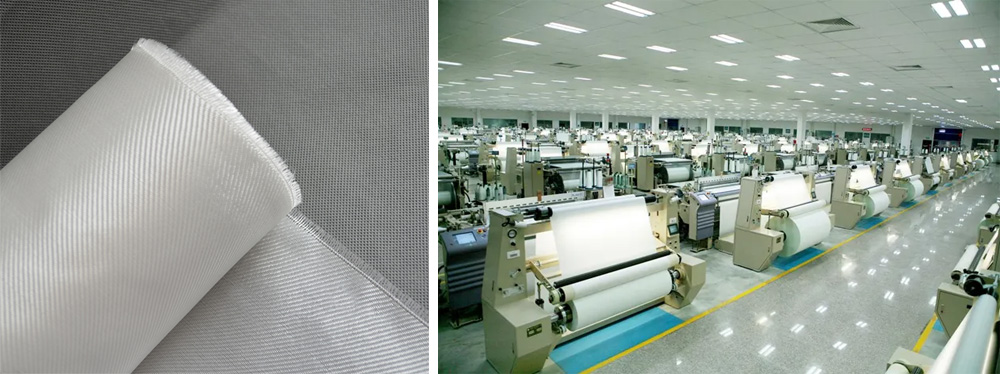

(1) Heat-insulating functional material products

The main traditional process methods for aerospace high-performance structural functional integrated heat-insulating materials are RTM (Resin Transfer Molding), molding, and layup, etc. This project adopts a new multiple molding process.

RTM Processing:

① Laying of fiber cloth: the prepared quartz fiber cloth is put into the mold cavity at one time;

② Resin injection: resin and catalyst are mixed in the static mixer at the front of the injection gun and injected into the mold cavity covered with fiber cloth.

③ Resin curing: the mold cavity is heated in order to accelerate the curing of the resin;

(iv) Product demolding: After the resin is cured and molded, the mold is opened to obtain the final composite component.

After the RTM (Resin Transfer Molding) process, the quartz fiber cloth is processed and set with the metal shell, and the product after the set is qualified after the performance test, which is the finished product.

(2)Wave-transparent composite materials

Quartz fiber reinforced ceramic wave-transparent composites prepared by organic precursor impregnation cracking method (PIP).PIP method is to use organic precursor impregnated fiber preforms, and then pyrolysis, the production of quartz fiber matrix deposited into the preform blanks on the billet, in the billet after spray painting treatment for its inspection, inspection and qualification that is the finished product. In order to ensure that the material surface of the required densification temperature is much lower than the traditional hot press sintering process, can minimize the damage to the quartz fibers, and has the characteristics of near-net shaping, especially suitable for the preparation of large-size wave-transparent material components.

(3) Special insulation materials

The quartz fiber cloth will be prepared into the mold cavity, the resin will be injected into the mold cavity so that it is full of fiber cloth mold cavity, heating the mold cavity in order to accelerate the resin curing, resin curing molding, open the mold and can obtain the final special insulating functional materials.

Post time: Nov-11-2024