According to the shape and length, glass fiber can be divided into continuous fiber, fixed-length fiber and glass wool; according to glass composition, it can be divided into alkali-free, chemical resistance, medium alkali, high strength, high elastic modulus and alkali resistance (alkali resistance) fiberglass, etc.

The main raw materials for glass fiber production are: quartz sand, alumina and pyrophyllite, limestone, dolomite, boric acid, soda ash, mirabilite, fluorite, etc. The production methods are roughly divided into two categories: one is to directly make molten glass into fibers; the other is to first make molten glass into glass balls or rods with a diameter of 20 mm, and then heat and remelt in various ways to make glass balls or rods with a diameter of 3 to 3 mm. 80μm very fine fibers. The infinitely long fibers drawn by the mechanical drawing method of platinum alloy plates are called continuous glass fibers, commonly known as long fibers. Discontinuous fibers made by rollers or air flow, called fixed-length glass fibers, commonly known as short fibers

Glass fibers are classified into different grades according to their composition, properties and uses. According to the regulations of the standard grade, E-grade glass fiber is widely used and widely used in electrical insulating materials; S-grade is a special fiber.

The glass used in the production of fiberglass is different from the glass used in other glass products. Generally, the glass compositions for fibers that have been commercialized are as follows:

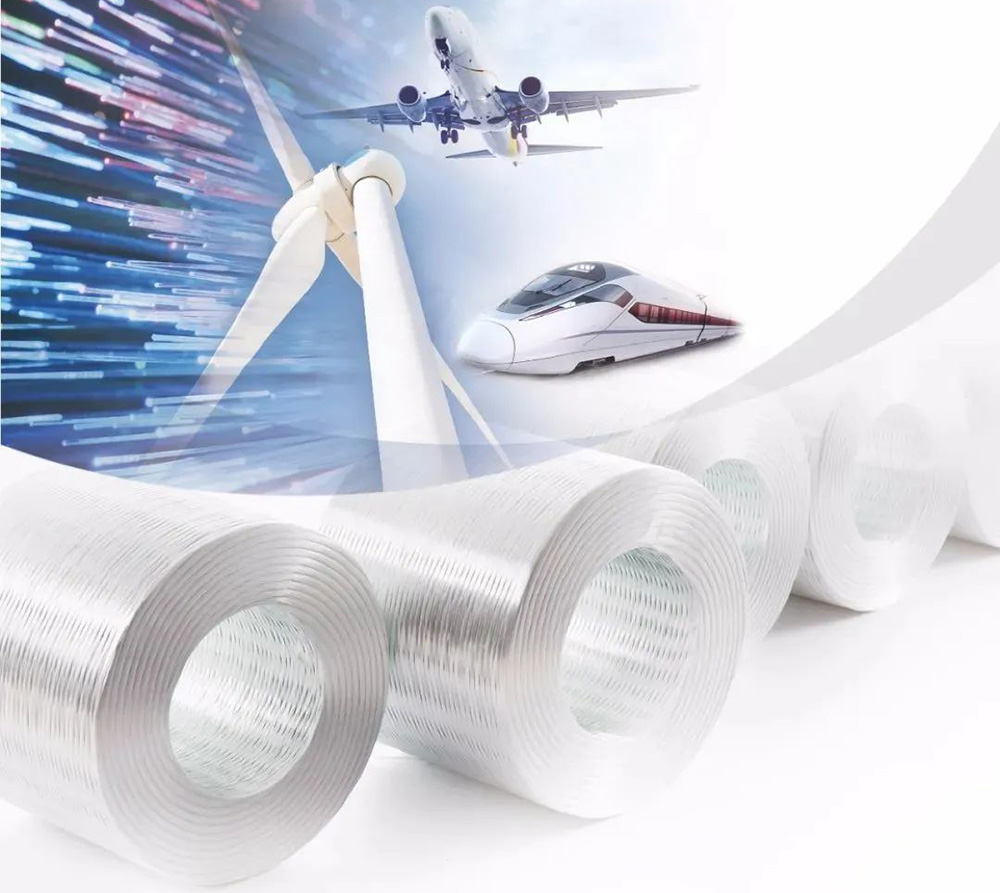

High strength and high modulus fiberglass

It is characterized by high strength and high modulus. Its single fiber tensile strength is 2800MPa, which is about 25% higher than that of alkali-free glass fiber, and its elastic modulus is 86000MPa, which is higher than E-glass fiber. The FRP products produced with them are mostly used in military industry, aerospace, high-speed rail, wind power, bulletproof armor and sports equipment.

AR fiberglass

Also known as alkali-resistant glass fiber, alkali-resistant glass fiber is a reinforcing material for glass fiber reinforced (cement) concrete (referred to as GRC), a high-standard inorganic fiber, and an ideal substitute for steel and asbestos in non-load-bearing cement components. The characteristics of alkali-resistant glass fiber are good alkali resistance, can effectively resist the erosion of high alkali substances in cement, strong gripping force, high elastic modulus, impact resistance, tensile and bending strength, non-flammable, frost-resistant, temperature-resistant , strong humidity change ability, excellent crack resistance and impermeability, strong designability, easy molding, etc., alkali-resistant glass fiber is a new type of green and environmentally friendly reinforcement widely used in high-performance reinforced (cement) concrete Material.

D glass

Also known as low dielectric glass, it is used to produce low dielectric glass fibers with good dielectric strength.

In addition to the above glass fiber components, a new alkali-free glass fiber is now available, which is completely free of boron, thereby reducing environmental pollution, but its electrical insulating properties and mechanical properties are similar to traditional E glass. In addition, there is a glass fiber with double glass composition, which has been used in the production of glass wool, and it is also said to have potential for fiberglass reinforcement. In addition, there is fluorine-free glass fiber, which is an improved alkali-free glass fiber developed for environmental protection requirements.

In addition to the above glass fiber components, a new alkali-free glass fiber is now available, which is completely free of boron, thereby reducing environmental pollution, but its electrical insulating properties and mechanical properties are similar to traditional E glass. In addition, there is a glass fiber with double glass composition, which has been used in the production of glass wool, and it is also said to have potential for fiberglass reinforcement. In addition, there is fluorine-free glass fiber, which is an improved alkali-free glass fiber developed for environmental protection requirements.

You can divide fiberglass into different categories, depending on the raw materials used and their proportions.

Here are 7 different types of fiberglass and their applications in everyday products:

Alkali glass (A-glass)

Soda glass or soda lime glass. It is the widely used fiberglass type. Alkali glass accounts for about 90% of all manufactured glass. It is the most common type and is used to make glass containers, such as cans and bottles for food and beverages, and window glass.

Baking utensils made of tempered soda lime glass are also a perfect example of A glass. It’s affordable, highly feasible, and fairly hard. A-type glass fibers can be re-melted and re-softened multiple times and are ideal glass fiber types for glass recycling.

Alkali-resistant glass AE-glass or AR-glass

AE or AR glass stands for alkali resistant glass, which is specially used for concrete. It is a composite material composed of zirconia.

The addition of zirconia, a hard, heat-resistant mineral, makes this fiberglass suitable for use in concrete. AR-glass prevents concrete cracking by providing strength and flexibility. Also, unlike steel, it does not rust easily.

Chemical glass

C-glass or chemical glass is used as a surface tissue for the outer layer of laminates for pipes and containers for storing water and chemicals. Due to the high concentration of calcium borosilicate used in the glass formulation process, it exhibits maximum chemical resistance in corrosive environments.

C-glass maintains chemical and structural balance in any environment and is fairly resistant to alkaline chemicals.

Dielectric glass

Dielectric glass (D-glass) fibers are commonly used in appliances, cookware, and the like. It is also an ideal type of fiberglass due to its low dielectric constant. This is due to the presence of boron trioxide in its composition.

Electronic glass

E-glass or E-fiberglass cloth is an industry standard that offers a balance between performance and cost. It is a lightweight composite material with applications in aerospace, marine and industrial environments. E-glass’ properties as a reinforcing fiber have made it a darling of commercial products such as planters, surfboards, and boats.

E-glass in glass wool fibers can be made into any shape or size using a very simple manufacturing technique. In pre-production, the properties of E-glass fiber make it clean and safe to work with.

Structural glass

Structural glass (S glass) is known for its mechanical properties. The trade names R-glass, S-glass and T-glass all refer to the same type of fiberglass. Compared with E-glass fiber, it has higher tensile strength and modulus. This fiberglass is designed for use in the defense and aerospace industries.

It is also used in rigid ballistic armor applications. Because this type of glass fiber is high-performance, it is only used in specific industries with limited production volumes. It also means that S-glass can be expensive.

Advantex fiberglass

This type of fiberglass is widely used in the oil, gas and mining industries, as well as in power plants and marine applications (sewage and wastewater treatment systems). It combines the mechanical and electrical properties of E-glass with the acid corrosion resistance of E, C, R type glass fibers. It is used in environments where structures are more susceptible to corrosion.

Post time: May-11-2022