BMC

E-Glass Chopped Strands for BMC are specially designed for reinforcing unsaturated polyester, epoxy resin and phenolic resins.

Features

●Good strand integrity

●Low static and fuzz

●Fast and uniform distribution in resins

●Excellent mechanical and processing properties

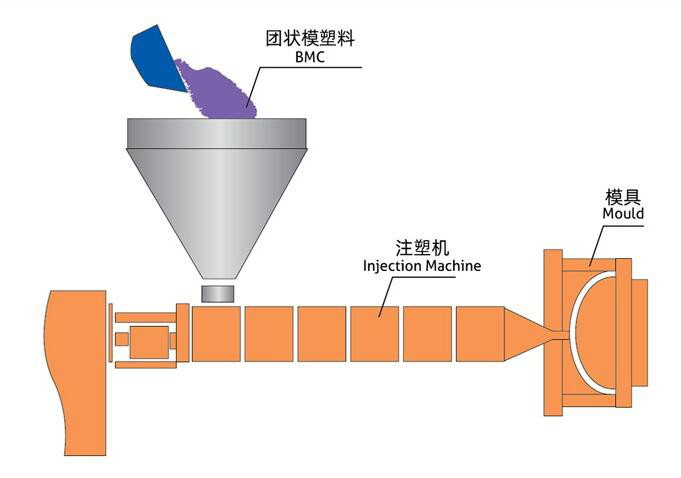

BMC Process

A bulk molding compound is made by combining glass chopped strands, resin, filler, catalyst and other additives, This compound is processed by compression molding or injection molding to form the finished composite parts.

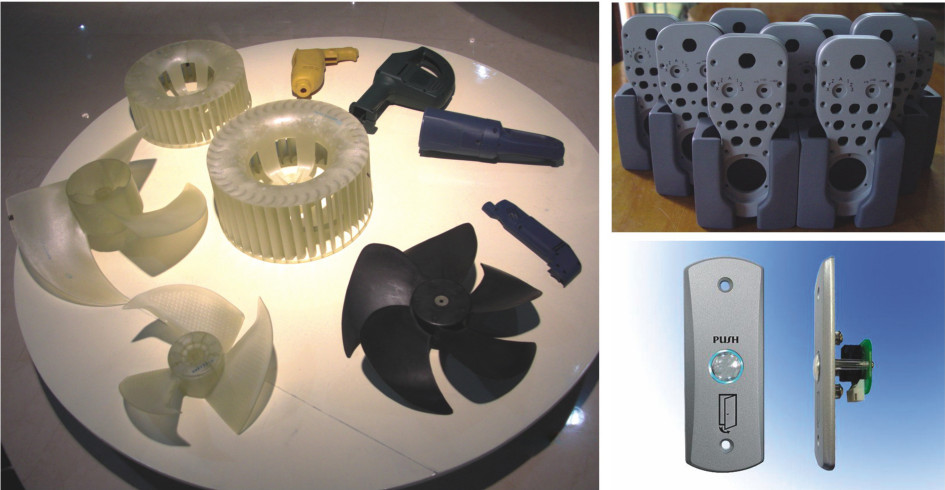

Application

E Glass Chopped Strands for BMC are widely used in transportation, construction, electronics,chemical industry and light industry. Such as the automotive parts, insulator and switch boxes.

Product List

|

Item No. |

Chop Length,mm |

Features |

Typical Application |

|

BH-01 |

3,4.5,6,12,25 |

High impact strength, high LOI rate |

Automotive parts, civilian electrical switches, electric tools, artificial marble platform boards and other products requiring high strength |

|

BH-02 |

3,4.5,6,12,25 |

Suitable for the dry mixing processing, high |

Friction materials, Products with superior friction coefficiency, including tires |

|

BH-03 |

3,4.5,6 |

Extremely low resin demand, delivering |

High fiberglass content products with complex structure and superior color, e.g., ceiling, artificial marble platform boards and lampshades |

Identification

|

Type of Glass |

E |

|

Chopped Strands |

CS |

|

Filament Diameter,μm |

13 |

|

Chop Length,mm |

3,4.5,6,12,18,25 |

|

Sizing Code |

BH-BMC |

Technical Parameters

|

Filament Diameter (%) |

Moisture Content (%) |

LOI Content (%) |

Chop length (mm) |

|

ISO1888 |

ISO3344 |

ISO1887 |

Q/BH J0361 |

|

±10 |

≤0.10 |

0.85±0.15 |

±1.0 |