When it comes to fiberglass reinforcements, rovings are a key component in various industries including construction, automotive, marine and aerospace. Woven roving consists of continuous fiberglass yarns woven in both directions, making it an ideal material for strength and flexibility. In this blog, we will explore the versatility of fiberglass woven roving and discuss where and why it is used in different applications.

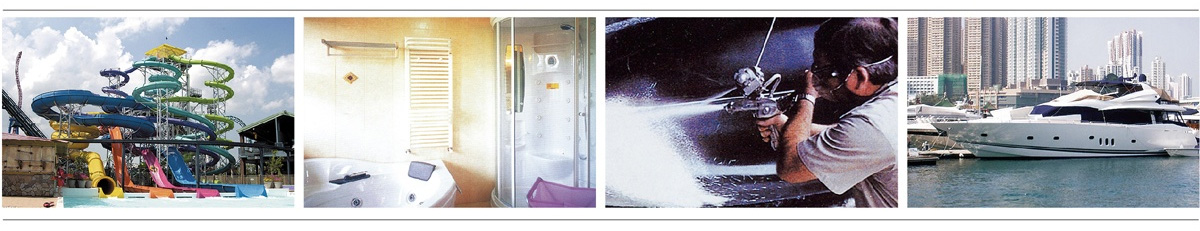

One of the most common uses for fiberglass woven roving is in the construction industry. It is widely used in the manufacture of fiberglass panels, pipes and tanks. The high strength and stiffness of woven roving make it an excellent material for reinforcing concrete structures, providing durability and resistance to environmental factors. Additionally, its non-corrosive properties make it ideal for use in chemical plants and industrial facilities.

In the automotive industry, fiberglass woven rovings are used to produce lightweight and durable components such as body panels, hoods and spoilers. Its high strength-to-weight ratio and impact resistance make it a popular choice for manufacturers looking to improve fuel efficiency and overall vehicle performance. Additionally, the ability to mold materials into complex shapes and designs opens up endless possibilities for automotive design.

In the marine industry, fiberglass woven rovings are an important material in building strong and resilient hulls and structures. It is water-resistant, corrosion-resistant, UV-resistant and ideal for marine applications. The flexibility of woven roving allows seamless integration into a variety of boat designs, providing strength and beauty.

In the aerospace industry, fiberglass woven rovings are used to make composites for aircraft components. The material’s high tensile strength and stiffness play a key role in providing structural integrity and durability during extreme flight conditions. Its lightweight properties also help improve fuel efficiency and overall performance, making it a valuable material in the aerospace industry.

So, where is twistless roving used? The answer is that it can be used in a wide range of applications, from construction to automotive, marine and aerospace. Its versatility, strength and flexibility make it ideal for reinforcing a variety of structures and components. Whether reinforcing concrete, building lightweight vehicle components, building durable boat hulls or producing high-performance aircraft components, fiberglass woven roving is a reliable and efficient material.

In conclusion, fiberglass roving is a versatile and essential material in many industries. Its strength, flexibility and resistance to environmental factors make it ideal for a variety of applications. As technology and innovation continue to advance, the use of fiberglass woven rovings may expand into new and exciting areas, further demonstrating its value and significance in the modern world.

Post time: Jan-18-2024