High Performance E Glass Plain Weave Reinforce 100G Fiber Glass Roll 4Oz Fiberglass Fabric For Boats Surfboards

Products Introduction

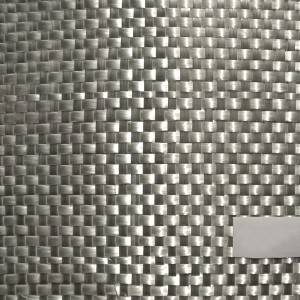

Glass cloth is generally divided into two categories: alkali-free and medium alkali. Alkali-free glass cloth is mainly used for the production of various electrical insulation laminates, printed circuit boards, various vehicle bodies, storage tanks, boats, molds, etc. Medium alkali glass cloth is mainly used for the production of plastic coated packaging cloth, as well as for corrosion resistant occasions, thickened satin glass fiber cloth can be made into fire blankets, welding blankets, fire blankets, fire curtains and other products.

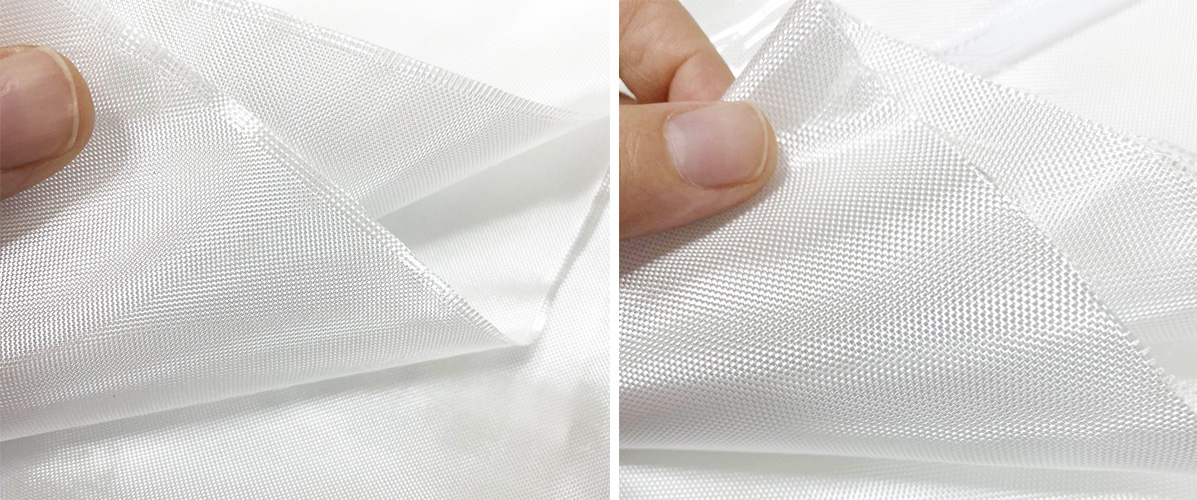

The characteristics of the fabric are determined by the fiber properties, warp and weft density, yarn structure and weave pattern. Warp and weft density is in turn determined by yarn structure and weave pattern. The warp and weft density plus the yarn structure determine the physical properties of the fabric, such as weight, thickness and breaking strength. There are three basic weave patterns: plain plan (similar to chevron), twill (generally +-45 degrees), and satin statin (similar to one-way fabric).

Woven more dilute glass wire cloth is mainly used for pipeline corrosion, insulation, flue {exhaust duct}, European, lightweight wall panels, sandstone murals, fiberglass products and a series of cement gypsum and other GRC components and insulation panels composite panels movable panels and walls, etc..

Performance: anti-corrosion, buried in the ground will not decay, erected in the air will not be weathered, not afraid of water, not afraid of sun.

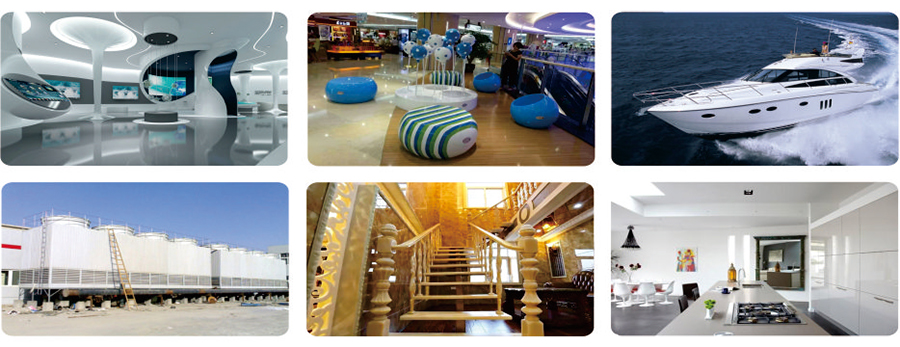

Product Applications

Widely used in FRP products, handicraft products, ships, car shells, cold water towers, indoor ornaments, outdoor large sculpture crafts, imitation jade, marble, granite and electronic machinery anti-corrosion and acid and alkali resistance.