Low price for End To End Fiberglass Smc Roving - E-glass Assembled Panel Roving – Beihai Fiberglass

Low price for End To End Fiberglass Smc Roving - E-glass Assembled Panel Roving – Beihai Fiberglass Detail:

E-glass Assembled Panel Roving

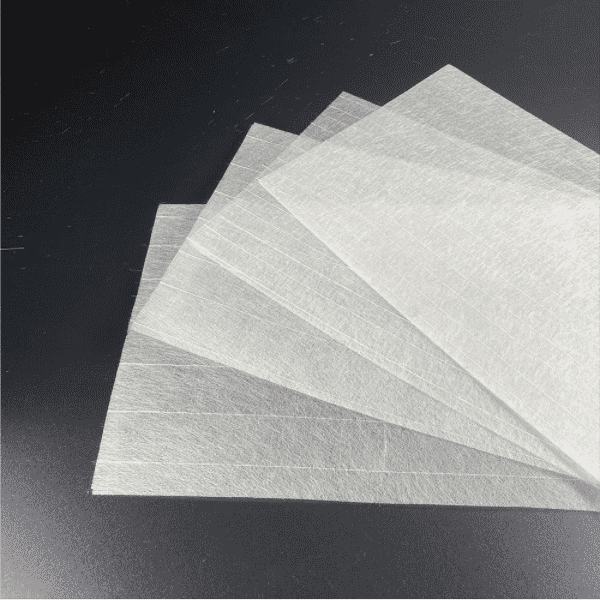

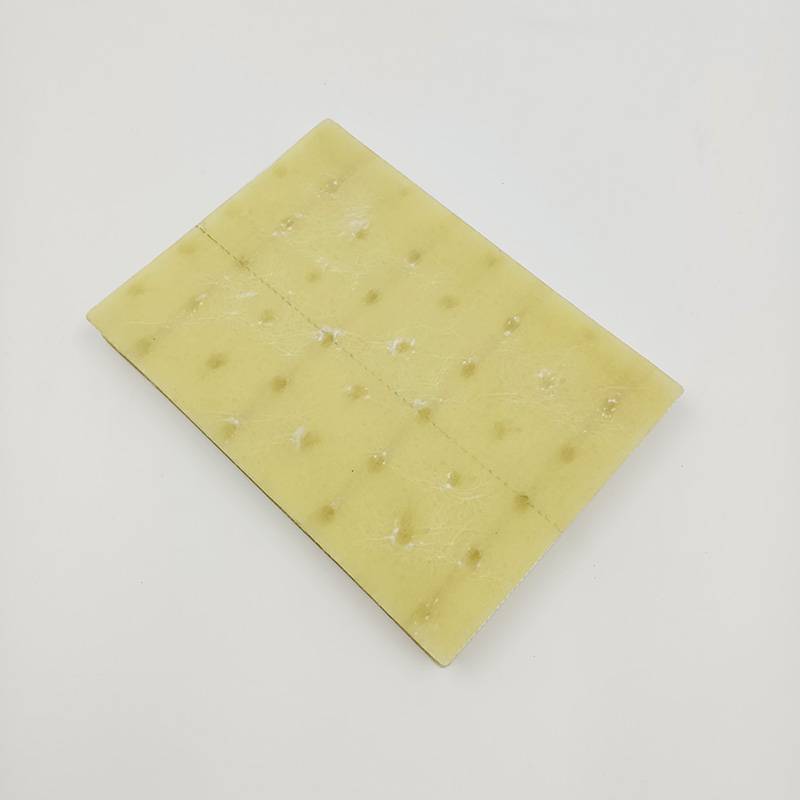

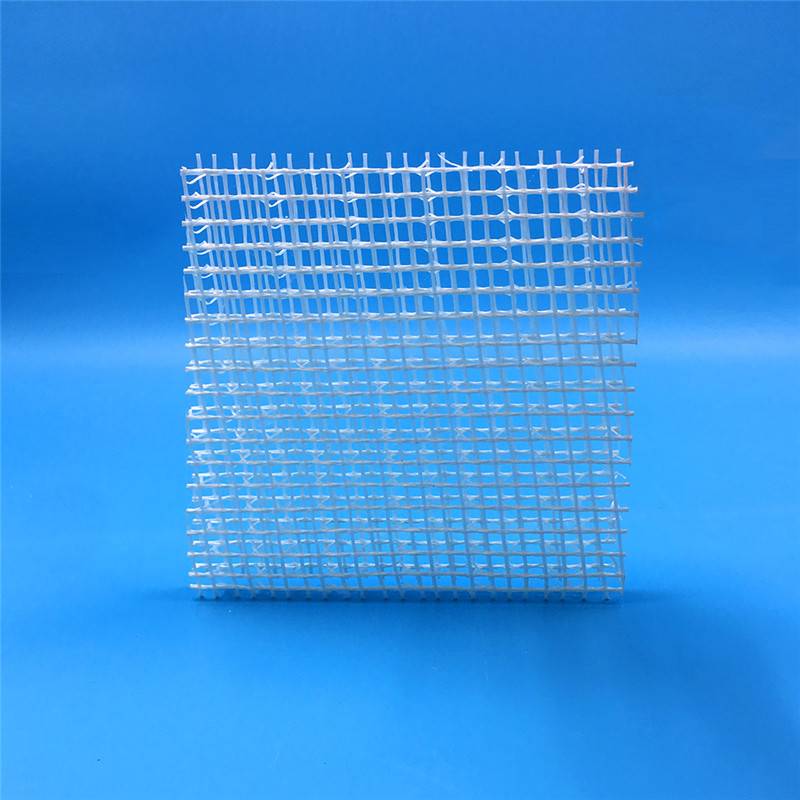

Assembled Panel Roving is coated with a silane-based sizing compatible with UP. It can wet out fast in resin and deliver excellent dispersion after chopping.

Features

●Light weight

●High strength

●Excellent impact resistance

●No white fiber

●High translucency

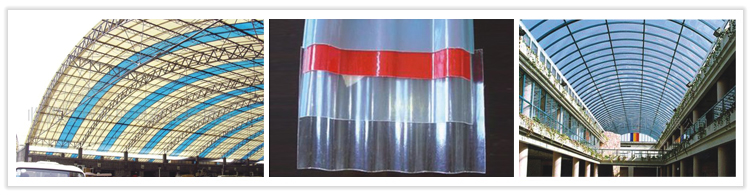

Application

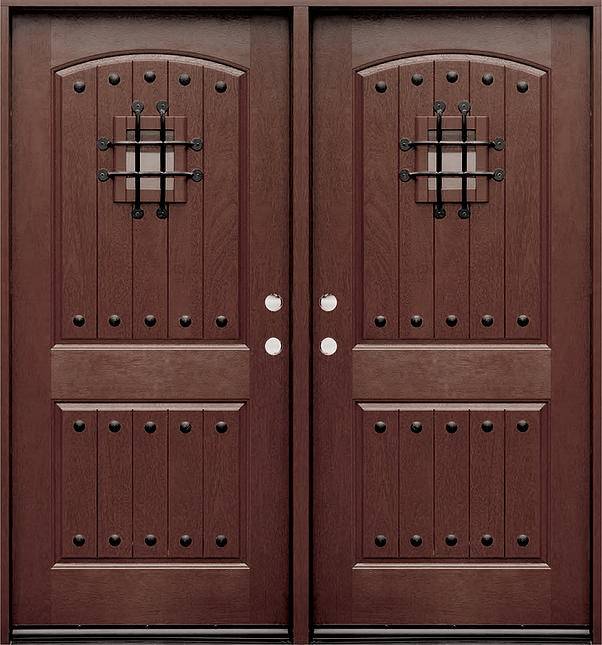

It can be used to manufacture lighting boards in building & construction industry.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHP-01A |

2400, 4800 |

UP |

low static, moderate wet out, excellent dispersion |

translucent and opaque panels |

|

BHP-02A |

2400, 4800 |

UP |

extremely fast wet-out, superior transparency |

high transparency panel |

|

BHP-03A |

2400, 4800 |

UP |

low static, fast wet out, no white fiber |

general purpose |

|

BHP-04A |

2400 |

UP |

good dispersion, good anti-static property, excellent wet-out |

transparent panels |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

12, 13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.15 |

0.60±0.15 |

115±20 |

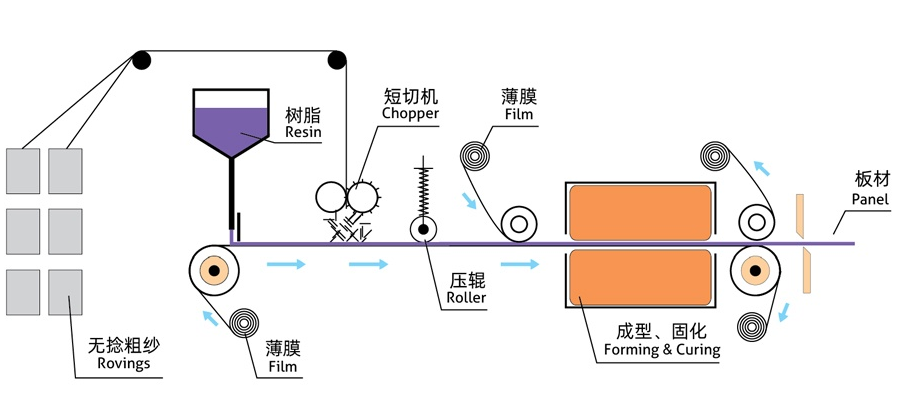

Continuous Panel Moulding process

A resin mix is uniformly deposited in a controlled amount onto the moving film at the constant speed . The thickness of the resin is controlled by the draw-knife . The fiberglass roving is chopped and uniformly distributed onto the resin, then a top film is applied forming a sandwich structure . The wet assembly travels through the curing oven to form the composite panel.

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Low price for End To End Fiberglass Smc Roving - E-glass Assembled Panel Roving – Beihai Fiberglass , The product will supply to all over the world, such as: Chile, Rwanda, Honduras, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.