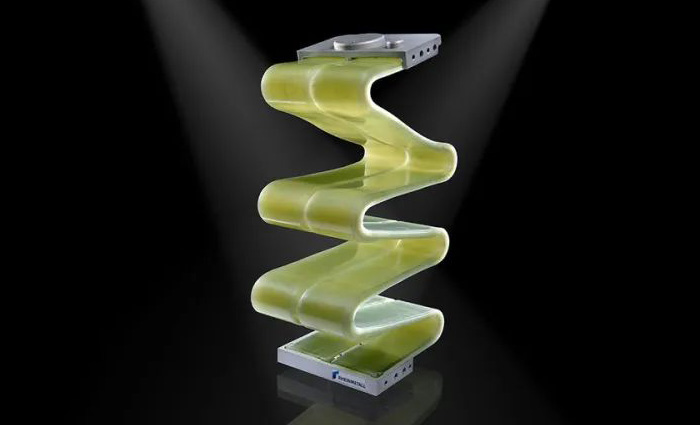

According to foreign media reports, Rheinmetall has developed a new fiberglass suspension spring and has partnered with a high-end OEM to use the product in prototype test vehicles. This new spring features a patented design that significantly reduces unsprung mass and improves performance.

Suspension springs connect the wheels to the chassis and thus play an important role in the safety and handling of the vehicle. Compared to conventional steel coil springs, the new glass fiber-reinforced composite spring can reduce unsprung mass by up to 75%, making it particularly suitable for range-optimized electric vehicles.

In addition to reducing weight, the development team placed great emphasis on maximum pitch and roll stability, high inherent damping of the material and ensuring optimum noise, vibration and harshness characteristics. Compared to traditional steel springs, fiberglass reinforced springs are also resistant to corrosion because plastic can only be corroded by certain chemicals, but not by oxygen and water.

The spring can be arranged in the same installation space as a standard spring and has excellent fatigue strength, including very good emergency handling characteristics, allowing the vehicle to continue driving.

Post time: May-10-2022