Basalt Fibre Rebar BFRP Composite Rebar

Product Description

Basalt Fiber Reinforcement, also known as BFRP (Basalt Fiber Reinforced Polymer) composite reinforcement, is a composite reinforcement consisting of basalt fibres and a polymer matrix.

Product Characteristics

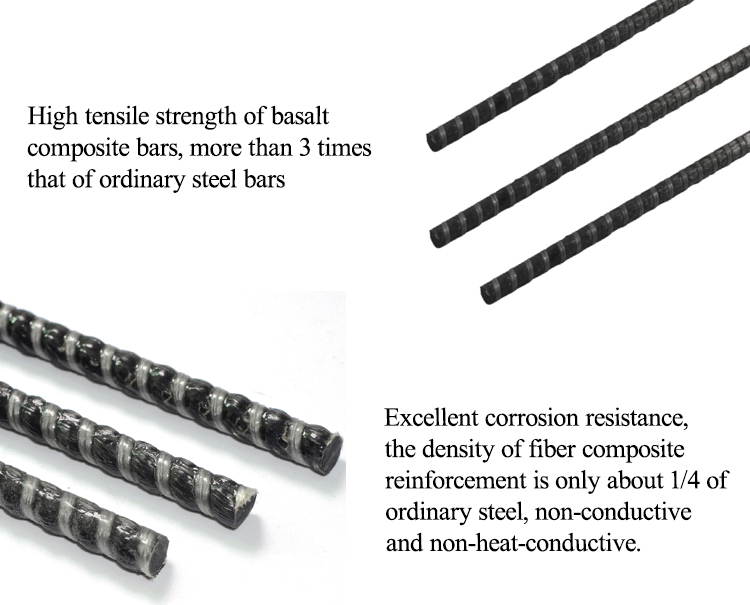

1. High Strength: BFRP composite reinforcement has excellent strength characteristics, and its strength is higher than that of steel. The high strength and stiffness of the basalt fibres enable BFRP composite reinforcement to effectively increase the load-bearing capacity of concrete structures.

2. Lightweight: BFRP composite reinforcement has a lower density than conventional steel reinforcement and is therefore lighter. This allows the use of BFRP composite reinforcement in construction to reduce structural loads, simplify the construction process and reduce transport costs.

3. Corrosion resistance: Basalt fibre is an inorganic fibre with good corrosion resistance. Compared to steel reinforcement, BFRP composite reinforcement will not corrode in corrosive environments such as humidity, acid and alkali, which prolongs the service life of the structure.

4. Thermal stability: BFRP composite reinforcement has good thermal stability and is able to maintain its strength and stiffness in high temperature environments. This gives it an advantage in high-temperature engineering applications such as fire protection and structural reinforcement in high-temperature areas.

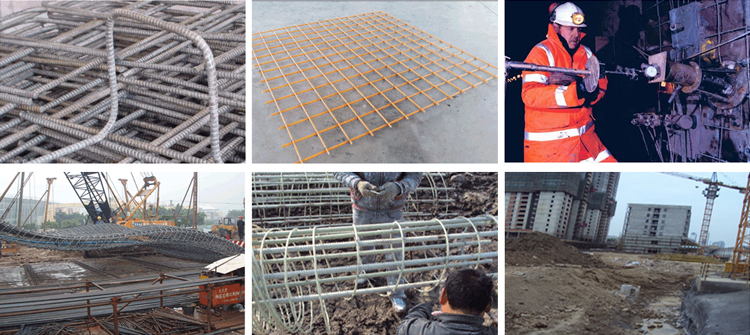

5. Customisability: BFRP composite reinforcement can be custom manufactured according to project requirements, including different diameters, shapes and lengths. This makes it suitable for reinforcement and strengthening of various concrete structures, such as bridges, buildings, water projects, etc.

As a new type of reinforcing material with good mechanical properties and durability, BFRP composite reinforcement is widely used in engineering fields. It can replace the traditional steel reinforcement to reduce the project cost and improve the construction efficiency to a certain extent, as well as to meet the structural requirements for lightweight, corrosion-resistant and high-strength.