ECR 600tex 1200tex 2400tex 4800tex Assembled Roving Gun Fiberglass Roving for Spray up Roving/ Injection / Pipe / Panel / SMC / LFT / Pultrusion / Filament Wind

Assembled Roving for spray-up is compatible with UP and VE resins. It delivers properties of low static, excellent dispersion, and good wet out in resins.

Features

l Low static

l Excellent dispersion

l Good wet-out in resins

Application

It covers a wide range of applications: bathtub, FRP boat hulls, various pipes, storage vessels and cooling towers.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHSU-01A |

2400, 4800 |

UP, VE |

fast wet out, easy roll-out, optimum dispersion |

bathtub, supporting components |

|

BHSU-02A |

2400, 4800 |

UP, VE |

easy roll-out, no spring-back |

bathroom equipment, yacht components |

|

BHSU-03A |

2400, 4800 |

UP, VE, PU |

fast wet out, excellent mechanical and water resistance property |

bathtub, FRP boat hull |

|

BHSU-04A |

2400, 4800 |

UP, VE |

moderate wet out speed |

swimming pool, bathtub |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

11, 12, 13 |

| Linear Density, tex |

2400, 3000 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.05±0.15 |

135±20 |

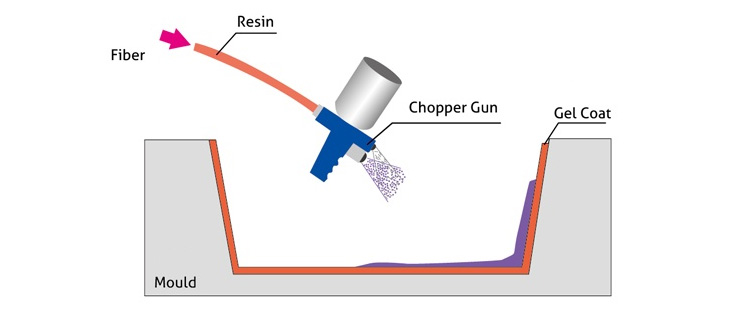

Spray-up Process

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving ( fiberglass cut to specific length using a chopper gun ) . Then the glass-resin mixture is well compacted , usually manually , for complete impregnation and deairing . After curing the finished composite part is de-molded