Talgo has reduced the weight of high-speed train running gear frames by 50 percent by using carbon fiber reinforced polymer (CFRP) composites. The reduction in train tare weight improves the train’s energy consumption, which in turn increases passenger capacity, among other benefits.

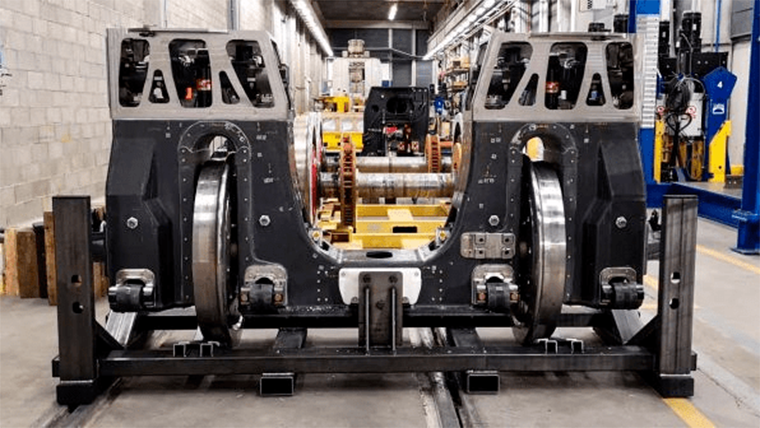

Running gear racks, also known as rods, are the second largest structural component of high-speed trains and have stringent structural resistance requirements. Traditional running gears are welded from steel plates and are prone to fatigue due to their geometry and welding process.

Talgo’s team saw an opportunity to replace the steel running gear frame, and researched a number of materials and processes, finding that carbon fiber-reinforced polymer was the best option.

Talgo successfully completed full-scale verification of structural requirements, including static and fatigue testing, as well as non-destructive testing (NDT). The material meets fire-smoke-toxicity (FST) standards due to hand laying of the CFRP prepreg. Weight reduction is another clear benefit of using CFRP materials.

The CFRP running gear frame was developed for Avril high-speed trains. Talgo’s next steps include running the rodal in real-world conditions for final approval, as well as expanding development of other commuter vehicles. Due to the lighter weight of the trains, the new components will reduce energy consumption and reduce wear and tear on the tracks.

The experience from the rodal project will also contribute to the implementation of a new set of railway standards (CEN/TC 256/SC 2/WG 54) around the acceptance process for new materials.

Talgo’s project is supported by the European Commission through the Shift2Rail (S2R) project. S2R’s vision is to bring to Europe the most sustainable, cost-effective, efficient, time-saving, digital and competitive customer-centric transport mode through railway research and innovation.

Post time: May-17-2022