Carbon films such as graphene are very light but very strong materials with excellent application potential, but may be difficult to manufacture, usually require a lot of manpower and time-consuming strategies, and the methods are expensive and not environmentally friendly.

With the production of a large amount of graphene, in order to overcome the difficulties encountered in implementing current extraction methods, researchers at Ben Gurion University of the Negev in Israel have developed a “green” graphene extraction method that can be applied to A wide range of fields, including optics, electronics, ecology and biotechnology.

Researchers used mechanical dispersion to extract graphene from the natural mineral striolite. They found that the mineral hypophyllite shows good prospects in producing industrial-scale graphene and graphene-like substances.

The carbon content of hypomphibole may be different. According to the carbon content, hypomphibole can have different application potentials. Some types may be used for their catalytic properties, while other types have bactericidal properties.

The structural characteristics of hypopyroxene determine their application in the oxidation-reduction process, and it can also be used for blast furnace production and ferroalloy production of cast (high silicon) cast iron.

Due to its physical and mechanical properties, bulk density, good strength and wear resistance, hypophyllite also has the ability to adsorb a variety of organic substances, so it can be actually used as a filter material. It also demonstrated the ability to eliminate free radical particles that may contaminate water sources.

The hypopyroxene shows the ability to disinfect and purify water from bacteria, spores, simple microorganisms and blue-green algae. Due to its high catalytic and reducing properties, magnesia is often used as an adsorbent for wastewater treatment.

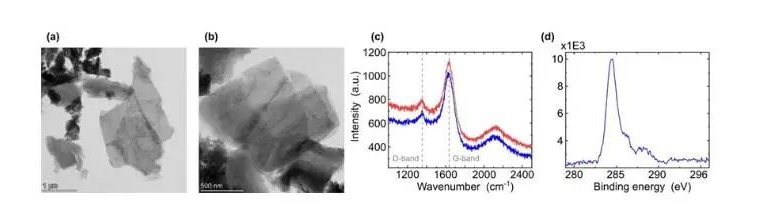

(a) X13500 magnification and (b) X35000 magnification TEM image of the dispersed hypophyllite sample. (c) Raman spectrum of the treated hypophyllite and (d) XPS spectrum of the carbon line in the hypophyllite spectrum

Graphene extraction

To prepare the rocks for graphene extraction, the two used a scanning electron microscope (SEM) to examine the heavy metal impurities and porosity in the samples. They also applied other laboratory methods to check the general structural composition and the presence of other minerals in the hypomphibole.

After sample analysis and preparation were completed, the researchers were able to extract graphene from the diorite after mechanically processing the sample from Karelia using a digital ultrasonic cleaner.

Since a large number of samples can be processed using this method, there is no risk of secondary contamination, and subsequent sample processing methods are not required.

Since the extraordinary properties of graphene have been widely known in the wider scientific research community, many production and synthesis methods have been developed. However, many of these methods are either multi-step processes or require the use of chemicals and strong oxidizing and reducing agents.

Although graphene and other carbon films have shown great application potential and achieved relative R&D success, the processes using these materials are still under development. Part of the challenge is to make graphene extraction cost-effective, which means that finding the right dispersion technology is the key.

This dispersion or synthesis method is laborious and environmentally unfriendly, and the strength of these technologies can also cause defects in the produced graphene, thereby reducing the expected excellent quality of graphene.

The application of ultrasonic cleaners in graphene synthesis eliminates the risks and costs associated with multi-step and chemical methods. Applying this method to the natural mineral hypophyllite paved the way for a new environmentally friendly way of producing graphene.

Post time: Nov-04-2021