Factory Supply Fiberglass Panel Roving - E-glass Assembled Roving For GMT – Beihai Fiberglass

Factory Supply Fiberglass Panel Roving - E-glass Assembled Roving For GMT – Beihai Fiberglass Detail:

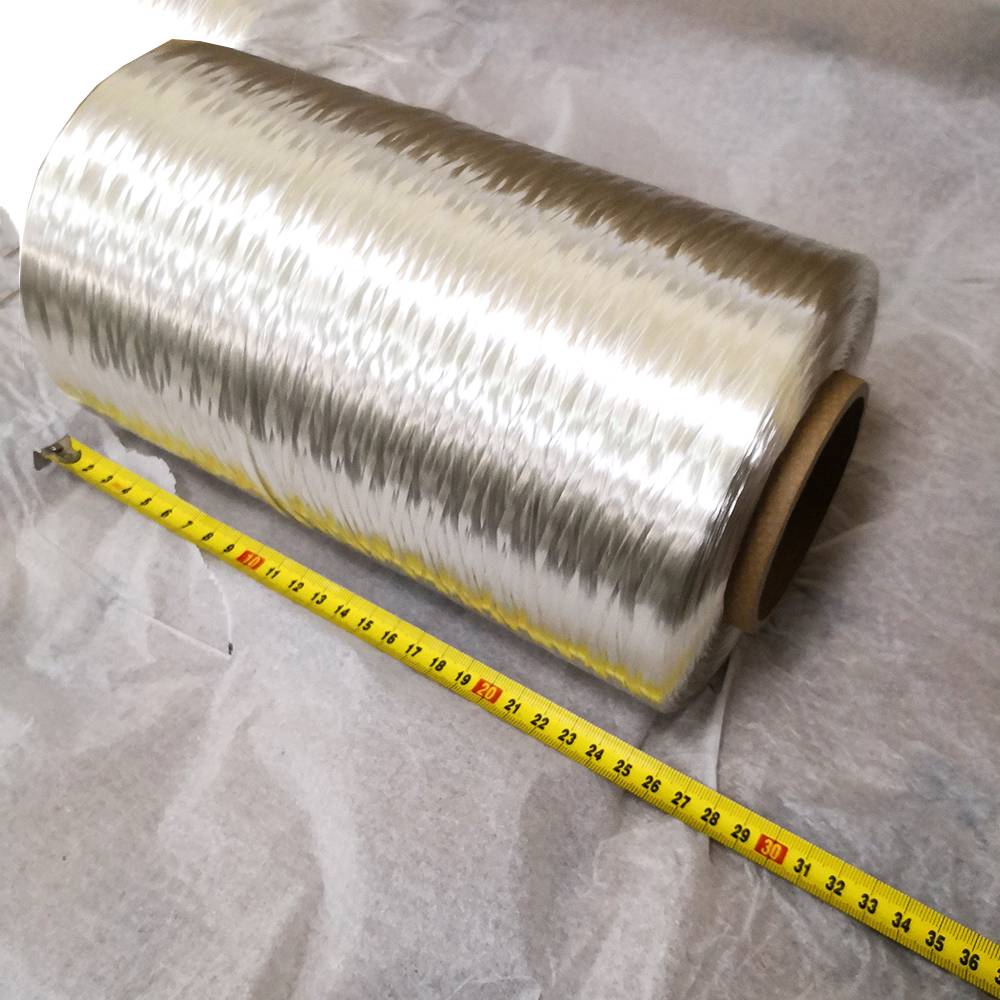

E-glass Assembled Roving For Spray up

Assembled Roving for spray-up is compatible with UP and VE resins. It delivers properties of low static, excellent dispersion, and good wet out in resins.

Features

●Low static

●Excellent dispersion

●Good wet-out in resins

Application

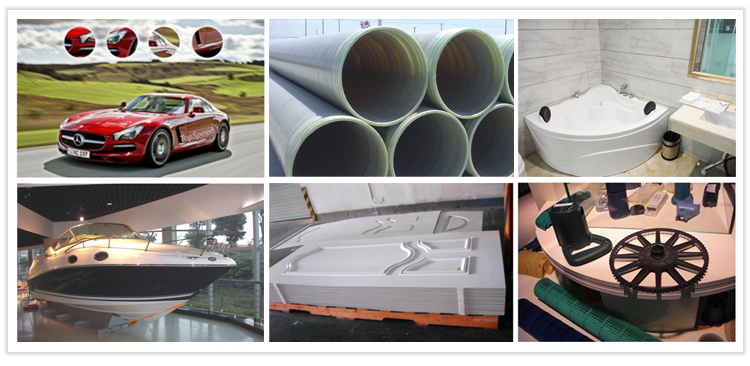

It covers a wide range of applications: bathtub, FRP boat hulls, various pipes, storage vessels and cooling towers.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHSU-01A |

2400, 4800 |

UP, VE |

fast wet out, easy roll-out, optimum dispersion |

bathtub, supporting components |

|

BHSU-02A |

2400, 4800 |

UP, VE |

easy roll-out, no spring-back |

bathroom equipment, yacht components |

|

BHSU-03A |

2400, 4800 |

UP, VE, PU |

fast wet out, excellent mechanical and water resistance property |

bathtub, FRP boat hull |

|

BHSU-04A |

2400, 4800 |

UP, VE |

moderate wet out speed |

swimming pool, bathtub |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

11, 12, 13 |

| Linear Density, tex |

2400, 3000 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.05±0.15 |

135±20 |

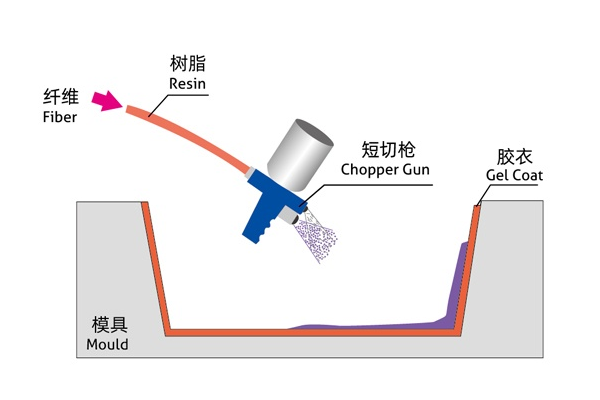

Spray-up Process

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving ( fiberglass cut to specific length using a chopper gun ) . Then the glass-resin mixture is well compacted , usually manually , for complete impregnation and deairing . After curing the finished composite part is de-molded

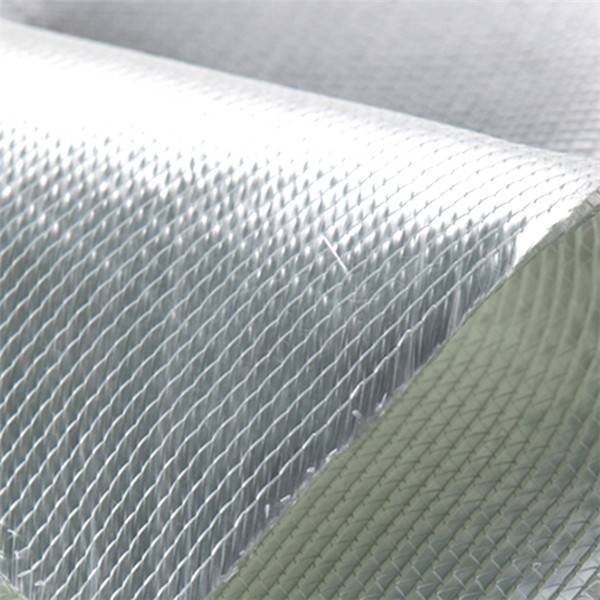

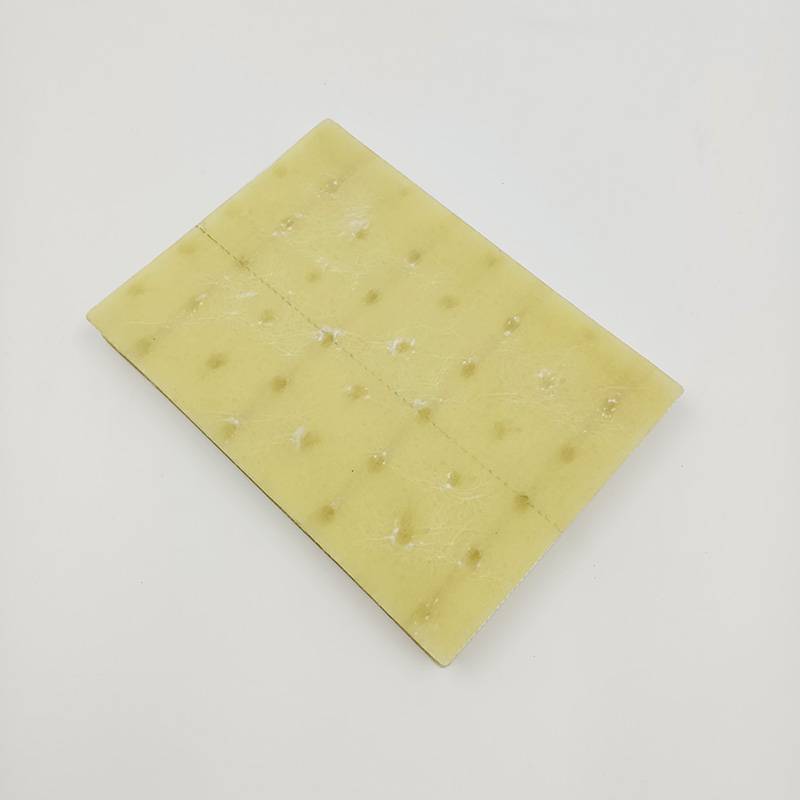

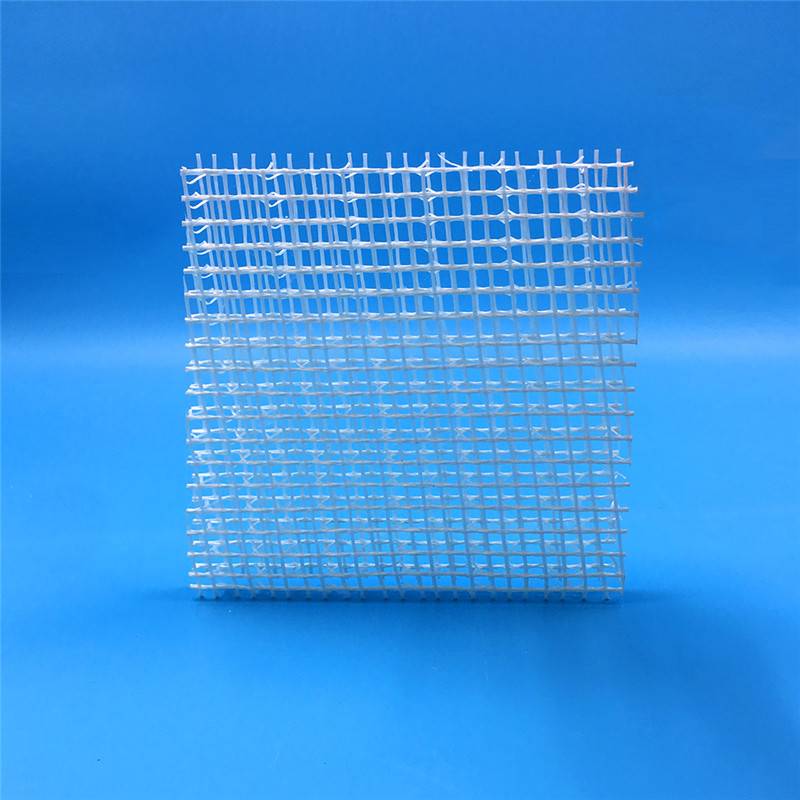

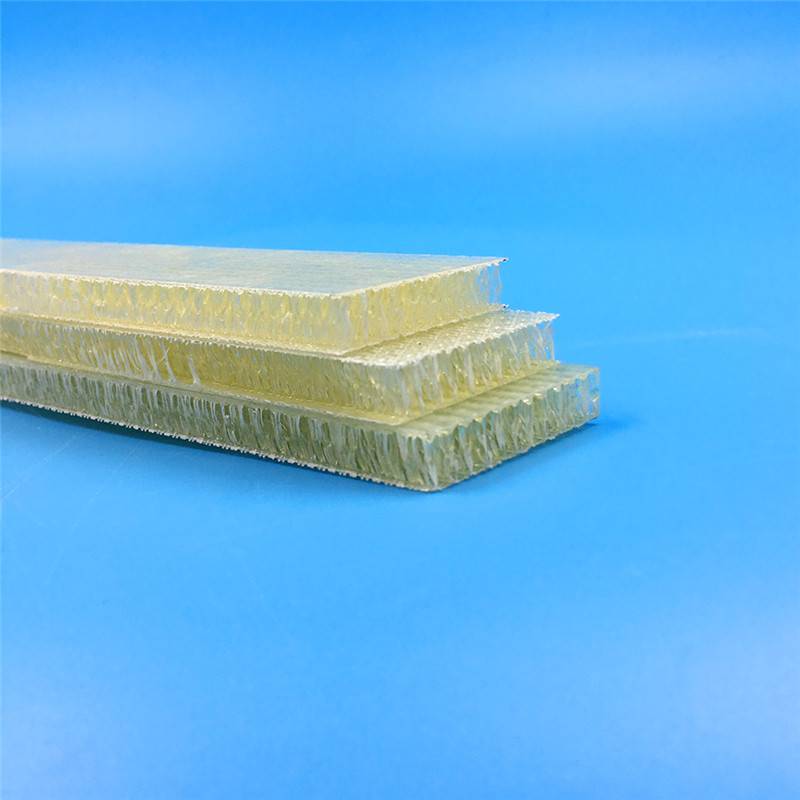

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for Factory Supply Fiberglass Panel Roving - E-glass Assembled Roving For GMT – Beihai Fiberglass , The product will supply to all over the world, such as: Cyprus, Egypt, Los Angeles, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.