FRP Panel

Product Description

FRP (also known as glass fiber reinforced plastic, abbreviated as GFRP or FRP) is a new functional material made of synthetic resin and glass fiber through a composite process.

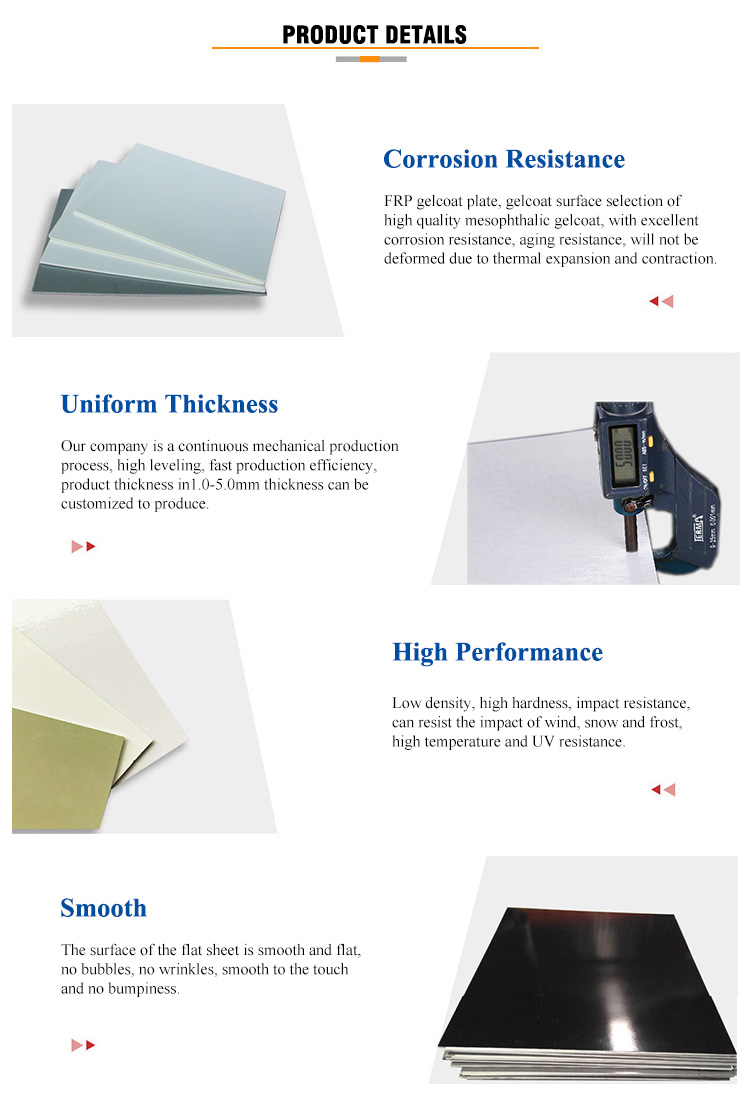

FRP sheet is a thermosetting polymer material with the following characteristics:

(1) light weight and high strength.

(2)Good corrosion resistance FRP is a good corrosion resistant material.

(3) Good electrical properties are excellent insulating materials, used to manufacture insulators.

(4)Good thermal properties FRP has low thermal conductivity.

(5)Good designability

(6)Excellent processability

Applications:

Widely used in buildings, freezing and refrigerating warehouses, refrigerating carriages, train carriages, bus carriages, boats, food processing workshops, restaurants, pharmaceutical plants, laboratories, hospitals, bathrooms, schools and other places such as walls, partitions, doors, suspended ceilings, etc.

| Performance | Unit | Pultruded Sheets | Pultruded Bars | Structural Steel | Aluminum | Rigid Polyvinyl chloride |

| Density | T/M3 | 1.83 | 1.87 | 7.8 | 2.7 | 1.4 |

| Tensile Strength | Mpa | 350-500 | 500-800 | 340-500 | 70-280 | 39-63 |

| Tensile modulus of elasticity | Gpa | 18-27 | 25-42 | 210 | 70 | 2.5-4.2 |

| Bending strength | Mpa | 300-500 | 500-800 | 340-450 | 70-280 | 56-105 |

| Flexural modulus of elasticity | Gpa | 9~16 | 25-42 | 210 | 70 | 2.5-4.2 |

| Coefficient of thermal expansion | 1/℃×105 | 0.6-0.8 | 0.6-0.8 | 1.1 | 2.1 | 7 |