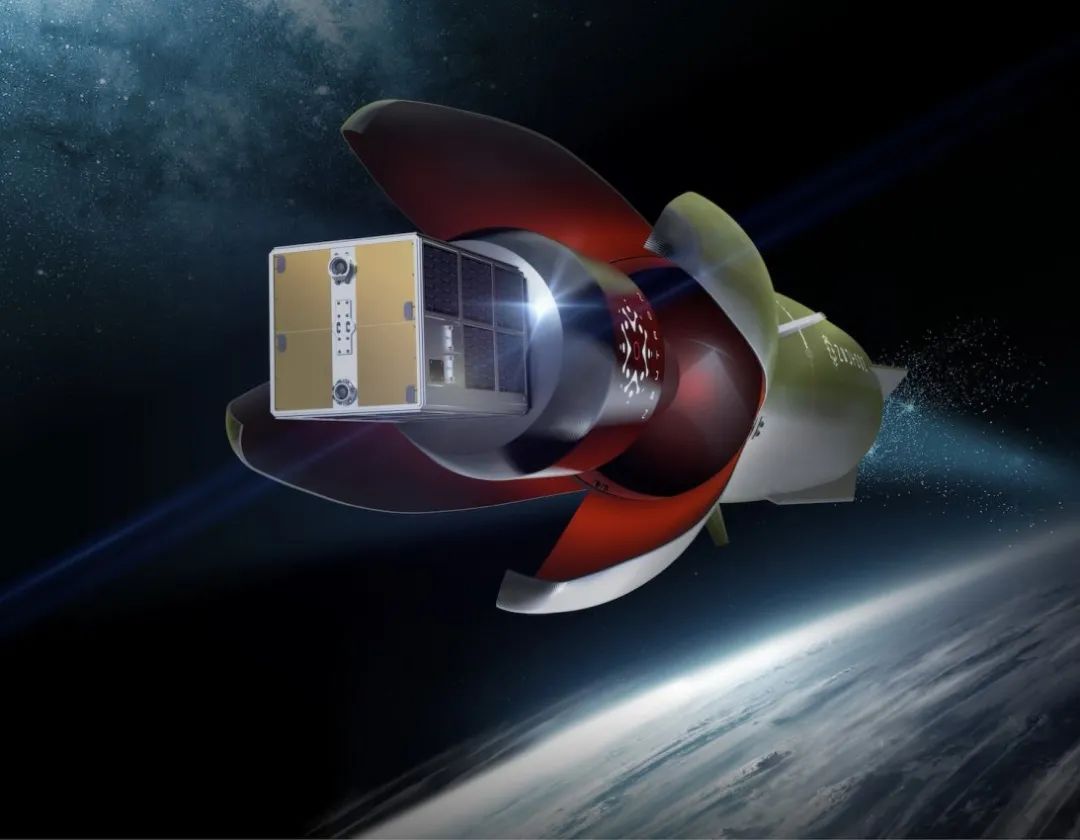

3. The new fairing concept breaks through the conventional design

The unique design of the “Neutron” rocket is also reflected in the fairing called “Hungry Hippo” (Hungry Hippo). The “Hungry Hippo” fairing will become part of the first stage of the rocket and will be fully integrated with the first stage; the “Hungry Hippo” fairing will not be separated from the rocket and fall into the sea like a traditional fairing, but will open up like a hippopotamus. The mouth opened to release the rocket’s second stage and payload, and then closed again and returned to Earth with the first-stage rocket. The rocket landing on the launch pad is a first-stage rocket with a fairing, which can be integrated into a second-stage rocket in a short time and launched again. Adopting the “Hungry Hippo” fairing design can speed up the launch frequency and eliminate the high cost and low reliability of recycling fairings at sea.

4. The second stage of the rocket has high performance characteristics

Due to the “Hungry Hippo” fairing design, the rocket stage 2 will be completely enclosed in the rocket stage and fairing when it is launched. Therefore, the second stage of the “Neutron” rocket will be the lightest second stage in history. Generally, the second stage of the rocket is a part of the outer structure of the launch vehicle, which will be exposed to the harsh environment of the lower atmosphere during launch. By installing the rocket stage and the “Hungry Hippo” fairing, the second stage of the “Neutron” rocket is not required Withstand the pressure of the launch environment, and can significantly reduce weight, thereby achieving higher space performance. Currently, the second stage of the rocket is still designed for one-time use.

5. Rocket engines built for reliability and repeated use

“Neutron” rocket will be powered by a new Archimedes rocket engine. Archimedes is designed and manufactured by Rocket Lab. It is a reusable liquid oxygen/methane gas generator cycle engine that can provide 1 meganewton of thrust and 320 seconds of initial specific impulse (ISP). The “Neutron” rocket uses 7 Archimedes engines in the first stage, and 1 vacuum version of the Archimedes engines in the second stage. The “Neutron” rocket uses lightweight carbon fiber composite structural parts, and there is no need to require the Archimedes engine to have too high performance and complexity. By developing a relatively simple engine with moderate performance, the timetable for development and testing can be greatly shortened.

Post time: Dec-31-2021