Fiber length precision, high fiber amount, monofilament diameter is consistent, the fiber in the dispersion of the segment before keeping a good mobility, because it is inorganic, so do not produce static electricity, high temperature resistance, in the product of the tensile force is consistent, can form a three-dimensional three-dimensional mesh structure, so that the product has a very good capricious and tensile family name, impact strength is high, the fiber is dispersed in the product of each corner of the length of the uniformity, so that the product of the tensile force The tensile strength of the product is consistent. And fiberglass fine powder can not be done, because it is crushed process, the length of the fiber can not be guaranteed, there are long and short, and powder, because it is scraps, in which there are many impurities, monofilament diameter is not guaranteed, the fiber has a thick and thin, so after the addition of the product, the strength can not be guaranteed, the strength of each corner of the value of the strength of the different, but also easy to stagger up the group.

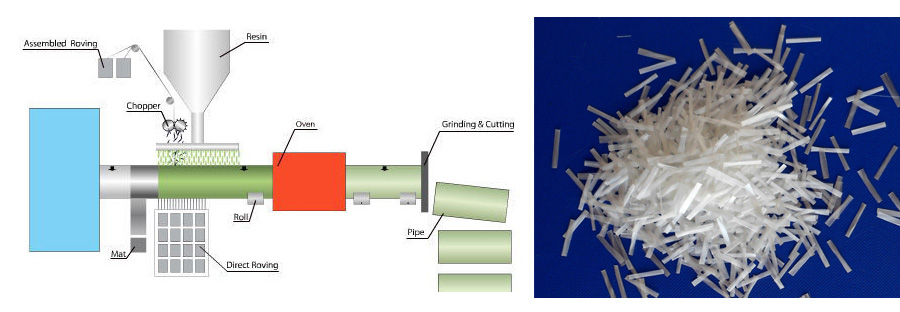

Fiberglass chopped strands Main Ingredients

Its main components are silica, alumina, calcium oxide, boron oxide, magnesium oxide, sodium oxide, etc., according to the amount of alkali content in the glass can be divided into non-alkali fiberglass (sodium oxide 0% to 2%, is an aluminum borosilicate glass), medium-alkali fiberglass staple (sodium oxide 8% to 12%, is a boron or boron free soda lime silicate glass) and high alkali glass fibers (more than 13% of sodium oxide, is a soda lime silicate glass). Silicate glass).

Fiberglass chopped strands according to the form and length, can be divided into continuous fiber, fixed-length fiber and glass wool; according to the glass composition, can be divided into alkali-free, chemical-resistant, high-alkali, alkali, high-strength, high modulus of elasticity and alkali-resistant glass fibers and so on.

Post time: Apr-23-2024