The World Health Organization estimates that more than 785 million people lack a clean source of drinking water. Even though 71% of the earth’s surface is covered by sea water, we cannot drink the water.

Scientists around the world have been working hard to find an effective way to desalinate seawater cheaply. Now, a group of South Korean scientists may have found a way to purify seawater in a matter of minutes.

The fresh water needed for human activities only accounts for 2.5% of the total available water resources on the earth. Changing climatic conditions have led to changes in precipitation and drying up of rivers, prompting countries to declare water shortages for the first time in their history. It is not surprising that desalination is the easiest way to solve this problem. But these processes have their own limitations.

When using a membrane to filter seawater, the membrane must be kept dry for a long time. If the membrane becomes wet, the filtration process will become ineffective and allow large amounts of salt to pass through the membrane. For long-term operation, gradual wetting of the membrane is often observed, which can be solved by replacing the membrane.

When using a membrane to filter seawater, the membrane must be kept dry for a long time. If the membrane becomes wet, the filtration process will become ineffective and allow large amounts of salt to pass through the membrane. For long-term operation, gradual wetting of the membrane is often observed, which can be solved by replacing the membrane.

The hydrophobicity of the membrane is helpful because its design does not allow water molecules to pass through.

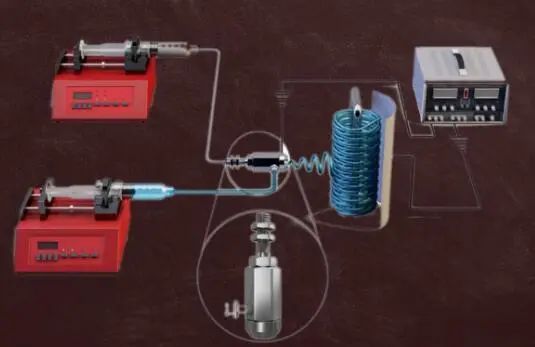

Instead, a temperature difference is applied to the two sides of the film to evaporate water from one end into water vapor. This membrane allows water vapor to pass through and then condenses to the cooler side. Called membrane distillation, this is a commonly used membrane desalination method. Since the salt particles are not converted to gaseous state, they are left on one side of the membrane, providing high-purity water on the other side.

South Korean researchers also used silica aerogel in their membrane manufacturing process, which further enhances the flow of water vapor through the membrane, resulting in faster access to desalinated water. The team tested their technology for 30 consecutive days and found that the membrane can continuously filter out 99.9% of salt.

Instead, a temperature difference is applied to the two sides of the film to evaporate water from one end into water vapor. This membrane allows water vapor to pass through and then condenses to the cooler side. Called membrane distillation, this is a commonly used membrane desalination method. Since the salt particles are not converted to gaseous state, they are left on one side of the membrane, providing high-purity water on the other side.

South Korean researchers also used silica aerogel in their membrane manufacturing process, which further enhances the flow of water vapor through the membrane, resulting in faster access to desalinated water. The team tested their technology for 30 consecutive days and found that the membrane can continuously filter out 99.9% of salt.

Post time: Jul-09-2021