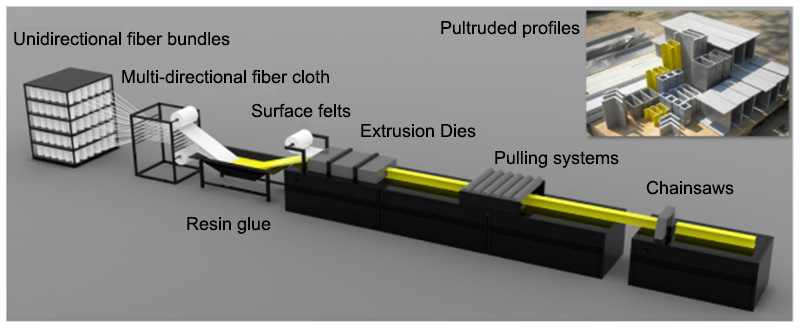

Fiber-reinforced composite pultruded profiles are composite materials made of fiber-reinforced materials (such as glass fibers, carbon fibers, basalt fibers, aramid fibers, etc.) and resin matrix materials (such as epoxy resins, vinyl resins, unsaturated polyester resins, polyurethane resins, etc.) prepared by pultrusion process. Compared with traditional building materials (such as steel and concrete), pultruded profiles have the advantages of light weight, high strength, corrosion resistance, low carbon and other advantages, pultruded profiles structure of the whole life cycle maintenance costs are much lower than the same type of steel and concrete structures, pultruded profiles in civil engineering and construction, new energy sources, machinery and automobile manufacturing, aerospace and other fields show a strong potential for application.

Fields of application

Pultruded profiles are used in civil engineering construction (e.g. footbridges, frame structures, etc.), new energy (e.g. wind power, photovoltaic, etc.), machinery manufacturing (e.g. cooling towers, non-magnetic medical structures, etc.), and automobile manufacturing (e.g. crash beams, battery packs, etc.). Pultruded profiles have significant advantages in realizing structural lightweight, high bearing capacity reserve, high durability and low carbon emission.

Characteristic advantages

1. Exterior frame beams for high-rise buildings: 75% reduction in structural deadweight compared to steel structures; 73% reduction in carbon emissions; significant reduction in the cost of construction measures; the structure is highly corrosion-resistant in offshore environments, and has low whole-life-cycle maintenance costs;

2. Sound barriers for urban rail transit: the structure’s self-weight is expected to be reduced by 40~50%, with convenient construction and low carbon emissions; low structural vibration and reduced secondary noise; the structure is highly corrosion-resistant in outdoor environments, with low whole-life-cycle maintenance costs;

3. PV borders and supports: mechanical properties higher than traditional aluminum alloy materials; strong salt spray and chemical corrosion resistance; good electrical insulation, reducing the possibility of forming leakage circuits and improving the power generation efficiency of the panels;

4. photovoltaic carport: the structure has strong corrosion resistance in the outdoor environment and low maintenance cost; the structure is light in self-weight and convenient in construction and installation; good electrical insulation reduces the possibility of forming leakage circuits and improves the power generation efficiency of the battery panels;

5. Container house: the weight is greatly reduced compared to metal structure; inorganic non-metallic material with good heat preservation; good corrosion and frost resistance; excellent seismic and wind resistance under equal stiffness design;

Post time: Aug-19-2024