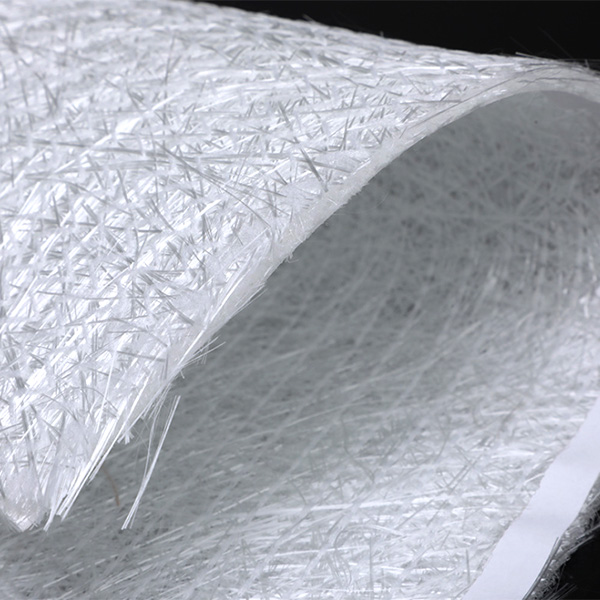

China Cheap price Glass Fiber Powder Chopped Strand Mat - Fiberglass Chopped Strand Mat Emulsion Binder – Beihai Fiberglass

China Cheap price Glass Fiber Powder Chopped Strand Mat - Fiberglass Chopped Strand Mat Emulsion Binder – Beihai Fiberglass Detail:

E-Glass Emulsion Chopped Strand Mat is made of randomly distributed chopped strands held tighter by a emulsion binder. It is compatible with UP, VE, EP resins.The roll width ranges from 50mm to 3300mm.

Product Features

● Fast breakdown in styrene

● High tensile strength, allowing for use in hand lay-up process to produce large-area parts

● Good wet-through and fast wet-out in resins, rapid air release

● Superior acid corrosion resistance

Application

Its end-use applications include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components.

Additional demands on wet-out and decomposition time may be available upon request. It is designed for use in hand lay-up, filament winding, compression molding and continuous laminating processes.

Product Specifications:

|

Property |

Area Weight |

Moisture Content |

Size Content |

Breakage Strength |

Width |

|

(%) |

(%) |

(%) |

(N) |

(mm) |

|

|

Mathods |

IS03374 |

ISO3344 |

ISO1887 |

ISO3342 |

50-3300 |

|

EMC80E |

±7.5 |

≤0.20 |

8-12 |

≥40 |

|

|

EMC100E |

≥40 |

||||

|

EMC120E |

≥50 |

||||

|

EMC150E |

4-8 |

≥50 |

|||

|

EMC180E |

≥60 |

||||

|

EMC200E |

≥60 |

||||

|

EMC225E |

≥60 |

||||

|

EMC300E |

3-4 |

≥90 |

|||

|

EMC450E |

≥120 |

||||

|

EMC600E |

≥150 |

||||

|

EMC900E |

≥200 |

● Special specification can be produce according to customer requirements.

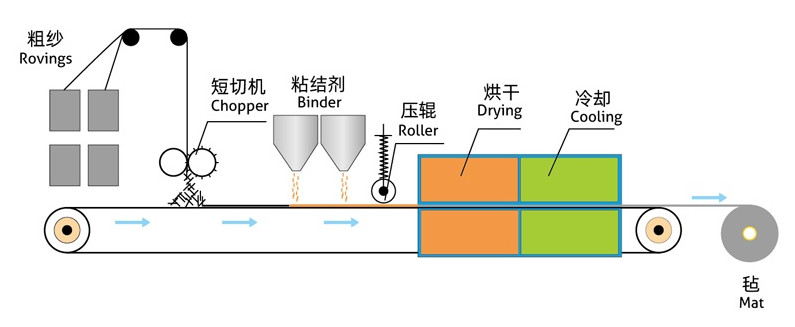

Mat Production Process

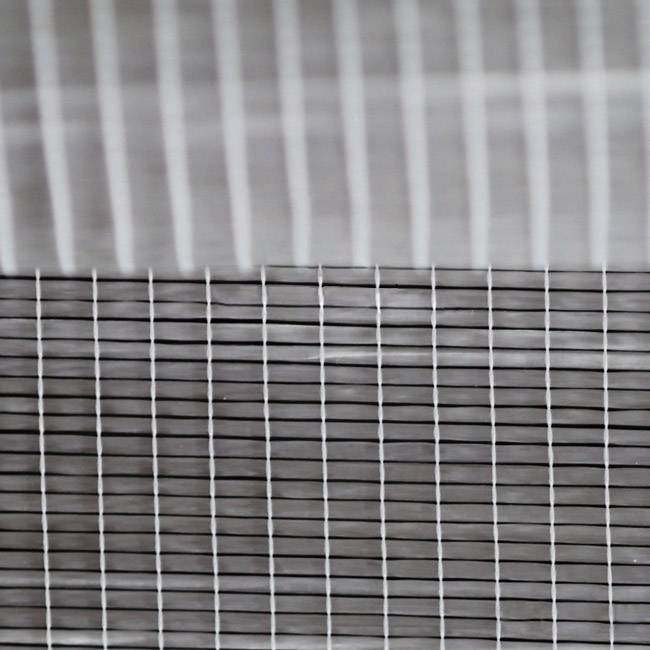

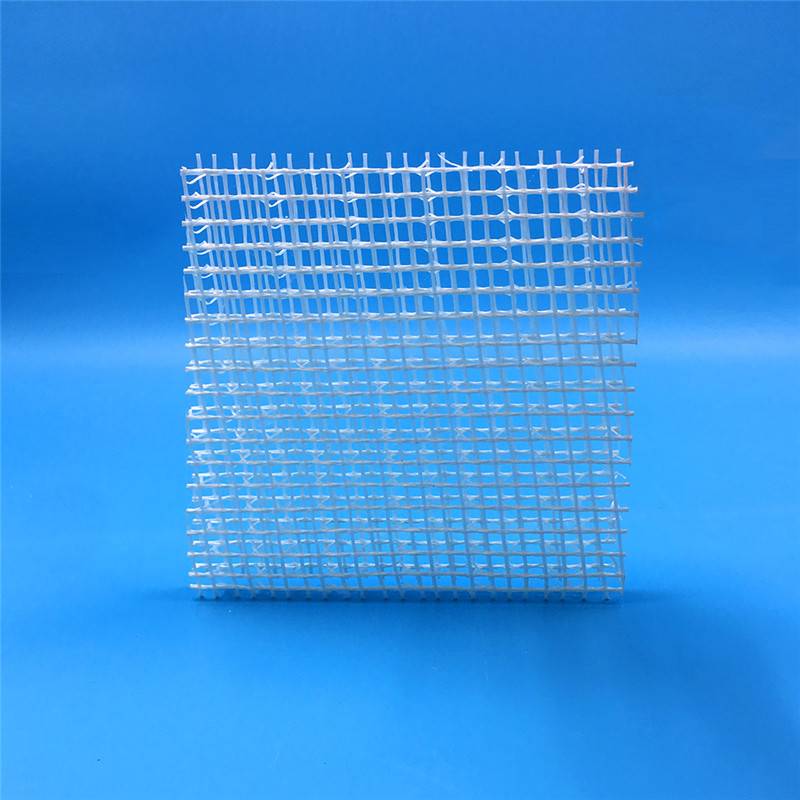

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly.

The chopped strands are bonded together by either an emulsion binder or a powder binder.

After drying, cooling and winding, a chopped stand mat is formed.

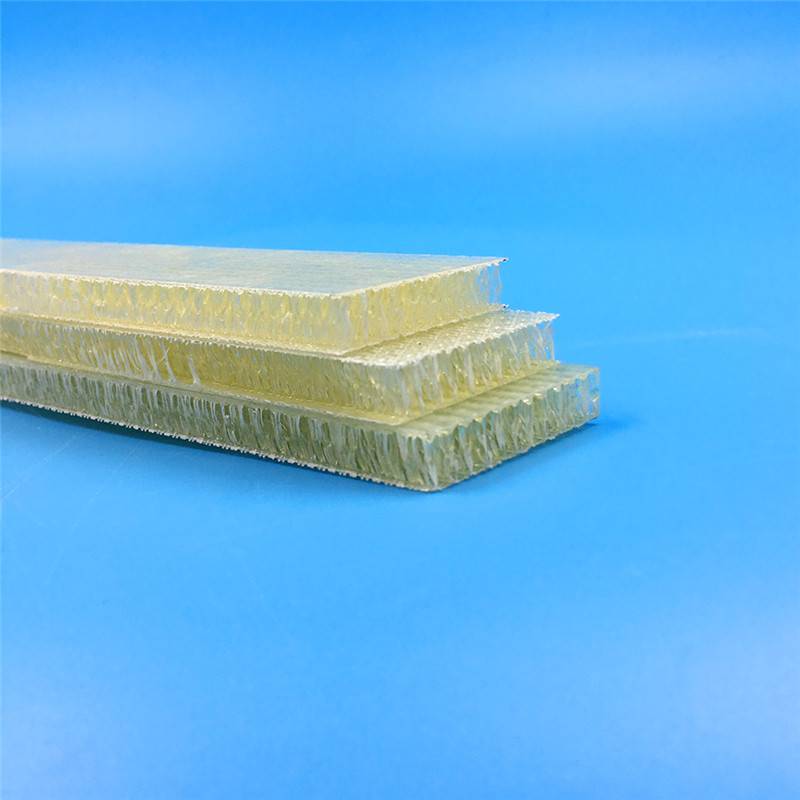

Packaging

Each Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 275mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

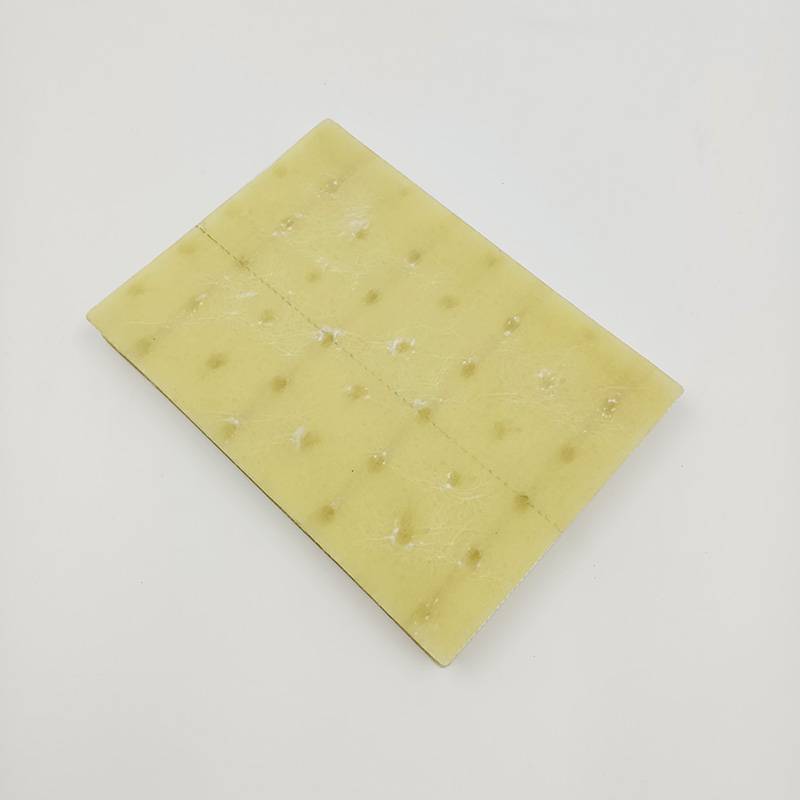

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for China Cheap price Glass Fiber Powder Chopped Strand Mat - Fiberglass Chopped Strand Mat Emulsion Binder – Beihai Fiberglass , The product will supply to all over the world, such as: Norwegian, Chile, Mumbai, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.