The hosting of the Beijing Winter Olympics has attracted worldwide attention. A series of ice and snow equipment and core technologies with independent intellectual property rights of carbon fiber are also amazing.

Snowmobiles and snowmobile helmets made of TG800 carbon fiber

In order to make the “F1 on ice” run at high speed, the materials used in the body of the snowmobile require light weight and high strength, and such materials are also widely used in the aerospace field. Therefore, the manufacture of snowmobiles is aimed at carbon fiber composite materials. It is the first new material to be applied and developed in the aerospace field, and uses the high-strength grade domestic TG800 aerospace-grade carbon fiber composite material. After using carbon fiber composite materials, the snowmobile can reduce the weight of the body to the greatest extent and lower the center of gravity on the premise of ensuring the safety of the athletes, so that the snowmobile can slide more smoothly. According to reports, the body weight of the double sled made of carbon fiber composite material is only about 50 kilograms. The high strength and unique energy-absorbing properties of the material can also protect athletes from being injured in a crash.

Carbon fiber puts a “coat” on the “flying” torch of the Beijing 2022 Winter Olympics

This is the first time in the world that the Olympic torch shell is made of carbon fiber composite materials, which solves the technical problem that the torch needs to be resistant to high temperature when burning hydrogen fuel, making it “light, solid, and beautiful” and so on. It can achieve hydrogen temperatures higher than 800 degrees Celsius. Compared with the cold metal torch shell, “Flying” makes the torchbearers feel warmer and helps the “Green Olympics” when used normally in a combustion environment.

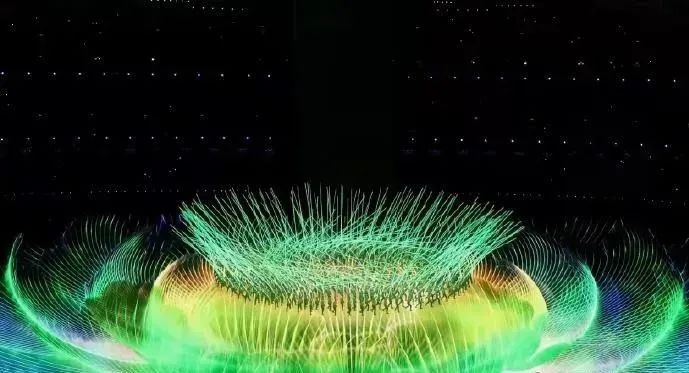

The light-emitting rod used for the opening ceremony is made of carbon fiber composite material

It is 9.5 meters long, 3.8 cm in diameter at the head end, 1.8 cm in diameter at the end, and weighs 3 catties and 7 taels. This seemingly ordinary rod is not only full of technology, but also full of Chinese aesthetics that combine rigidity and softness.

Carbon fiber hydrogen storage tank

The first batch of 46 hydrogen energy commuter buses all use 165L hydrogen storage cylinders, and the designed cruising range can reach 630 kilometers.

The first generation of domestic 3D printed high-performance carbon fiber composite speed skates

Compared with China’s high-end speed skating shoes, the weight of carbon fiber skates is reduced by 3%-4%, and the peel strength of the skates is increased by 7%.

Carbon fiber hockey stick

The hockey stick base carbon fiber composite material adopts a process method of mixing a fluid molding agent when making carbon fiber cloth, so as to reduce the fluidity of the fluid molding agent to below a preset threshold, and control the quality error of the carbon fiber cloth to ±1g/m2 -1.5g/m2; put the carbon fiber cue base made of carbon fiber cloth into the mold, the inflation pressure of the mold is controlled at 18000Kpa to 23000Ka, and the carbon fiber cue base is heated to shape the ice hockey stick. The fluid forming agent is used to adhere to the surface of the carbon fiber cloth, on the one hand, it increases the toughness of the carbon fiber cloth, and on the other hand, it improves the overall structural strength of the club. By providing a low-fluidity fluid molding agent, and the inflation pressure of the mold is constant, it can ensure that there is still enough fluid molding agent attached to the surface of the carbon fiber club substrate, and participate in the subsequent molding process, the sufficient fluid molding agent guarantees The toughness of the hockey stick makes it difficult for the player to crack or break the hockey stick when swinging the hockey stick, ensuring that the hockey stick is strong and durable.

Carbon Fiber Heating Cable Helps Heating Winter Olympic Village Apartments

In order to protect athletes from the cold in winter, in Zhangjiakou Winter Olympic Village, a new type of prefabricated exterior wall panels and carbon fiber heating cables were installed in the athletes’ apartment, which is green and warm and comfortable. A carbon fiber heating cable is laid under the floor of the athlete’s apartment in the Winter Olympic Village, and electricity is used for heating, which directly converts electrical energy into heat energy to reduce heat loss. All the electricity used comes from wind power generation in Zhangjiakou, which is clean, renewable, and environmentally friendly. When the carbon fiber heating cable is working, it will release far infrared rays, which has a good physiotherapy effect on the rehabilitation of athletes and the activation of meridians.

Post time: Feb-21-2022