SABIC, a global leader in the chemical industry, has introduced LNP Thermocomp OFC08V compound, a material ideal for 5G base station dipole antennas and other electrical/electronic applications.

This new compound could help the industry develop lightweight, economical, all-plastic antenna designs that facilitate the deployment of 5G infrastructure. In an era of growing urbanization and smart cities, there is an urgent need for widespread availability of 5G networks to provide fast, reliable connectivity to millions of residents.

“To help realize the promise of 5G’s faster speeds, more data loads, and ultra-low latency, RF antenna manufacturers are revolutionizing their designs, materials and processes,” the person said.

“We are helping our customers simplify the production of RF antennas, which are used in hundreds of arrays within active antenna units. Our newest high-performance LNP Thermocomp compounds help simplify not only by avoiding post-processing production, but also deliver superior performance in several key areas. By continuously developing new materials for 5G infrastructure, SABIC aims to accelerate the expansion of this next-generation network technology.”

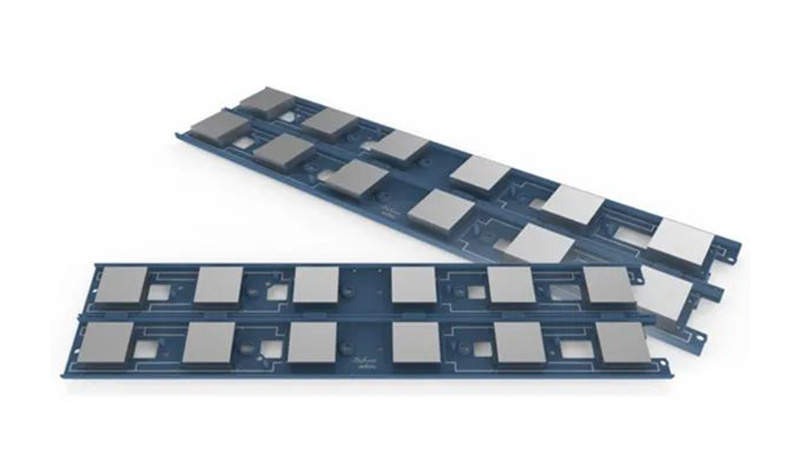

LNP Thermocomp OFC08V compound is a glass fiber reinforced material based on polyphenylene sulfide (PPS) resin. It features excellent electroplating properties using laser direct structuring (LDS), strong layer adhesion, good warpage control, high heat resistance, and stable dielectric and radio frequency (RF) properties. This unique combination of properties enables new injection moldable dipole antenna designs that offer advantages over traditional printed circuit board (PCB) assembly and selective plating of plastics.

Comprehensive performance benefits

The new LNP Thermocomp OFC08V compound is formulated for use in metal plating using LDS. The material has a wide laser processing window, which facilitates plating and ensures uniformity of plating line width, helping to ensure stable and consistent antenna performance. Strong adhesion between plastic and metal layers avoids delamination, even after thermal aging and lead-free reflow soldering. Improved dimensional stability and lower warpage compared to competing glass fiber reinforced PPS grades facilitate smooth fixation of the metallization during LDS, as well as accurate assembly.

Due to these properties, the LNP Thermocomp OFC08V compound has been listed by German laser manufacturing solutions provider LPKF Laser & Electronics as a certified thermoplastic for LDS in the company’s material portfolio.

“All-plastic dipole antennas made with glass fiber-reinforced PPS are replacing traditional designs because they can reduce weight, simplify assembly, and provide higher plating uniformity,” said the person. “However, conventional PPS The material requires a complex metallization process. To address this challenge, the company developed a new, specialized PPS-based compound with LDS capability and high-strength bonding.”

The complex selective electroplating process for plastics that is widely used today involves multiple steps, and the LDS-enabled LNP Thermocomp OFC08V compound offers greater simplicity and higher productivity. After the part is injection molded, LDS only requires laser forming and electroless plating.

In addition, the new LNP Thermocomp OFC08V compound offers all the performance benefits of glass-filled PPS, including high thermal resistance for PCB assembly using surface mount technology, as well as inherent flame retardancy (UL-94 V0 at 0.8 mm). Low dielectric value (dielectric constant: 4.0; dissipation factor: 0.0045) and stable dielectric properties, as well as good RF performance under harsh conditions, help optimize transmission and extend service life.

“The emergence of this advanced LNP Thermocomp OFC08V compound can facilitate improvements in antenna design and stable performance in the field, simplifying the metallization process and reducing system costs for our customers,” the person added.

Post time: Apr-25-2022