Good Quality Tissue Mat - Fiberglass Surface Tissue Mat – Beihai Fiberglass

Good Quality Tissue Mat - Fiberglass Surface Tissue Mat – Beihai Fiberglass Detail:

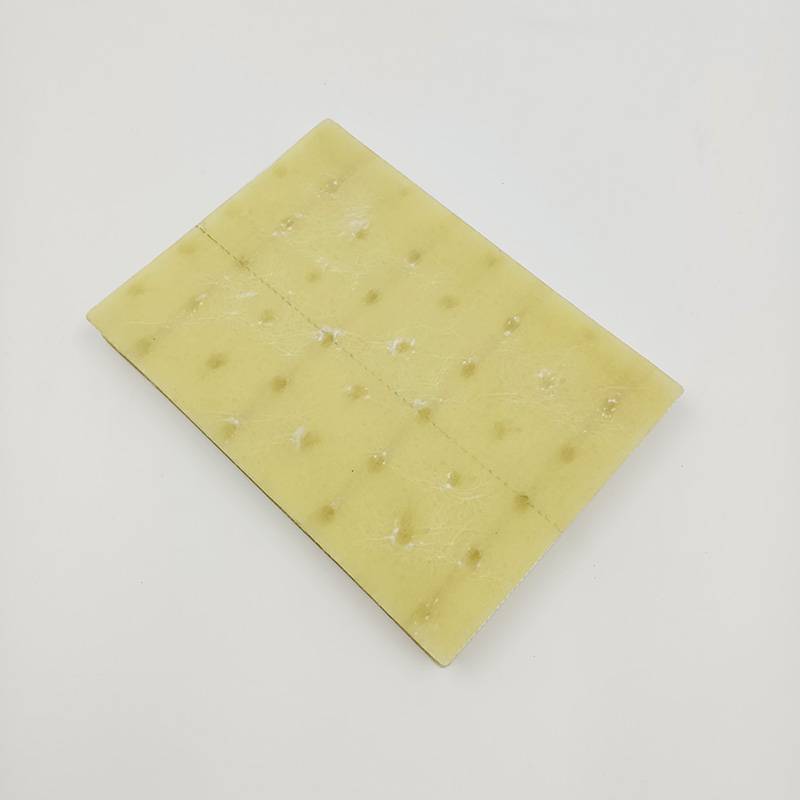

1.Fiberglass Surface Tissue Mat

Fiberglass Surface tissue mat is mainly used as the surface layers of FRP products. It is characterized by uniform fiber dispersion,smooth surface, soft hand-feeling, low binder content, fast resin impregnation and good mould obedience. This line of product falls into two catalogues: filament winding type CBM series and hand lay-up type SBM series .CBM surfacing mat is most suitable for warping FRP Pipes and vessels because it is capable of significantly improving the performances of surface layer to realize longer lifetime and resistance against corrosion, leakage and compression. SBM surfacing mat is suitable for moulding with sophisticated contours while it is characterized by its good mould obedience and fast resin saturating, it is indispensable materials for high quality moulds and FRP products as it is capable of covering up the texture of under layers to create high gloss surface that give rise to improved strength and corrosion resistance .the surfacing mats in these two categories are also applicable to other FRP moulding process such as press moulding spary-up, centrifugal rotaing moulding.

Features

Model and characteristic:

|

Item |

Unit |

Type |

|||||

|

|

|

BH-CBM20 |

BH-CBM30 |

BH-CBM50 |

BH-SBM30 |

BH-SBM40 |

BH-SBM50 |

|

Area Weight |

g/m2 |

20 |

30 |

50 |

30 |

40 |

50 |

|

Binder Content |

% |

7.0 |

6.0 |

6.0 |

7.0 |

6.0 |

6.0 |

|

Penetration(two layers) |

s |

<8 |

<10 |

<16 |

<10 |

<15 |

<20 |

|

Tensile Strength MD |

N/5cm |

≥20 |

≥25 |

≥40 |

≥20 |

≥25 |

30 |

|

Moisture Content |

% |

<0.2 |

<0.2 |

<0.2 |

<0.2 |

<0.2 |

<0.2 |

|

Standard Measurement Width X Length Roll Diameter Paper Core Internal Dia |

m×m cm cm |

1.0×1000 <100 15 |

1.0×1000 <100 15 |

1.0×1000 <100 15 |

1.0×1000 <100 15 |

1.0×1000 <100 15 |

1.0×1000 <100 15 |

Testing Standard:ISO3717

Application:

Its mainly used as the surface layers of FRP products.

Shipping & Storage

Unless otherwise specified, the Fiberglass products should be in dry, cool and moisture- proof area. The room temperature and humility should be always maintained at 15℃-35℃ and 35%-65% respectively.

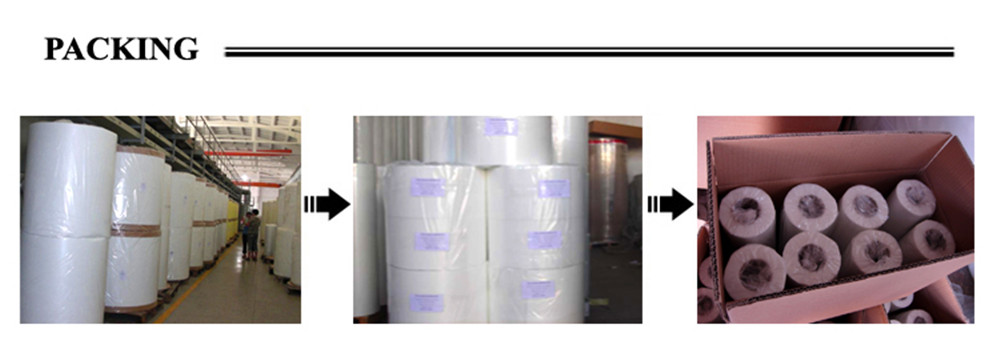

Packaging

The product can be packed in bulk bags, heavy-duty box and composite plastic woven bags.

Our Service

1.Your inquiry will be replied within 24hours

2.Well-trained and experienced staffs can answer your entire question fluently.

3.All our products have 1-year warranties if follow our guide

4.Specialized team makes us strong support to solve your problem from purchases to application

5.Competitive prices based on same quality as we are factory supplier

6.Guarantee samples quality same as the bulk production.

7.Positive attitude to custom design products.

Contact Details

1. Factory: CHINA BEIHAI FIBERGLASS CO.,LTD

2. Address: Beihai Industrial Park, 280# Changhong Rd., Jiujiang City, Jiangxi China

3. Email:sales@fiberglassfiber.com

4. Tel: +86 792 8322300/8322322/8322329

Cell: +86 13923881139(Mr Guo)

+86 18007928831(Mr Jack Yin)

Fax: +86 792 8322312

5. Online contacts:

Skype: cnbeihaicn

Whatsapp: +86-13923881139

+86-18007928831

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for Good Quality Tissue Mat - Fiberglass Surface Tissue Mat – Beihai Fiberglass , The product will supply to all over the world, such as: Chicago, Mauritius, Mombasa, We now have to continue to uphold the "quality, detailed, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!