Direct Roving For LFT

Direct Roving For LFT

Direct Roving for LFT is coated with a silane-based sizing compatible with PA, PBT, PET, PP, ABS, PPS and POM resins.

Features

●Low fuzz

●Excellent compatibility with a multiple thermoplastic resin

●Good processing property

●Excellent mechanical property of the final composite product

Application

It is widely used in automotive,construction,sports,electric and electronic applications

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

| BHLFT-01D | 400-2400 | PP | Good integrity | excellent processing and mechanical property, extinct light color |

| BHLFT-02D | 400-2400 | PA,TPU | Low fuzz | excellent processing and mechanical property, designed for LFT-G process |

| BHLFT-03D | 400-3000 | PP | Good dispersion | specially designed for LFT-D process and widely used in automotive,construction,sports,electric and electronic applications |

| Identification | |||||

| Type of Glass |

E |

||||

| Direct Roving |

R |

||||

| Filament Diameter, μm | 400 | 600 | 1200 | 2400 | 3000 |

| Linear Density, tex | 16 | 14 | 17 | 17 | 19 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/Tex) |

|

ISO1889 |

ISO3344 |

ISO1887 |

IS03341 |

|

±5 |

≤0.10 |

0.55±0.15 |

≥0.3 |

LFT Process

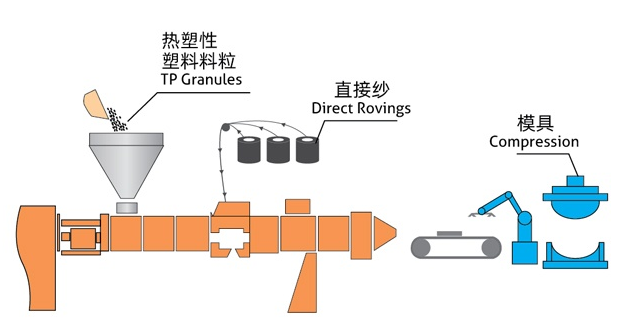

LFT-D Polymer pellets and glass roving are all introduced into atwin - screw extruder where the polymer is melted and compoundis formed . Then the molten compound is directly molded into the final parts by injection or compression molding process.

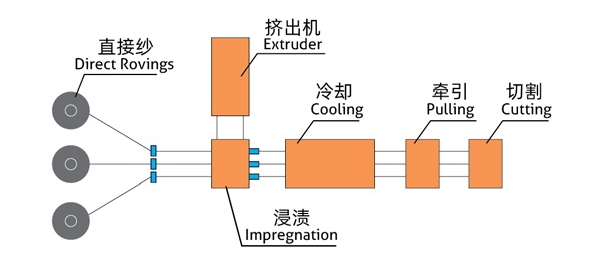

LFT-G The thermoplastic polymer is heated to a molten phase and pumped into the die-head The continuous roving is pulled through a dispersion died to ensure the glass fiber and polymer impregrated fully and to get consolidated rods . After cooling,The rod is chopped into reinforced pellets.