Fiberglass felt is used in aerogel felt base fabric and high temperature filter bag

Fiberglass is an inorganic non-metallic material with excellent performance. There are many kinds.The advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength.

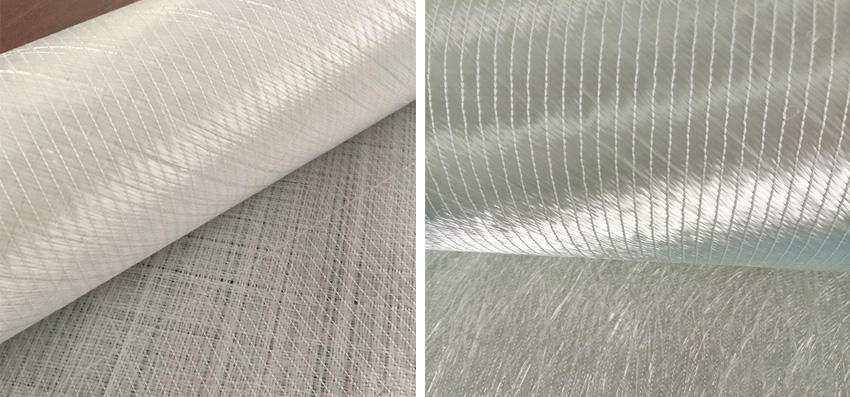

Fiberglass can be made into fiberglass needle felt through needle punched non-woven equipment. The general fiberglass felt can be used as the base cloth of high temperature filter bag or the base cloth of aerogel felt.

The fiberglass filter bag needle-punched felt uses the needle-punching method to compound the fiberglass fabric. It is an ideal filter material with high temperature resistance, medium temperature, low temperature and high humidity. It can be sewn into filter bags of various specifications.

It can be used for a long time at a high temperature of 240 °C, and the temperature resistance can reach 280 °C in a short time. It is widely used in high temperature flue gas filtration in steel, cement, electricity, non-ferrous metals, waste incineration, asphalt concrete mixing, chemical industry and other industries. It is suitable for pulse and high-speed reaction. The blowing dust removal method is the most widely used filter material for high temperature bag filter.

Aerogel, also known as air glue, solid smoke or blue smoke, is a super thermal insulation material with a nanoporous network structure. Sexual alternative products, with the lowest density of solids, the lowest thermal conductivity, the highest acoustic impedance, etc.

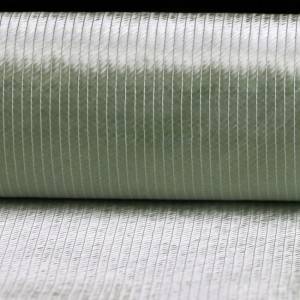

Nano-aerogel insulation felt is a kind of flexible aerogel insulation felt that combines aerogel into flexible substrate through a special process. Suitable for high temperature applications up to 650°C. The thermal insulation performance is more than 5 times that of traditional thermal insulation products, Class A (smokeless), non-combustible, environmentally friendly, flexible and easy to install.

Wider and higher operating temperature range

-200°C~+650°C, excellent performance in hot and humid environment up to 650ºC.

The thermal insulation performance is 5 times that of traditional thermal insulation products

Low thermal conductivity, at room temperature: about 0.02 w/(m*k), even lower than air thermal conductivity.

More and wider space utilization

Due to the low thermal conductivity, the same thermal insulation effect can be achieved with a thinner thermal insulation thickness, and the general installation thickness is about 80% thinner than that of traditional thermal insulation products.

Non-combustible (smokeless), Class A

The combustion performance grade meets the requirements of the combustion performance grade specified in GB8624-2012, and is class A fireproof.

Write your message here and send it to us