High Quality Thermal Insulation Aerogel Blanket Felt Building Insulation Fireproof Aerogel Silica Blanket

Product Introduction

Aerogel is a kind of solid material with excellent thermal insulation performance, with high specific surface area, nano-level pores, low density and other special microstructure, it is called “the magic material that changes the world”, also known as “the ultimate thermal insulation material”, is the lightest solid material. Aerogel has a three-dimensional nano-network porous structure, with low density, high specific surface area, high porosity, low dielectric constant, low thermal conductivity and other physical properties, and has a wide range of application prospects in the fields of thermal insulation, fire retardant, sound insulation, noise reduction, optics, electricity and so on.

Performance characteristics

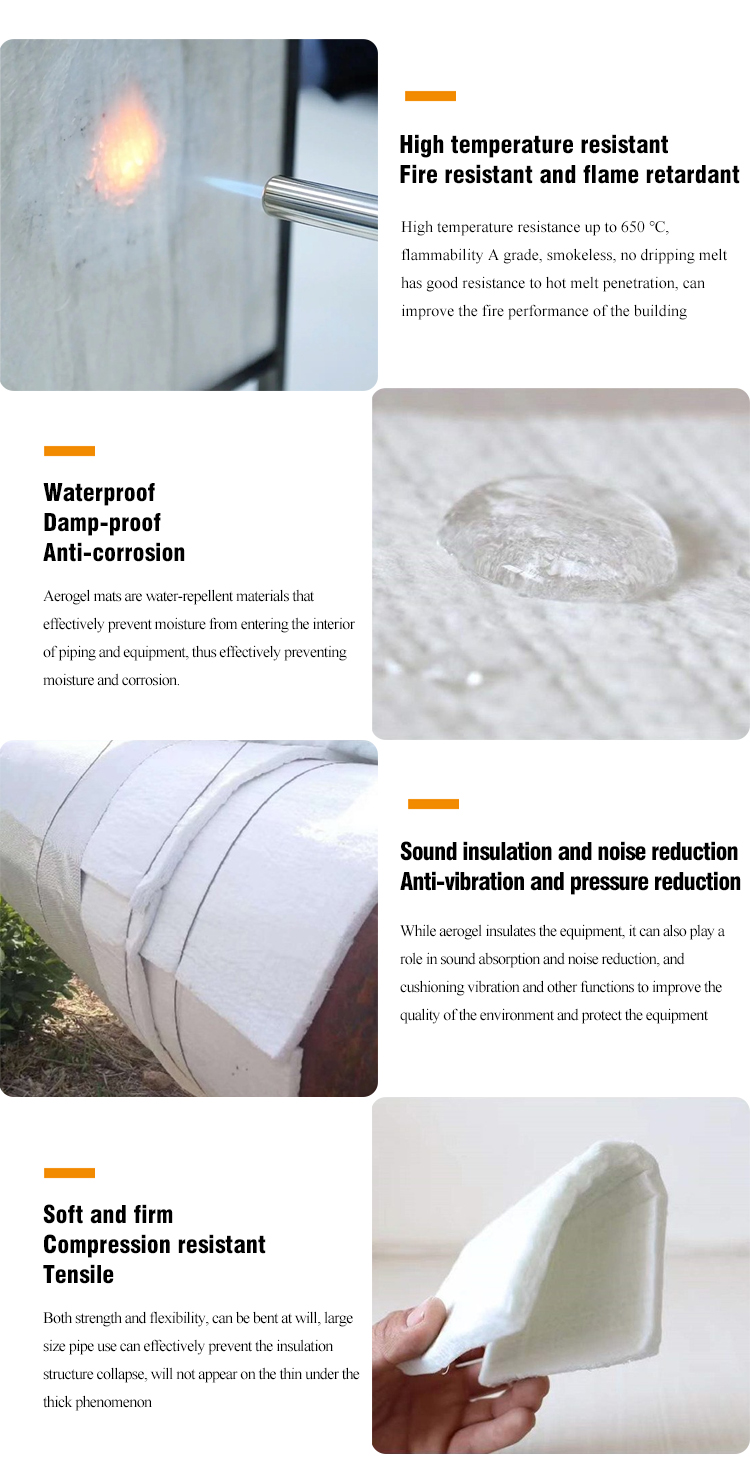

1、Heat insulation and high temperature resistance

Low thermal conductivity, conventional products thermal conductivity 0.018~0.020 W/(m-K), as low as 0.014 W/(m-K), each temperature section is lower than the peer products, the highest can withstand 1100 ℃ high temperature, thermal insulation effect for the traditional materials 3-5 times, high efficiency and energy saving.

2、Waterproof and breathable

With excellent overall waterproof performance, water repellency rate ≥99%, isolating liquid water, while allowing water vapor to pass through.

3、Fireproof and non-combustible

In the building combustion grade standards to achieve the highest level of A1, in the car interior material combustion grade also reached the highest level of A non-combustible.

4、Safety and environmental protection

The products have passed RoHS and REACH tests, and do not contain harmful substances to human body, and the content of soluble chloride ions is very small.

5、Tensile and compression resistance, convenient construction and transportation

Good flexibility and tensile/compressive strength, no settlement and deformation in long-term use; light and convenient, easy to cut, high construction efficiency, suitable for a variety of complex shape requirements, low transportation costs.

Specification Model

According to the different selection of base material, aerogel mat can choose different composite series according to different needs and scenarios of customers. At present, there are mainly four series of glass fiber composite aerogel (HHA-GZ), pre-oxygenated fiber composite aerogel (HHA-YYZ), high silica oxygen fiber composite aerogel (HHA-HGZ) and ceramic fiber composite aerogel (HHA-TCZ).

The specification parameters are as follows:

|

Product Model |

Specification size |

Thermal conductivity (W/(m·K)) |

Operating temperature (℃) |

Density (kg/m3) |

Water repellency (%) |

Fire Rating |

Tensile strength (MPa) |

||

|

thick(mm) |

wide(m) |

Long(m) |

|||||||

|

BHA-GZ |

3~20 Customizable |

1.5 Customizable |

Customizable |

<0.021 |

≤650 |

160~180 |

≥99 |

A1 |

≥1.2 |

|

BHA-YYZ |

1~10 Customizable |

1.5 Customizable |

Customizable |

<0.021 |

≤550 |

160~180 |

≥99 |

A2 |

≥1.2 |

|

BHA-HGZ |

3~20 Customizable |

1.5 Customizable |

Customizable |

<0.021 |

≤850 |

160~180 |

≥99 |

A1 |

≥1.2 |

|

BHA-TCZ |

5~10 Customizable |

1.5 Customizable |

Customizable |

<0.021 |

≤950 |

160~200 |

≥99 |

A1 |

≥0.3 |