Fiberglass Reinforced Polymer Bars

Detailed Introduction

Fiber reinforced composites (FRP) in civil engineering applications in the significance of “structural durability problems and in some special working conditions to play its lightweight, high strength, anisotropic characteristics,” combined with the current level of application technology and market conditions, industry experts believe that its application is selective. In the subway shield cutting concrete structure, high-grade highway slopes and tunnel support, resistance to chemical erosion and other fields has shown excellent application performance, more and more accepted by the construction unit.

Product Specification

Nominal diameters range from 10mm to 36mm. Recommended nominal diameters for GFRP bars are 20mm, 22mm, 25mm, 28mm and 32mm.

| Project | GFRP Bars | Hollow grouting rod (OD/ID) | |||||||

| Performance/Model | BHZ18 | BHZ20 | BHZ22 | BHZ25 | BHZ28 | BHZ32 | BH25 | BH28 | BH32 |

| Diameter | 18 | 20 | 22 | 25 | 28 | 32 | 25/12 | 25/12 | 32/15 |

| The following technical indicators are not less than | |||||||||

| Rod body tensile strength (KN) | 140 | 157 | 200 | 270 | 307 | 401 | 200 | 251 | 313 |

| Tensile strength (MPa) | 550 | 550 | 550 | 550 | 500 | 500 | 550 | 500 | 500 |

| Shear strength (MPa) | 110 | 110 | |||||||

| Modulus of elasticity (GPa) | 40 | 20 | |||||||

| Ultimate tensile strain (%) | 1.2 | 1.2 | |||||||

| Nut tensile strength (KN) | 70 | 75 | 80 | 90 | 100 | 100 | 70 | 100 | 100 |

| Pallet carrying capacity (KN) | 70 | 75 | 80 | 90 | 100 | 100 | 90 | 100 | 100 |

Remarks: Other requirements should comply with the provisions of the industry standard JG/T406-2013 “Glass Fiber Reinforced Plastic for Civil Engineering”

Application Technology

1. Geotechnical engineering with GFRP anchor support technology

Tunnel, slope and subway projects will involve geotechnical anchoring, anchoring often use high tensile strength steel as anchor rods, GFRP bar in the long-term poor geological conditions have good corrosion resistance, GFRP bar instead of steel anchor rods with no need for corrosion treatment, high tensile strength, light weight and easy to manufacture, transportation and installation advantages, at present, GFRP bar is being increasingly used as anchor rods for geotechnical projects. Currently, GFRP bars are being used more and more as anchor rods in geotechnical engineering.

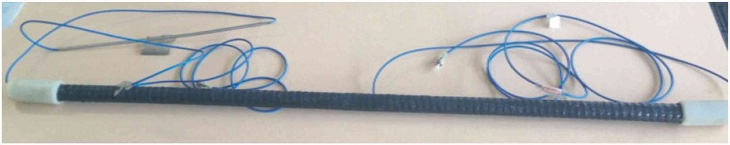

2. Self-inductive GFRP bar intelligent monitoring technology

Fiber grating sensors have many unique advantages over traditional force sensors, such as simple structure of the sensing head, small size, light weight, good repeatability, anti-electromagnetic interference, high sensitivity, variable shape and the ability to be implanted into the GFRP bar in the production process. LU-VE GFRP Smart Bar is a combination of LU-VE GFRP bars and fiber grating sensors, with good durability, excellent deployment survival rate and sensitive strain transfer characteristics, suitable for civil engineering and other fields, as well as construction and service under harsh environmental conditions.

3. Shield cuttable concrete reinforcement technology

In order to block the infiltration of water or soil under the action of water pressure due to the artificial removal of steel reinforcement in concrete in the subway enclosure structure, outside the water-stopping wall, the workers must fill some dense soil or even plain concrete. Such operation undoubtedly increases the labor intensity of workers and the cycle time of underground tunnel excavation. The solution is to use GFRP bar cage instead of steel cage, which can be used in the concrete structure of subway end enclosure, not only the bearing capacity can meet the requirements, but also due to the fact that the GFRP bar concrete structure has the advantage that it can be cut in the shield machine (TBMs) traversing the enclosure, greatly eliminating the need for the workers to go in and out of the working shafts frequently, which can accelerate the speed of the construction and the safety.

4. GFRP bar ETC lane application technology

Existing ETC lanes exist in the loss of passage information, and even repeated deduction, neighboring road interference, repeated uploading of transaction information and transaction failure, etc., the use of non-magnetic and non-conductive GFRP bars instead of steel in the pavement can slow down this phenomenon.

5. GFRP bar continuous reinforced concrete pavement

Continuously reinforced concrete pavement (CRCP) with comfortable driving, high bearing capacity, durable, easy maintenance and other significant advantages, the use of glass fiber reinforcing bars (GFRP) instead of steel applied to this pavement structure, both to overcome the disadvantages of easy corrosion of steel, but also to maintain the advantages of continuously reinforced concrete pavement, but also reduce the stress within the pavement structure.

6. Fall and winter GFRP bar anti-CI concrete application technology

Due to the common phenomenon of road icing in winter, salt de-icing is one of the more economical and effective way, and chloride ions are the main culprits of corrosion of reinforcing steel in reinforced concrete pavement. The use of excellent corrosion resistance of GFRP bars instead of steel, can increase the life of the pavement.

7. GFRP bar marine concrete reinforcement technology

Chloride corrosion of steel reinforcement is the most fundamental factor affecting the durability of reinforced concrete structures in offshore projects. The large-span girder-slab structure often used in harbor terminals, due to its self-weight and the large load it bears, is subjected to huge bending moments and shear forces in the span of the longitudinal girder and at the support, which in turn causes cracks to develop. Due to the action of seawater, these localized reinforcement bars can be corroded in a very short period of time, resulting in a reduction of the bearing capacity of the overall structure, which affects the normal use of the wharf or even the occurrence of safety accidents.

Application scope:seawall, waterfront building structure, aquaculture pond, artificial reef, water break structure, floating dock

etc.

8. Other special applications of GFRP bars

(1)Anti-electromagnetic interference special application

Airport and military facilities anti-radar interference devices, sensitive military equipment testing facilities, concrete walls, health care unit MRI equipment, geomagnetic observatory, nuclear fusion buildings, airport command towers, etc., can be used instead of steel bars, copper bars, etc. GFRP bars as the reinforcing material for concrete.

(2) Sandwich wall panel connectors

The precast sandwich insulated wall panel is composed of two concrete side panels and an insulating layer in the center. The structure adopts the newly introduced OP-SW300 glass fiber reinforced composite material (GFRP) connectors through the thermal insulation board to connect the two concrete side panels together, making the thermal insulation wall completely eliminate cold bridges in the construction. This product not only utilizes the non-thermal conductivity of LU-VE GFRP tendons, but also gives full play to the combination effect of the sandwich wall.