Best quality E-Glass Fiber Roving - E-glass Assembled Roving For GMT – Beihai Fiberglass

Best quality E-Glass Fiber Roving - E-glass Assembled Roving For GMT – Beihai Fiberglass Detail:

E-glass Assembled Roving For Spray up

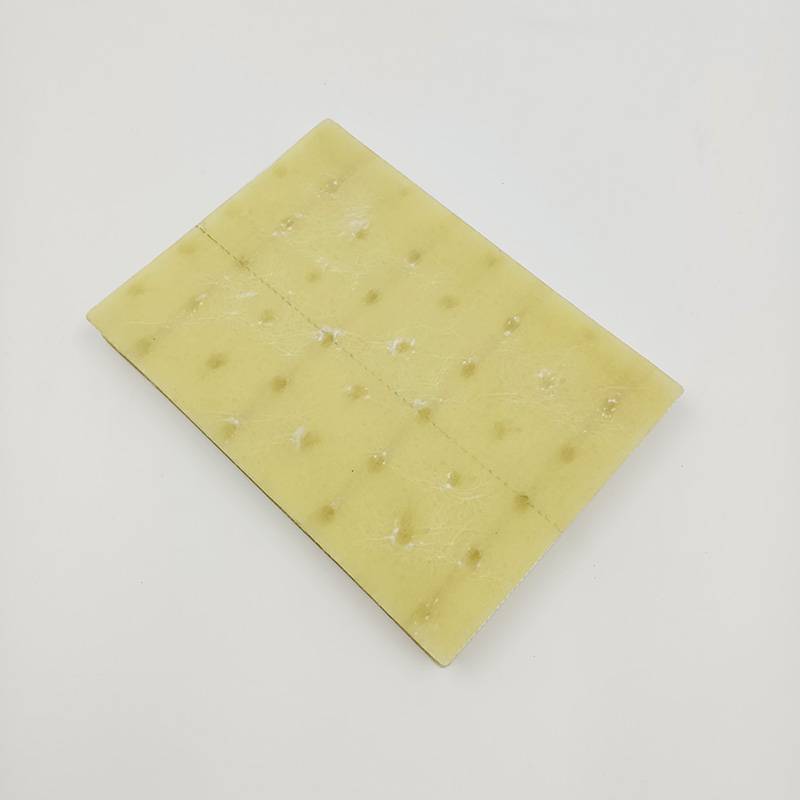

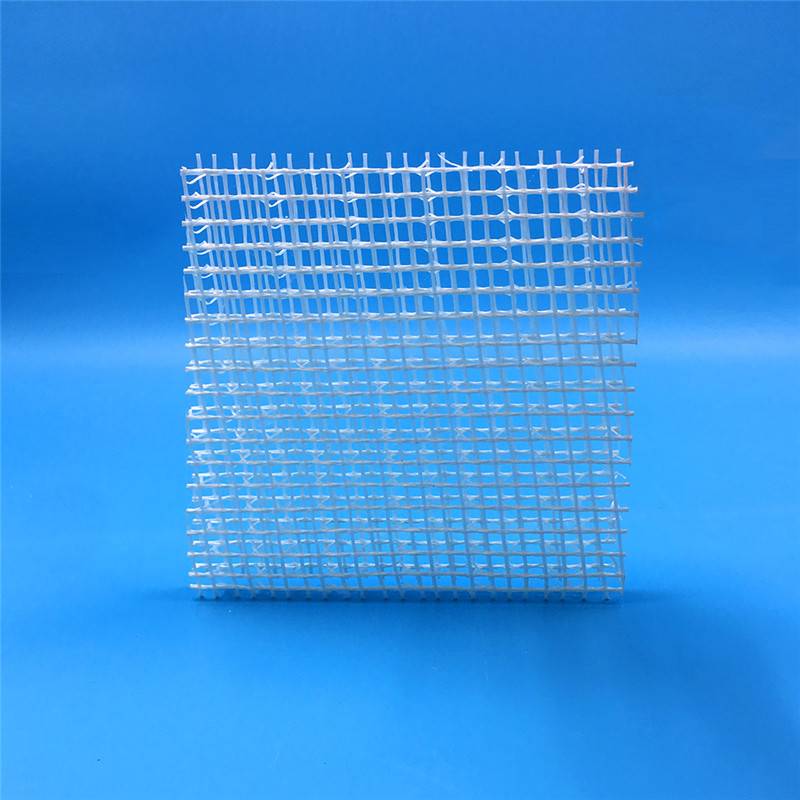

Assembled Roving for spray-up is compatible with UP and VE resins. It delivers properties of low static, excellent dispersion, and good wet out in resins.

Features

●Low static

●Excellent dispersion

●Good wet-out in resins

Application

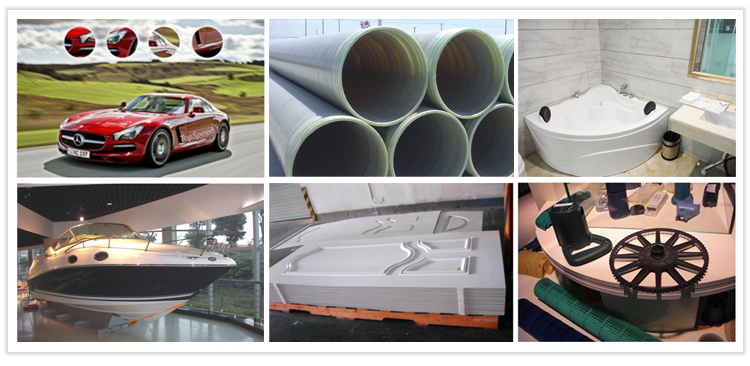

It covers a wide range of applications: bathtub, FRP boat hulls, various pipes, storage vessels and cooling towers.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHSU-01A |

2400, 4800 |

UP, VE |

fast wet out, easy roll-out, optimum dispersion |

bathtub, supporting components |

|

BHSU-02A |

2400, 4800 |

UP, VE |

easy roll-out, no spring-back |

bathroom equipment, yacht components |

|

BHSU-03A |

2400, 4800 |

UP, VE, PU |

fast wet out, excellent mechanical and water resistance property |

bathtub, FRP boat hull |

|

BHSU-04A |

2400, 4800 |

UP, VE |

moderate wet out speed |

swimming pool, bathtub |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

11, 12, 13 |

| Linear Density, tex |

2400, 3000 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.05±0.15 |

135±20 |

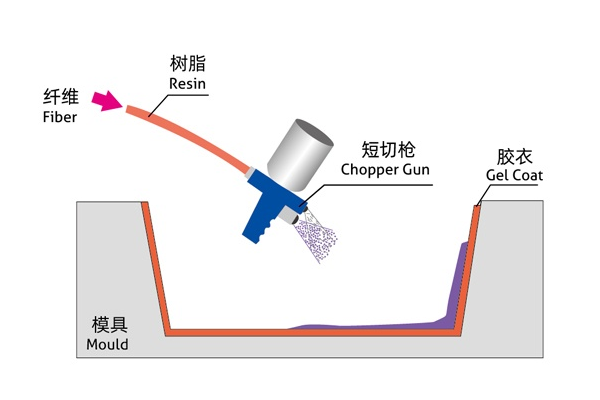

Spray-up Process

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving ( fiberglass cut to specific length using a chopper gun ) . Then the glass-resin mixture is well compacted , usually manually , for complete impregnation and deairing . After curing the finished composite part is de-molded

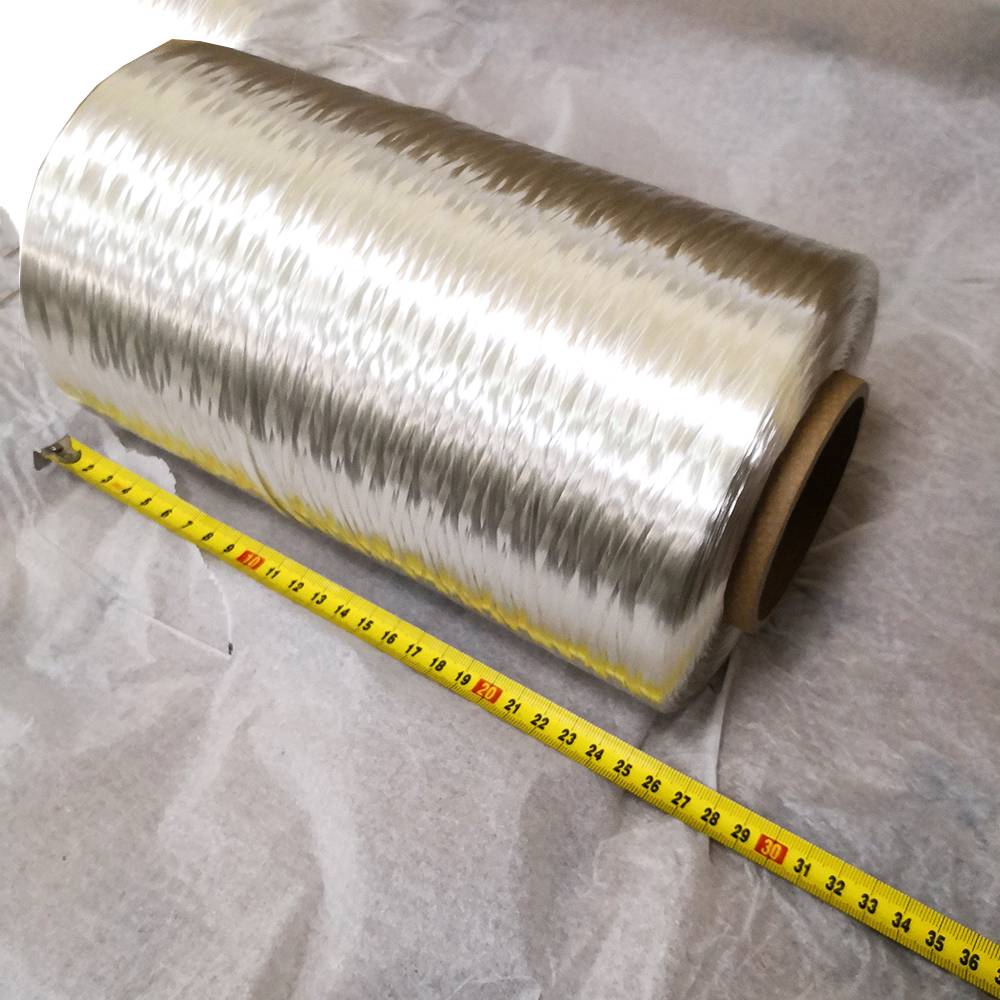

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for Best quality E-Glass Fiber Roving - E-glass Assembled Roving For GMT – Beihai Fiberglass , The product will supply to all over the world, such as: Israel, Jamaica, Amsterdam, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.