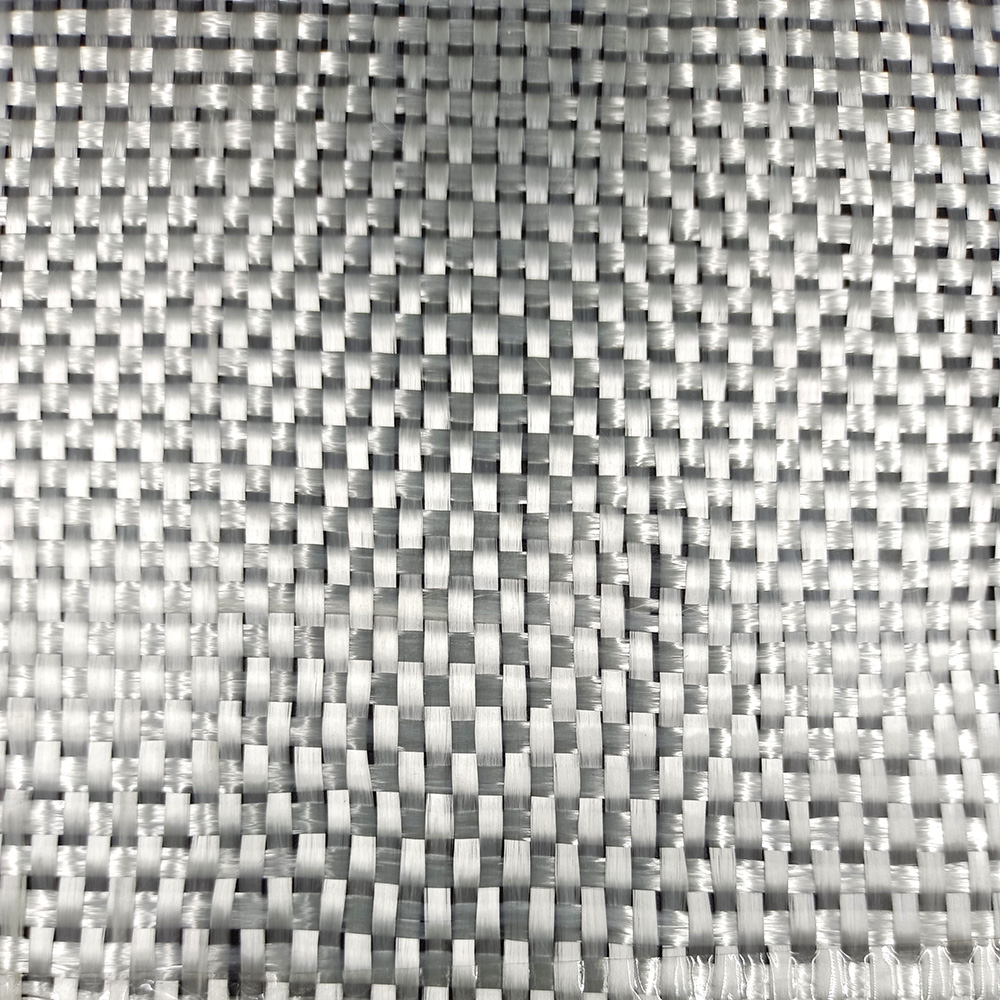

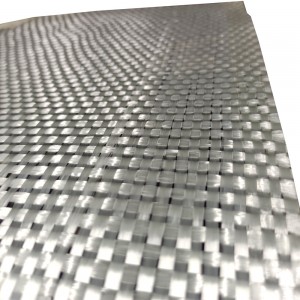

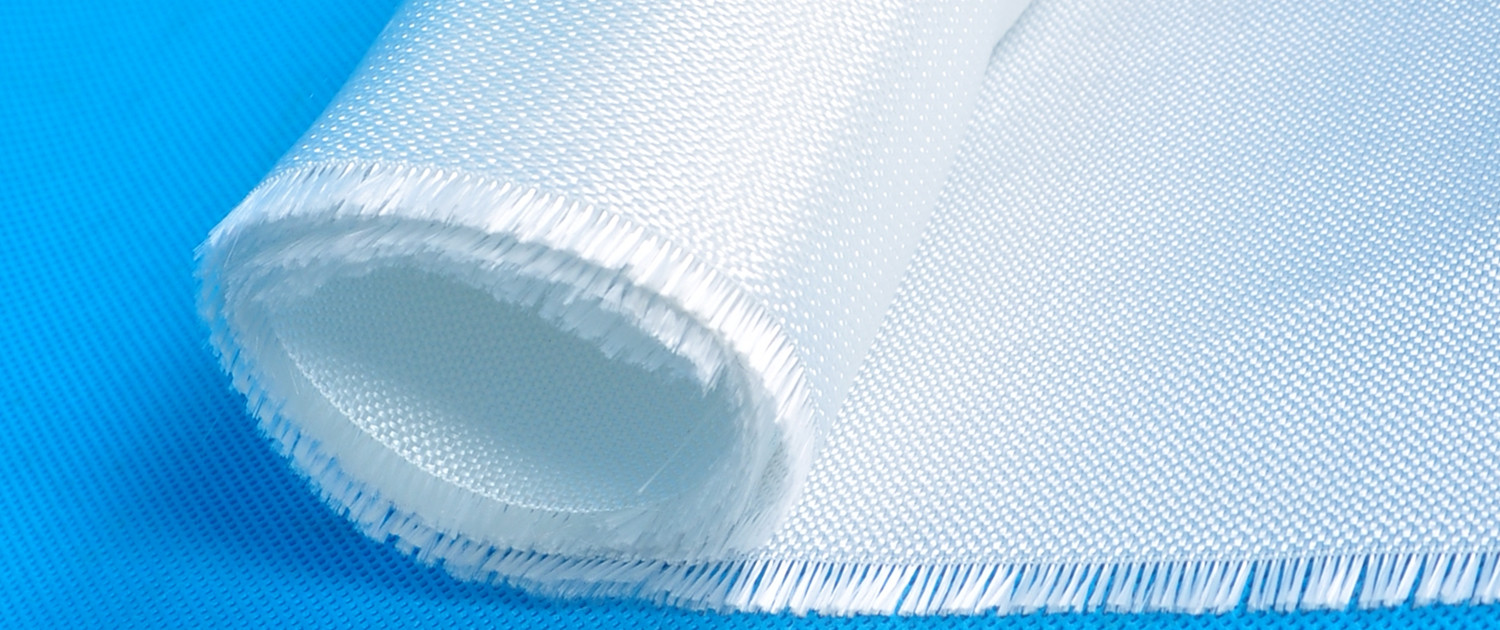

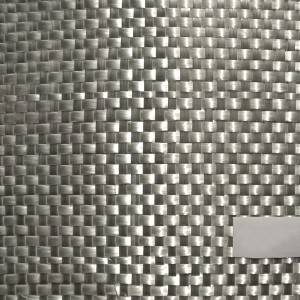

Fiberglass Woven Roving

Woven Roving Fiberglass cloth is a collection of specific numbers of untwisted continuous filaments. Due to higher fiber content, woven roving’s lamination has excellent tensile strength and impact-resistant property.

Woven roving is the primary strength material used in fiberglass boatbuilding. 24 oz. per square yard material wets out easily and is usually used between layers of mat for strong laminates. Woven Roving is made from continuous glass fiber roving which are interlaced into heavy weight fabrics. Used in most cases to increase the flexural and impact strength of laminates. Ideal for multi-layer hand lay-up applications where great material strength is required. Good drapeability, wet out and cost effective. With Woven Roving as a general rule estimate the resin/reinforcement ratio at 1:1 by weight. Marine Polyester Resin is the preferred resin for wetting out this form of glass fiber material. Application should be made on a dry tack-free surface. When using with Marine Resin, mix 8 drops Hardener per 1 ounce.