E-glass Assembled Roving For Centrifugal Casting

E-glass Assembled Roving For Centrifugal Casting

Assembled Roving for Centrifugal Casting is coated with silane-based sizing, compatible with UP resin, delivering excellent choppability and dispersion, low static , fast wet out, and excellent mechanical properties of the composite products.

Features

●Excellent choppability and dispersion

●Low static

●Fast wet out

●Excellent mechnical properties of composite products

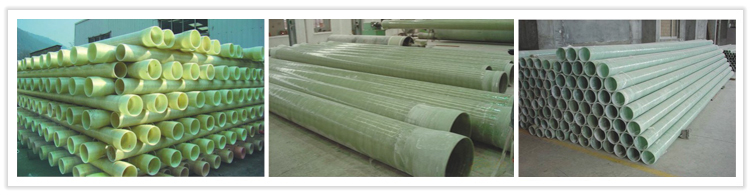

Application

Mainly used to produce HOBAS pipes of various specifications and can greatly enhance the strength of FRP pipes.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHCC-01A |

2400, 4800 |

UP |

fast wet out, low resin absorbability |

centrifugal casting pipe |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

0.95±0.15 |

130±20 |

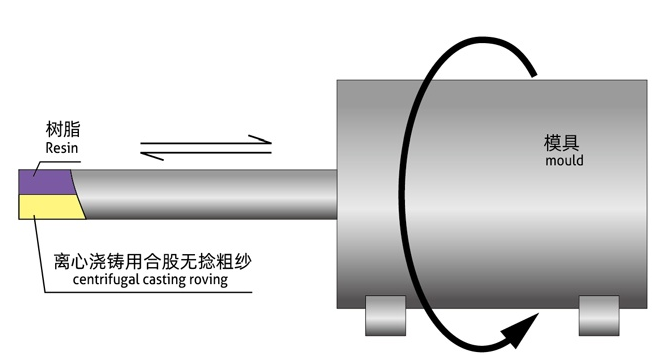

Centrifugal Casting Process

The raw materials , including resin , chopped reinforcement ( fiberglass ) , and filler , are fed into the interior of a rotating mould according to a specific proportion . Due to centrifugal force the materials are pressed against the wall of the mould under pressure , and the compound materials are compacted and deaired .After curing the composite part is removed from the mould