Carbon fiber + “wind power”

Carbon fiber reinforced composite materials can play the advantage of high elasticity and light weight in large wind turbine blades, and this advantage is more obvious when the outer size of the blade is larger.

Compared with glass fiber material, the weight of the blade using carbon fiber composite material can be reduced by at least about 30%. The reduction of blade weight and the increase of stiffness is beneficial to improve the aerodynamic performance of the blade, reduce the load on the tower and the axle, and make the fan more stable. The power output is more balanced and stable, and the energy output efficiency is higher.

If the electrical conductivity of the carbon fiber material can be effectively utilized in the structural design, the damage to the blades caused by lightning strikes can be avoided. Moreover, the carbon fiber composite material has good fatigue resistance, which is conducive to the long-term work of wind blades in harsh weather conditions.

Carbon fiber + “lithium battery”

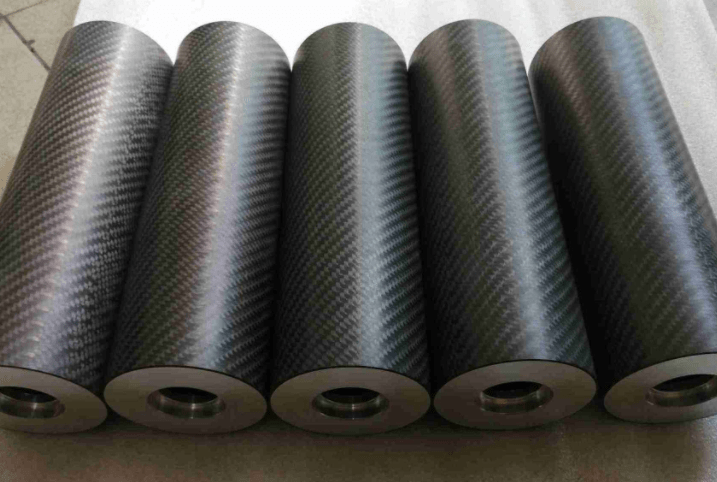

In the manufacture of lithium batteries, a new trend has been formed in which carbon fiber composite material rollers replace traditional metal rollers on a large scale, and take “energy saving, emission reduction and quality improvement” as the guide. The application of new materials is conducive to increasing the added value of the industry and further improving product market competitiveness.

Carbon fiber + “photovoltaic”

The characteristics of high strength, high modulus and low density of carbon fiber composites have also received corresponding attention in the photovoltaic industry. Although they are not as widely used as carbon-carbon composites, their application in some key components is also gradually advancing. Carbon fiber composite materials to make silicon wafer brackets, etc.

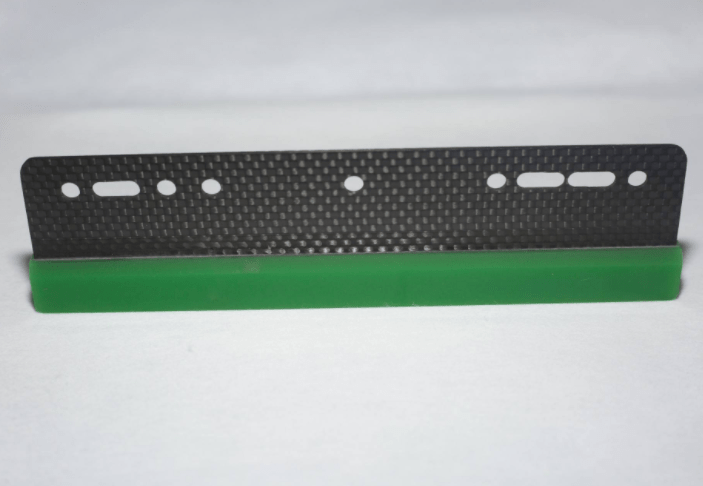

Another example is the carbon fiber squeegee. In the production of photovoltaic cells, the lighter the squeegee, the easier it is to be finer, and the good screen printing effect has a positive effect on improving the conversion effect of photovoltaic cells.

Carbon fiber + “hydrogen energy”

The design mainly reflects the “lightweight” of carbon fiber composite materials and the “green and efficient” characteristics of hydrogen energy. The bus uses carbon fiber composite materials as the main body material and uses “hydrogen energy” as the power to refuel 24 kg of hydrogen at a time. The cruising range can reach 800 kilometers, and it has the advantages of zero emission, low noise and long life.

Through the forward design of the carbon fiber composite body and the optimization of other system configurations, the actual measurement of the vehicle is 10 tons, which is more than 25% lighter than other vehicles of the same type, effectively reducing the hydrogen energy consumption during operation. The release of this model not only promotes the “hydrogen energy demonstration application”, but also is a successful case of the perfect combination of carbon fiber composite materials and new energy.

Through the forward design of the carbon fiber composite body and the optimization of other system configurations, the actual measurement of the vehicle is 10 tons, which is more than 25% lighter than other vehicles of the same type, effectively reducing the hydrogen energy consumption during operation. The release of this model not only promotes the “hydrogen energy demonstration application”, but also is a successful case of the perfect combination of carbon fiber composite materials and new energy.

Post time: Mar-16-2022