High definition Fiberglass Direct Roving - E-glass Assembled Roving For Spray up – Beihai Fiberglass

High definition Fiberglass Direct Roving - E-glass Assembled Roving For Spray up – Beihai Fiberglass Detail:

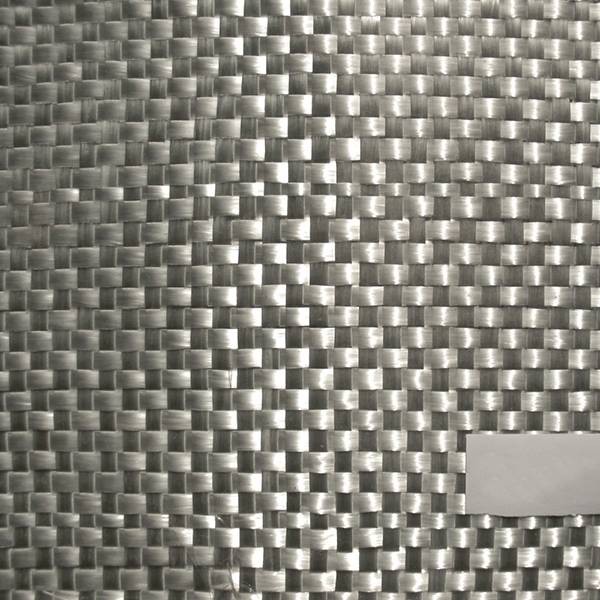

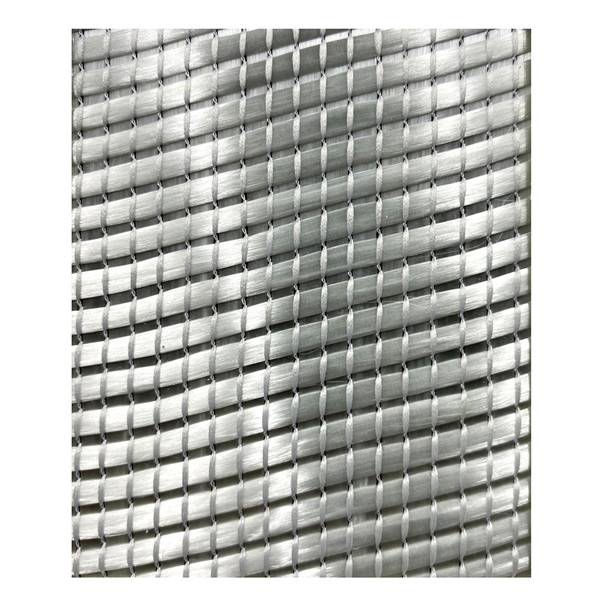

E-glass Assembled Roving For Spray up

Assembled Roving for spray-up is compatible with UP and VE resins. It delivers properties of low static, excellent dispersion, and good wet out in resins.

Features

●Low static

●Excellent dispersion

●Good wet-out in resins

Application

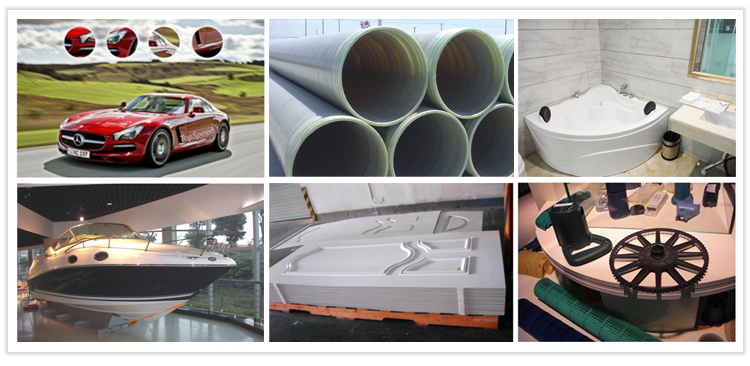

It covers a wide range of applications: bathtub, FRP boat hulls, various pipes, storage vessels and cooling towers.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHSU-01A |

2400, 4800 |

UP, VE |

fast wet out, easy roll-out, optimum dispersion |

bathtub, supporting components |

|

BHSU-02A |

2400, 4800 |

UP, VE |

easy roll-out, no spring-back |

bathroom equipment, yacht components |

|

BHSU-03A |

2400, 4800 |

UP, VE, PU |

fast wet out, excellent mechanical and water resistance property |

bathtub, FRP boat hull |

|

BHSU-04A |

2400, 4800 |

UP, VE |

moderate wet out speed |

swimming pool, bathtub |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

11, 12, 13 |

| Linear Density, tex |

2400, 3000 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.05±0.15 |

135±20 |

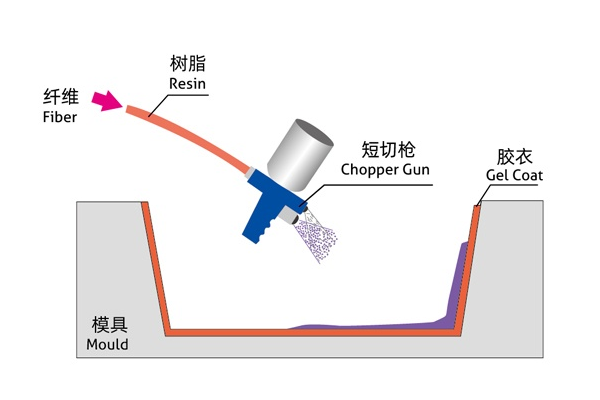

Spray-up Process

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving ( fiberglass cut to specific length using a chopper gun ) . Then the glass-resin mixture is well compacted , usually manually , for complete impregnation and deairing . After curing the finished composite part is de-molded

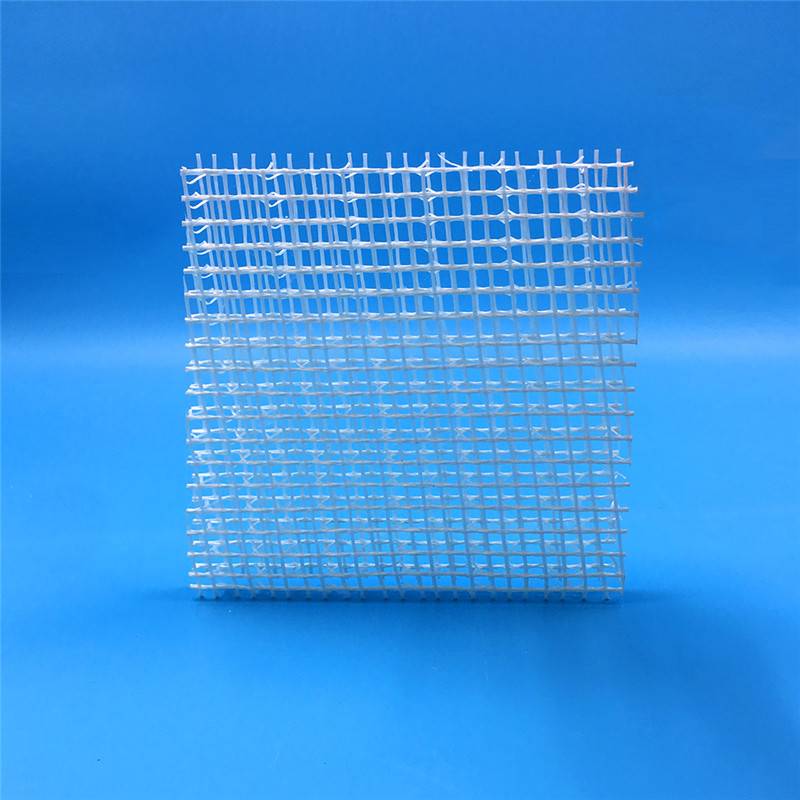

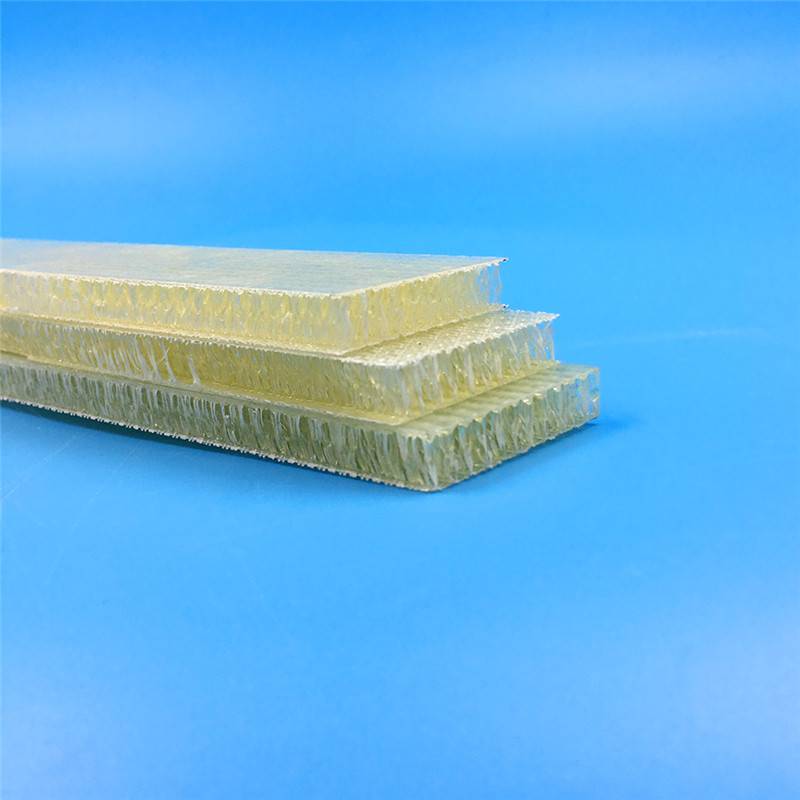

Product detail pictures:

Related Product Guide:

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of High definition Fiberglass Direct Roving - E-glass Assembled Roving For Spray up – Beihai Fiberglass , The product will supply to all over the world, such as: Nigeria, Sevilla, Manila, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!