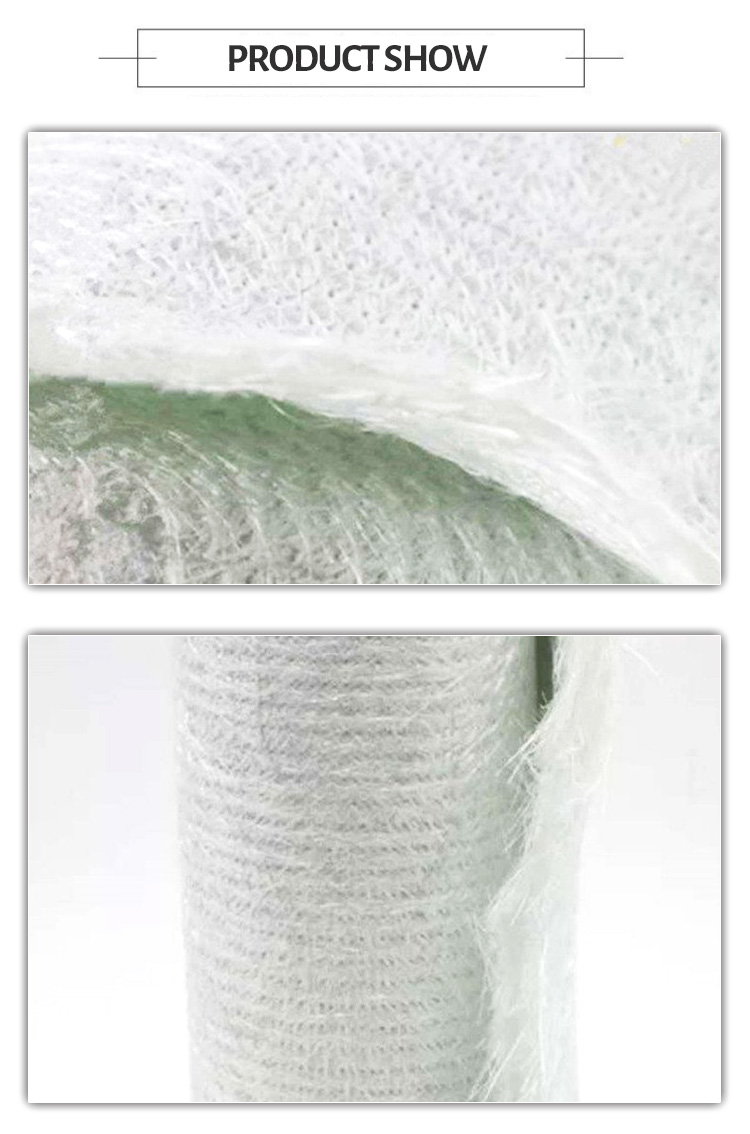

Fiberglass Core Mat

Product Description:

Core Mat is a new material, consisting of a synthetic non-woven core,sandwiched between two layers of chopped glass fibers or one layer of chopped glas fibers and the other one layer of multiaxial fabric/woven roving. Mainly used for RTM, Vacuum Forming, Molding, Injection Molding and SRIM Molding process, applied to FRP boat, automobile, aeroplane, panel, etc.

Product Specifications:

| Specifcation | Total weight (gsm) |

Deviation (%) |

0 degree (gsm) |

90 degree (gsm) | CSM (gsm) |

Core (gsm) |

CSM (gsm) |

Stitching Yarn (gsm) |

| BH-CS150/130/150 | 440 | ±7 | - | - | 150 | 130 | 150 | 10 |

| BH-CS300/180/300 | 790 | ±7 | - | - | 300 | 180 | 300 | 10 |

| BH-CS450/180/450 | 1090 | ±7 | - | - | 450 | 180 | 450 | 10 |

| BH-CS600/250/600 | 1460 | +7 | - | - | 600 | 250 | 600 | 10 |

| BH-CS1100/200/1100 | 2410 | ±7 | - | - | 1100 | 200 | 1100 | 10 |

| BH-300/L1/300 | 710 | ±7 | - | - | 300 | 100 | 300 | 10 |

| BH-450/L1/450 | 1010 | ±7 | - | - | 450 | 100 | 450 | 10 |

| BH-600/L2/600 | 1410 | ±7 | - | - | 600 | 200 | 600 | 10 |

| BH-LT600/180/300 | 1090 | ±7 | 336 | 264 | 180 | 300 | 10 | |

| BH-LT600/180/600 | 1390 | ±7 | 336 | 264 | 180 | 600 | 10 |

Remark: XT1 refers to one layer of flow mesh, XT2 refers to 2 layers of flow mesh. Besides the above regular specifications, more layers (4-5 Iayers) and other core materials can be combined according to the customer’s request.

Such as woven roving/multiaxial fabrics+core+chopped layer (single/double sides).

Product Features:

1. Sandwich construction can increase the strength and thickness of the product;

2. high permeabiity of thesynthetic core,good wet-outin resins,fast solidifying speed;

3. high mechanical performance,easy to operate;

4. easy toform in angles and morecomplex shapes;

5. core resilience and compressibility,to adaptto the different thickness of parts;

6. lack of chemical binder for a good impregnation of the reinforcement.

Product Application:

Widely used in winding molding to make FRP sand sandwiched pipes (pipe jacking), FRP ship hulls, wind turbine blades, annular reinforcement of bridges, transverse reinforcement of pultruded profiles, and sports equipment, etc. in the industry.