Glass fiber, referred to as “glass fiber”, is a new reinforcing material and metal substitute material. The diameter of the monofilament is several micrometers to more than twenty micrometers, which is equivalent to 1/20-1/5 of the hair strands. Each bundle of fiber strands is composed of imported roots or even thousands of monofilaments.

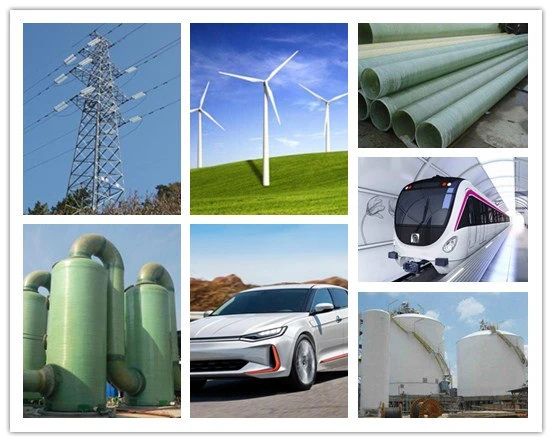

Glass fiber has the characteristics of non-combustibility, corrosion resistance, heat insulation, sound insulation, high tensile strength, and good electrical insulation. It has a wide range of uses and has broad applications in construction, automobiles, ships, chemical pipelines, rail transit, wind power and other fields. Application prospects.

The glass fiber production process is to grind and homogenize raw materials such as pyrophyllite, and directly melt them in a high-temperature furnace to make glass liquid, and then wire drawing. The wire drawing machine is the key equipment for glass fiber forming, and it is a machine that draws molten glass into wire. The molten glass flows down through the leakage plate, and is stretched at a high speed by the wire drawing machine, and is wound into a certain direction. After subsequent drying and winding, there will be a tough glass fiber product.

Post time: Jun-04-2021