Raw Material Preparation

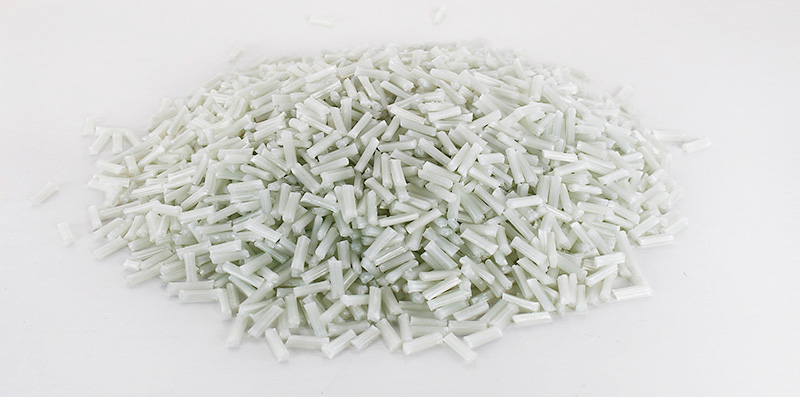

Before producing long fiberglass reinforced polypropylene composites, adequate raw material preparation is required. The main raw materials include polypropylene (PP) resin, long fibersglass (LGF), additives and so on. Polypropylene resin is the matrix material, long glass fibers as reinforcing materials, additives including plasticizers, stabilizers, lubricants, etc., used to improve the processing properties and mechanical properties of the material.

Fiberglass Infiltration

In the glass fiber infiltration stage, the long glass fibers are infiltrated in the polypropylene resin. This step usually adopts pre-impregnation or direct mixing method, so that the glass fiber is fully impregnated by the resin, laying the foundation for the subsequent preparation of composite materials.

Fiberglass Dispersion

In the fiberglass dispersion stage, the infiltrated long glass fibers are further mixed with the polypropylene resin in a mixing facility to ensure that the fibers are uniformly dispersed in the resin. This step is crucial to the performance of the composite material, and it is necessary to ensure that the fiber is well dispersed in the resin.

Injection Molding

In the injection molding stage, the well-mixed composite material is molded through an injection molding machine. During the injection molding process, the material is heated and injected into the mold, and then cooled to form a composite product with a specific shape and size.

Heat Treatment

Heat treatment is an important part of the production process of long fiberglass reinforced polypropylene composites. Through heat treatment, the mechanical properties and stability of the composite can be further improved. Heat treatment typically involves heating, holding and cooling steps to achieve optimum performance of the composite.

Cooling and sizing

In the cooling and shaping stage, the heat-treated composite products are cooled by the cooling equipment, so that the products are shaped. This step is essential to ensure the dimensional stability and surface quality of the product.

Post-processing

Post-processing is the further processing of the cooled and shaped composite products, such as trimming, grinding, etc., in order to remove burrs and imperfections on the surface of the products, and to improve the appearance and dimensional accuracy of the products.

Quality Inspection

Finally, the long glass fiber reinforced polypropylene composites are inspected for quality. The quality inspection includes appearance inspection, size measurement, mechanical property test, etc., to ensure that the products meet the design requirements and relevant standards. The quality inspection can ensure that the composite products have good performance and stability.

The production process of long fiberglass reinforced polypropylene composites includes the steps of raw material preparation, fiberglass infiltration, fiberglass dispersion, injection molding, heat treatment, cooling and shaping, product post-treatment and quality inspection. Through the strict control and implementation of this process, high quality long fiberglass reinforced polypropylene composite products can be produced.

Post time: Oct-14-2024