It is understood that the reason why the double-decker train has not gained a lot of weight is due to the lightweight design of the train. The car body uses a large number of new composite materials with light weight, high strength and corrosion resistance. There is a famous saying in the aircraft manufacturing industry: “Strive to reduce every gram of weight.” Also in the high-speed rail trains, subways and other rail transit fields, lightweighting has particularly important practical and economic significance for weight reduction, speed increase, and energy consumption reduction. Benefit; and the application of new composite materials just provides an important material guarantee for the lightweight of interior materials in the rail transit field.

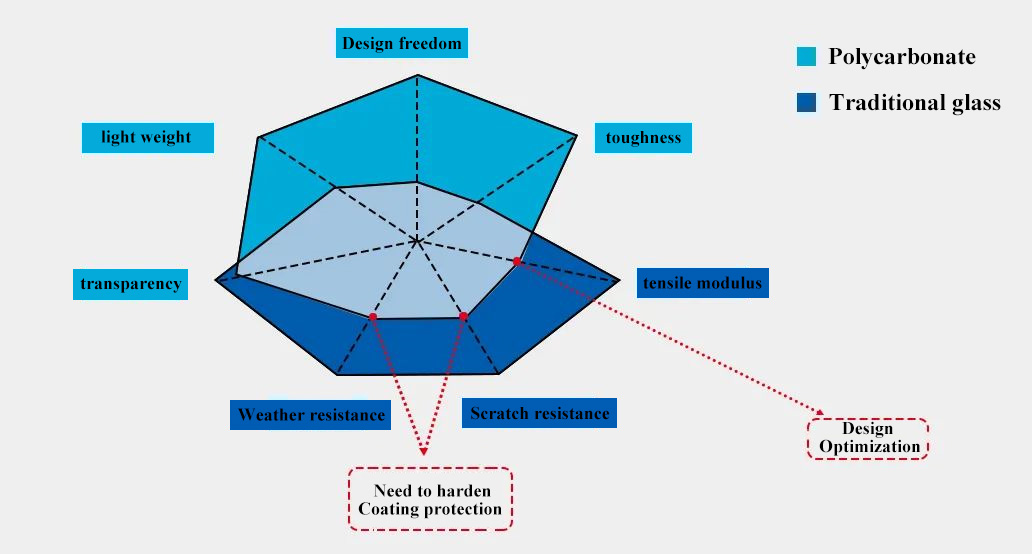

This time, one of the lightweight materials designed and used in the interior of the double-action train-thermoplastic polycarbonate PC composite material, is mainly used in the upper and lower layers of the carriage and the end side wall panels and side roof panels; at the same time, It is also the first domestic overseas project to use thermoplastic PC composites in a large area in the passenger compartment of the EMU; it is completed by processes such as clean and dust-free extrusion, high-pressure hollow thermoforming, five-axis CNC intelligent processing, and modular customization; product effects Meet the requirements of high rigidity, matte, special color and surface texture.

Compared with interior materials such as glass and glass fiber reinforced plastics that have been maturely used in the cabin and are familiar to the public, thermoplastic PC composites may have a sense of “distance”, which is mainly due to the trend and rhythm of the development of new materials in the development process of the industrial age; With the green environmental protection and sustainable development concepts of “plastics instead of glass” and “plastics instead of rigidity”, as a lightweight material that meets major industry standards, thermoplastic PC composites can be streamlined by integrating components. Production, avoiding secondary operations, recyclability, and weight reduction make transportation costs, labor costs, and other ways to reduce system costs significantly; at the same time, it can also meet the strict and complex global standards of fire, smoke and toxicity testing; Therefore, in recent years, it has gradually entered the field of rail transit car body interiors, and has been unanimously recognized by major rail transit vehicle OEMs and supporting factories; at the same time, in the rail transit industry in China and the world, thermoplastic PC composite materials have begun to be realized Domestically produced in-house.

At present, a new wave of technological innovation represented by information networks, intelligent manufacturing, new energy and new materials is emerging around the world, and a new round of all-round changes in the field of global rail transit equipment is gestating. Conform to the new development direction of the high-end manufacturing field of rail transit, adhere to the mission of “Let new materials and intelligent products improve the quality of human life”, work with upstream and downstream partners and industry colleagues to promote a safer and greener world-class new material technology , A smart and efficient world of transportation, helping the high-quality development of China’s rail transit industry.

Post time: Jul-05-2021