Direct Roving For CFRT

Direct Roving For CFRT

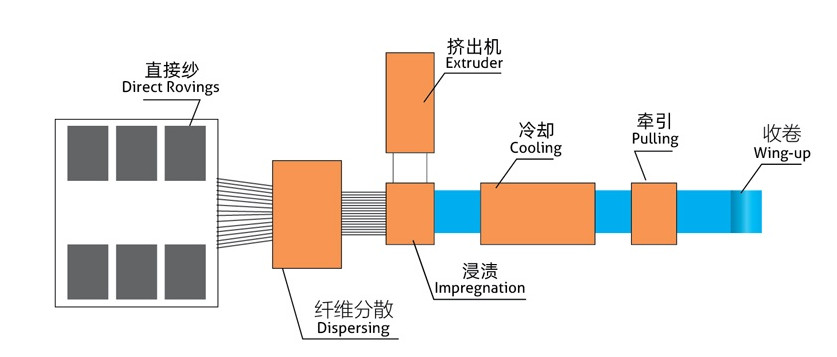

Direct Roving for Continuous Fiber Reinforced Thermoplastics is used for CFRT process.Fiberglass yarns were outside unwound from the bobbins on the shelf and then arranged in the same direction; Yarns were dispersed by tension and heated by hot air or IR; Molten thermoplastic compound was provided by an extruder and impregnated the fiberglass by pressure; After cooling, the final CFRT sheet was formed.

Features

●No fuzz

●Compatibility with a multiple of resin systems

●Good processing

●Excellent dispersion

●Excellent mechanical properties

Application:

It is used as automotive,construction, transportation and aeronautics.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

| BHCFRT-01D | 300-2400 | PA, PBT, PET, TPU, ABS | Compatibility with a multiple of resin systems, low fuzz | automotive,construction, transportation and aeronautics |

| BHCFRT-02D | 400-2400 | PP, PE | Excellent dispersion, excellent mechanical properties | automotive, construction,sports, electric ,and electronic |

| Identification | ||||

| Type of Glass |

E |

|||

| Direct Roving |

R |

|||

| Filament Diameter, μm | 400 | 600 | 1200 | 2400 |

| Linear Density, tex | 16 | 16 | 17 | 17 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/Tex) |

|

ISO1889 |

ISO3344 |

ISO1887 |

IS03341 |

|

±5 |

≤0.10 |

0.55±0.15 |

≥0.3 |

CFRT Process

A molten mixture of polymer resin and additives is obtained through an extruder . The continuous filament roving is dispersed and impregnatedby pulling through the molten mixture After cooling , curing and coiling .the final material is formed