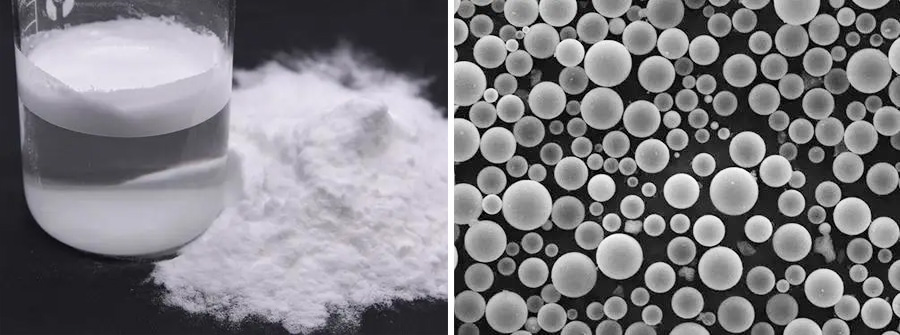

Hollow glass microspheres are used as a hollow, lightweight and high strength multifunctional filler in a wide range of functional coatings. The addition of hollow glass microspheres in coatings can meet more specific performance requirements, enabling the coatings to be used in a variety of heavy-duty anticorrosive and special acoustic and thermal insulation areas.

Role of hollow glass microspheres in coatings:

Good color:

Hollow glass microspheres are pure white and have certain matting, whitening and masking effects when applied in coatings.

Lower density:

Hollow glass microspheres have low density, which can reduce the weight of the coating in the coating, thus reducing the load and material cost.

Good thermal insulation:

The interior of hollow glass microspheres is inert gas, and there are density and thermal conductivity differences between the two different materials, which makes them characterized by heat insulation, sound insulation and low thermal conductivity. Hollow glass microspheres have low air heat transfer coefficient, forming a dense thermal barrier layer in the coating, which can effectively retard the transfer of heat to the building body, is a commonly used thermal barrier filler in coatings, and can be used for filling of various heat-insulating and thermal-retaining coatings. Hollow glass microspheres can also be used to protect the coating film from thermal shocks caused by alternating changes between hot and cold conditions.

Good flowability and dimensional stability:

Hollow glass microspheres are tiny round balls that are easily dispersed and have good flow and leveling in coatings. Moreover, the round spheres are isotropic, which can avoid shrinkage and warping of the coating.

Improvement of paint film performance

The structure of hollow glass microspheres in spherical shape can well disperse the impact and stress, so that the coating has certain anti-external impact characteristics, and at the same time, it can reduce the stress cracking of the coating due to thermal expansion and contraction.

Higher resin substitution rate, lower cost

Hollow glass microspheres have high specific surface area and low oil absorption rate, which have good dispersibility and filling in coatings. The low oil absorption rate can greatly increase the dosage of fillers, reduce the dosage of resin, and realize highly efficient filling without increasing or even decreasing the cost per unit volume of coatings.

Examples of applications of hollow glass microspheres in the field of coatings:

Heavy anti-corrosion coatings:

Hollow glass microspheres can be applied in epoxy zinc rich coatings and play an important role in coatings. The volume effect of hollow glass microspheres helps to improve the dispersion of zinc powder. Their spherical structure not only improves the fluidity of the paint but also prevents the film from shrinking or warping due to stress inconsistencies and improves impact resistance. Hollow glass microspheres in the paint film can also shield corrosion products, such as chlorides, oxides, etc., thus preventing corrosive substances from coming into contact with the substrate, so that the substrate to obtain stable long-term protection.

Thermal insulation paint:

Hollow glass microspheres have a low thermal conductivity, in the paint thermal insulation performance has a broad application prospects. For example, when used in exterior reflective thermal insulation coatings, they can reflect sunlight and have good reflective thermal insulation effect. The low thermal conductivity of hollow glass microspheres can also be used to prepare temperature resistant coatings.

Anti-stoning coatings (automobile primer):

Hollow glass microspheres can be used in PVC anti-rock impact coatings, its hollow structure, in the impact will absorb, digest the impact strength, improve the impact resistance of the material, at the same time, hollow glass microspheres have a lower density, for cost reduction and automobile lightweight also plays an important role.

As a new type of filler material, hollow glass microspheres have unique structural characteristics that make them widely used in various fields. By adding hollow glass microspheres, the performance of coatings can be improved and the function of coatings can be extended. The excellent performance of hollow glass microspheres makes them have a broader application prospect.

Post time: Aug-28-2024