FRP is widely used in the field of corrosion resistance. It has a long history in industrially developed countries. The domestic corrosion-resistant FRP has been greatly developed since the 1950s, especially in the past 20 years. The introduction of manufacturing equipment and technology for corrosion-resistant FRP raw materials and products, and the types and applications of corrosion-resistant FRP products are becoming more and more extensive in various fields of the national economy.

1. Widely used in the field of environmental protection

With the development of industry, the problem of environmental pollution has become one of the common concerns of people in the world today. Many countries have invested huge manpower and material resources to devote themselves to the new industrial sector of environmental protection industry.

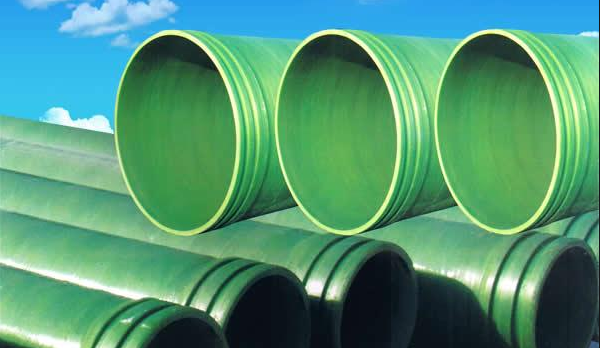

FRP has been widely used in water supply and drainage pipeline engineering. In recent years, more and more waste water and corrosive media types and corrosion strength are constantly increasing, which requires the use of materials with better corrosion resistance, and corrosion-resistant glass fiber reinforced plastic is the best material to meet this demand.

The application of composite materials in environmental protection includes general industrial waste gas treatment, oil-water treatment, sewage treatment with toxic substances, garbage incineration treatment, and urban wastewater deodorization treatment.

2. Widely used in the food industry The excellent corrosion resistance of glass fiber reinforced plastic means that this material has lively and non-polluting characteristics, and it can naturally become a highly clean item, such as the storage of high-purity water, medicine, wine, milk and other optional materials. The United States and Japan have specialized factories for this kind of products, and they have accumulated rich experience in using them. Domestic manufacturers have also been actively following up in recent years, and are likely to catch up. 3. Widely used in the field of chlor-alkali industry The chlor-alkali industry is one of the earliest application fields of FRP as a corrosion-resistant material. At present, FRP has become the main material of the chlor-alkali industry. As early as the early 1950s, FRP was first used to collect heat (93°C), wet chlorine, and organic matter from ink electrodes. This application replaced the phenolic asbestos plastic at the time. Later, FRP was used to replace the cover of the concrete electrolytic cell, which solved the problem of the corroded concrete foam falling into the electrolytic cell. Since then, FRP has been gradually used in various piping systems, gas blast mobility, heat exchanger shells, brine tanks, pumps, pools, floors, wall panels, grilles, handles, railings and other building structures. At the same time, FRP has also begun to enter various fields of the chemical industry.

4. Widely used in the field of papermaking

The paper industry uses wood as raw materials. The papermaking process requires acids, salts, bleaching agents, etc., which have a strong corrosive effect on metals. Only glass fiber reinforced plastic materials can withstand harsh environments such as mycotoxins. FRP has been used in pulp production in some countries. In showing its excellent corrosion resistance.

Post time: Jul-06-2021