Bulk Phenolic Fiberglass Molding Compound

Product Introduction

Bulk phenolic glass fiber molding compound is a thermosetting molding compound made of phenolic resin as the base material, reinforced with glass fibers, and made by impregnation, mixing and other processes. Its composition usually includes phenolic resin (binder), glass fiber (reinforcing material), mineral filler and other additives (such as flame retardant, mold release agent, etc.).

Performance Characteristics

(1) Excellent mechanical properties

High bending strength: some products can reach 790 MPa (far exceeding the national standard ≥ 450 MPa).

Impact resistance: notched impact strength ≥ 45 kJ/m², suitable for parts subject to dynamic loads.

Heat resistance: Martin heat-resistant temperature ≥ 280 ℃, good dimensional stability at high temperatures, suitable for high-temperature environmental applications.

(2) Electrical insulation properties

Surface resistivity: ≥1×10¹² Ω, volume resistivity ≥1×10¹⁰ Ω-m, to meet the high insulation needs.

Arc resistance: some products have arc resistance time ≥180 seconds, suitable for high-voltage electrical components.

(3) Corrosion resistance and flame retardancy

Corrosion resistance: moisture and mildew resistant, suitable for hot and humid or chemically corrosive environments.

Flame-retardant grade: some products have reached UL94 V0 grade, non-combustible in case of fire, low smoke and non-toxic.

(4) Processing adaptability

Molding method: support injection molding, transfer molding, compression molding and other processes, suitable for complex structural components.

Low shrinkage: molding shrinkage ≤ 0.15%, high molding precision, reducing the need for post-processing.

Technical Parameters

The following are some of the technical parameters of typical products:

| Item | Indicator |

| Density (g/cm³) | 1.60~1.85 |

| Bending strength (MPa) | ≥130~790 |

| Surface Resistivity (Ω) | ≥1×10¹² |

| Dielectric loss factor (1MHz) | ≤0.03~0.04 |

| Water absorption (mg) | ≤20 |

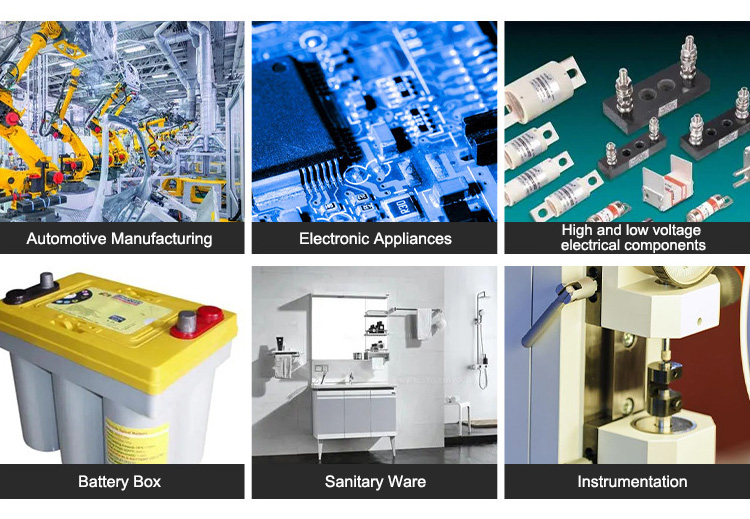

Applications

- Electromechanical industry: Manufacture of high-strength insulating parts such as motor shells, contactors, commutators, etc.

- Automotive industry: used in engine parts, body structure parts, to improve heat resistance and light weight.

- Aerospace: high temperature resistant structural parts, such as rocket parts.

- Electronic and electrical appliances: high-voltage insulation parts, switch housing, to meet the requirements of flame retardant and electrical performance.

Processing and Storage Precautions

Pressing process: temperature 150±5℃, pressure 350±50 kg/cm², time 1~1.5 min/mm.

Storage condition: Protect from light and moisture, storage period ≤ 3 months, bake at 90℃ for 2~4 minutes after moisture.